rutile titanium dioxide industry grade for paint suppliers

In the warehouse, proper storage facilities are critical to prevent dust accumulation and potential fire hazards. This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area

This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards.

wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards.

The manufacturing process of TIO2 pigment involves either the sulfate or chloride process. Each method yields different types of TIO2 particles, which can affect the final product's performance and application. The sulfate process typically produces anatase, a crystalline form of TIO2, while the chloride process yields rutile, another crystalline form known for its superior durability and refractive index.

When it comes to advanced materials, micro TiO2's photocatalytic properties have sparked interest in renewable energy and environmental remediation. In solar cells, it serves as an effective electron conductor, while in self-cleaning surfaces, it breaks down organic pollutants upon exposure to sunlight.

When it comes to suppliers, China stands out as the major global producer and exporter of lithopone, accounting for a substantial portion of the world's supply. Chinese suppliers, known for their competitive pricing and large-scale production, have a significant influence on the global market. Companies such as Zhejiang Yinfeng Chemical Co., Ltd., Zhejiang Huayi Chemical Co., Ltd., and Shaanxi Jintai Group Co, and Shaanxi Jintai Group Co , and Shaanxi Jintai Group Co, and Shaanxi Jintai Group Co

, and Shaanxi Jintai Group Co, and Shaanxi Jintai Group Co lithopone prices suppliers., Ltd. are some of the key players in the industry.

lithopone prices suppliers., Ltd. are some of the key players in the industry.

Availability of alternative inorganic white pigments, mainly Titanium Dioxide (TiO2) pigments

...

2025-08-15 19:00

2984

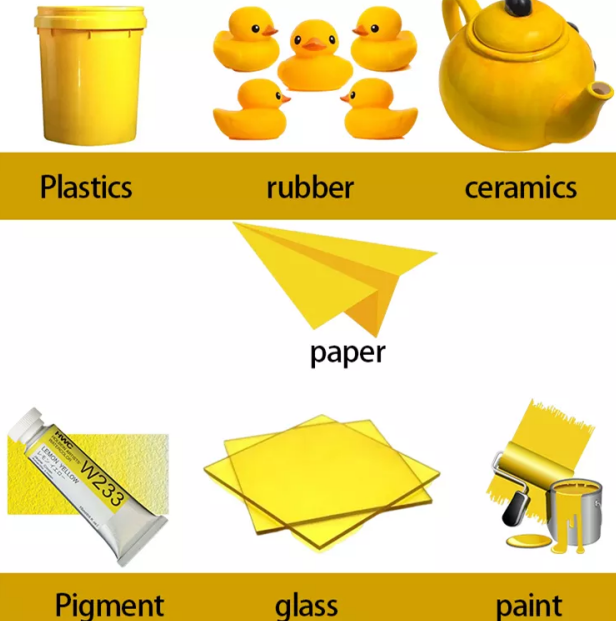

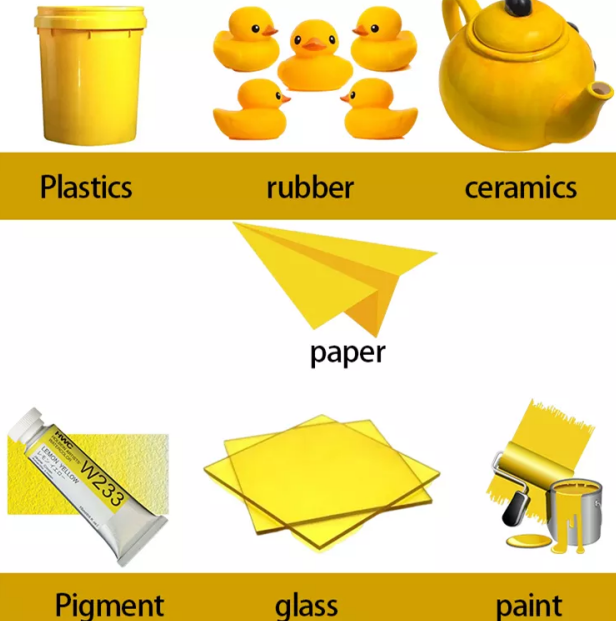

In the paper industry, TiO2 is used to create high-quality, bright white paper products. By adding TiO2 to pulp, paper manufacturers can improve the opacity, brightness, and printability of their products. TiO2 also enhances the lightfastness and aging resistance of paper, ensuring that it maintains its appearance and quality over time. With TiO2, paper products can achieve a superior level of whiteness and visual appeal.

...

2025-08-15 18:58

112

Applications of Lithopone Powder:

...

2025-08-15 18:54

2087

...

2025-08-15 18:41

1868

In the paper industry, TiO2 is used to create high-quality, bright white paper products. By adding TiO2 to pulp, paper manufacturers can improve the opacity, brightness, and printability of their products. TiO2 also enhances the lightfastness and aging resistance of paper, ensuring that it maintains its appearance and quality over time. With TiO2, paper products can achieve a superior level of whiteness and visual appeal.

Applications of Lithopone Powder:

No acute effects of nano-sized TiO2 were observed in Danio rerio (zebrafish) embryos. Exposure of rainbow trout to TiO2 NPs triggered lipid peroxidation, influence on the respiratory tract, disturbance in the metabolism of Cu and Zn, induction of intestinal erosion and accumulation in kidney tissue. Linhua et al. exposed juvenile carp to 100 and 200 mg/ml of particles and TiO2 observed no mortality. However, the fish suffered from oxidative stress and pathological changes in gill and liver. In the infaunal species Arenicola marina, exposure to TiO2 NPs in sediment caused sub-lethal effects including decrease in casting rate and increase in cellular and DNA damage. Aggregated particles were visible in the lumen of the gut, but no uptake through the gut or the skin was observed.

Furthermore, Chinese lithopone manufacturers are known for their innovation and advancement in production technologies. They invest in research and development to continuously improve their manufacturing processes and develop new and improved grades of lithopone. This focus on innovation has enabled Chinese manufacturers to stay ahead of the competition and remain at the forefront of the industry.

- Lithopone, a crucial component in the manufacturing of various industrial products, is a mixture of zinc sulfide and barium sulfate. It is widely used as a white pigment in paints, plastics, printing inks, and many other applications due to its excellent opacity and light stability. The global lithopone market, therefore, plays a significant role in the worldwide chemical industry.

- In conclusion, the evolution of titanium dioxide production towards greater sustainability signifies a crucial milestone in industrial ecology. With the integration of cleaner technologies and renewable energy, factories are redefining what it means to offer the best titanium dioxide at an eco-friendly price. As we move forward, the commitment of these manufacturers will undoubtedly play a vital role in safeguarding our environment for generations to come.

- Furthermore, inner wall coating factories are investing in research and development to create coatings that are not only durable and aesthetically pleasing but also easy to apply. By developing coatings that are user-friendly and efficient, factories are able to cater to the needs of both professional contractors and DIY enthusiasts.

- However, the dissolution of titanium dioxide in oil isn't without challenges. The process requires precise control to ensure proper dispersion and prevent particle aggregation. Moreover, the potential health and environmental concerns associated with TiO2 exposure necessitate strict adherence to safety protocols during handling and disposal.

To be added to food, this additive must achieve 99% purity. However, this leaves room for small amounts of potential contaminants like lead, arsenic, or mercury (1Trusted Source).

The conjugation of vitamin C to the P25TiO2NPs was confirmed by UV-visible spectroscopy of lyophilized vitaminC@P25TiO2NPs suspensions. The typical absorbance peak of ascorbic acid at 265 nm was found. However, no further characterization was done because they did not show the expected protective effect against the photo-induced cell damage (Fig. 3).

- There are numerous TiO2 concrete suppliers globally, each committed to providing high-quality products to meet the specific requirements of their clients. These suppliers source their TiO2 from reputable mines and processing facilities, ensuring consistency and reliability in their supply chain. They understand that the quality of TiO2 can significantly impact the overall performance and aesthetics of concrete structures.

- TR 92 titanium dioxide is known for its exceptional whiteness, which is important for achieving vibrant and long-lasting colors in paints and coatings. Its high opacity ensures excellent coverage, allowing for fewer coats and reducing overall costs. Additionally, TR 92 titanium dioxide is resistant to fading and degradation from UV exposure, making it suitable for outdoor applications.

To ensure the optimal precipitation percentage, it is important to carefully control these factors during the precipitation process. For example, a higher concentration of titanium sulfate will typically result in a higher precipitation percentage, but may also lead to the formation of impurities. On the other hand, a lower pH of the reaction mixture can promote the precipitation of titanium hydroxide, but may also result in a lower precipitation percentage.

- 3. Chemours This American chemical company specializes in producing TIO2 pigments for use in coatings, plastics, and other industrial applications.

- The rutile structure of our TiO2 powder is renowned for its exceptional optical properties and high refractive index, making it indispensable in applications where concealment or enhancement of other colors is desired. It is these characteristics that transform our TiO2 into an essential component within the broader industry.

- Avoid titanium dioxide in powdered cosmetics, including loose and pressed powders, eyeshadows, and blush.

So if you’re worried about titanium dioxide, don’t be! With current research and industry recommendations, titanium dioxide is a safe food additive. And if you want to avoid it, that’s ok too! Just don’t expect certain foods to be so white, smooth, and bright.

It doesn’t take much to imagine what they must be doing to our poor skin each day as we layer on our sunscreen, foundation, concealers, eyeshadows & lip sticks which all contain large doses of titanium dioxide.

- Calcium carbonate is a widely used chemical compound that plays a crucial role in various industries. It is commonly classified into different grades based on its purity and particle size distribution. One such classification is the wholesale classification of calcium carbonate, which categorizes it into different grades based on its quality and intended use.

- Moreover, these facilities are increasingly powered by renewable energy sources, further lessening their ecological footprint. Solar panels, wind turbines, and hydroelectric power are just some of the alternatives being adopted to fuel the transformation towards sustainable production. As a result, the cost of going green is becoming more accessible, allowing factories to pass on savings to customers without compromising the competitiveness of their eco-friendly prices.

- Looking ahead, the future of TiO2 industry factories appears poised for further advancement. Emerging trends such as the integration of nanotechnology and the exploration of alternative raw materials promise to revolutionize pigment properties and production processes. Additionally, the ongoing push for circular economy principles will likely result in increased recycling efforts within the industry, reducing reliance on virgin feedstocks and promoting a more sustainable business model.

- Furthermore, lithopone quotes are a nod to the harmonious relationship between technology and tradition in China. As a country that values both its rich heritage and technological advancements, the creation and preservation of such art forms demonstrate a commitment to honoring the past while embracing modernity. It's a unique blend that reflects the dynamic nature of Chinese society.

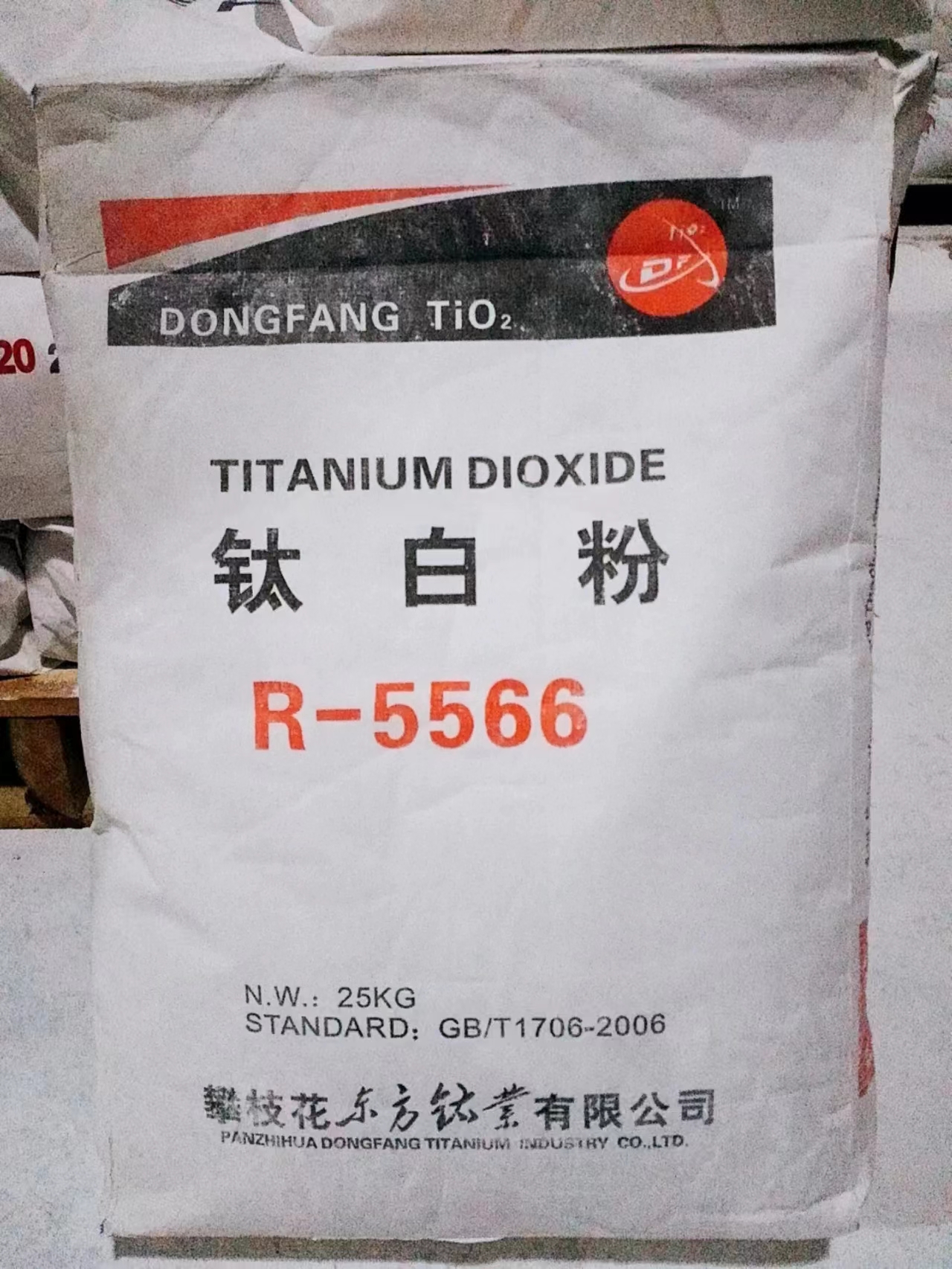

Free Sample TiO2 DongFang R5566 Titanium Dioxide

- 14

Increasing end-uses of rubber products: For instance, Evonik's TiO2 products are known for their excellent light scattering properties, while Tronox boasts a wide range of specialized grades designed for specific applications. Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management

Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management apakah titanium dioxide supplier.

apakah titanium dioxide supplier. In the application of lithopone in ink industry, lithopone has fine particles, loose structure, good fineness and good paint adhesion, so it can be well combined with other colors in the composition of ink.

It outlines the current Lithopone market trends and future estimations from 2019 to 2027 to understand the prevailing opportunities and potential investment pockets. Historically, the first mentions of zinc sulfide being utilized as a pigment were approximately sixty years before the everyday use of lithopone. Originally, it was thought to be appropriate for coloring rubber. In England, a patent was granted for this process. Two decades after this, the focus shifted to zinc sulfide as a suitable pigment for paint. The year 1874 witnessed the patenting of a manufacturing process for a novel white pigment composed of zinc sulfide and barium sulfate. Dubbed Charlton white or Orr’s white enamel, this began a new era for white pigments.

How pure TiO2 is extracted from titanium-containing molecules depends on the composition of the original mineral ores or feedstock. Two methods are used to manufacture pure TiO2: a sulphate process and a chloride process.

Environmental Considerations What’s recently changed with titanium dioxide and regulations?

No acute effects of nano-sized TiO2 were observed in Danio rerio (zebrafish) embryos. Exposure of rainbow trout to TiO2 NPs triggered lipid peroxidation, influence on the respiratory tract, disturbance in the metabolism of Cu and Zn, induction of intestinal erosion and accumulation in kidney tissue. Linhua et al. exposed juvenile carp to 100 and 200 mg/ml of particles and TiO2 observed no mortality. However, the fish suffered from oxidative stress and pathological changes in gill and liver. In the infaunal species Arenicola marina, exposure to TiO2 NPs in sediment caused sub-lethal effects including decrease in casting rate and increase in cellular and DNA damage. Aggregated particles were visible in the lumen of the gut, but no uptake through the gut or the skin was observed.

Furthermore, Chinese lithopone manufacturers are known for their innovation and advancement in production technologies. They invest in research and development to continuously improve their manufacturing processes and develop new and improved grades of lithopone. This focus on innovation has enabled Chinese manufacturers to stay ahead of the competition and remain at the forefront of the industry.

Furthermore, Chinese lithopone manufacturers are known for their innovation and advancement in production technologies. They invest in research and development to continuously improve their manufacturing processes and develop new and improved grades of lithopone. This focus on innovation has enabled Chinese manufacturers to stay ahead of the competition and remain at the forefront of the industry.

- Lithopone, a crucial component in the manufacturing of various industrial products, is a mixture of zinc sulfide and barium sulfate. It is widely used as a white pigment in paints, plastics, printing inks, and many other applications due to its excellent opacity and light stability. The global lithopone market, therefore, plays a significant role in the worldwide chemical industry.

- In conclusion, the evolution of titanium dioxide production towards greater sustainability signifies a crucial milestone in industrial ecology. With the integration of cleaner technologies and renewable energy, factories are redefining what it means to offer the best titanium dioxide at an eco-friendly price. As we move forward, the commitment of these manufacturers will undoubtedly play a vital role in safeguarding our environment for generations to come.

- Furthermore, inner wall coating factories are investing in research and development to create coatings that are not only durable and aesthetically pleasing but also easy to apply. By developing coatings that are user-friendly and efficient, factories are able to cater to the needs of both professional contractors and DIY enthusiasts.

- However, the dissolution of titanium dioxide in oil isn't without challenges. The process requires precise control to ensure proper dispersion and prevent particle aggregation. Moreover, the potential health and environmental concerns associated with TiO2 exposure necessitate strict adherence to safety protocols during handling and disposal.

To be added to food, this additive must achieve 99% purity. However, this leaves room for small amounts of potential contaminants like lead, arsenic, or mercury (1Trusted Source).

The conjugation of vitamin C to the P25TiO2NPs was confirmed by UV-visible spectroscopy of lyophilized vitaminC@P25TiO2NPs suspensions. The typical absorbance peak of ascorbic acid at 265 nm was found. However, no further characterization was done because they did not show the expected protective effect against the photo-induced cell damage (Fig. 3).

- There are numerous TiO2 concrete suppliers globally, each committed to providing high-quality products to meet the specific requirements of their clients. These suppliers source their TiO2 from reputable mines and processing facilities, ensuring consistency and reliability in their supply chain. They understand that the quality of TiO2 can significantly impact the overall performance and aesthetics of concrete structures.

- TR 92 titanium dioxide is known for its exceptional whiteness, which is important for achieving vibrant and long-lasting colors in paints and coatings. Its high opacity ensures excellent coverage, allowing for fewer coats and reducing overall costs. Additionally, TR 92 titanium dioxide is resistant to fading and degradation from UV exposure, making it suitable for outdoor applications.

To ensure the optimal precipitation percentage, it is important to carefully control these factors during the precipitation process. For example, a higher concentration of titanium sulfate will typically result in a higher precipitation percentage, but may also lead to the formation of impurities. On the other hand, a lower pH of the reaction mixture can promote the precipitation of titanium hydroxide, but may also result in a lower precipitation percentage.

- 3. Chemours This American chemical company specializes in producing TIO2 pigments for use in coatings, plastics, and other industrial applications.

- The rutile structure of our TiO2 powder is renowned for its exceptional optical properties and high refractive index, making it indispensable in applications where concealment or enhancement of other colors is desired. It is these characteristics that transform our TiO2 into an essential component within the broader industry.

- Avoid titanium dioxide in powdered cosmetics, including loose and pressed powders, eyeshadows, and blush.

So if you’re worried about titanium dioxide, don’t be! With current research and industry recommendations, titanium dioxide is a safe food additive. And if you want to avoid it, that’s ok too! Just don’t expect certain foods to be so white, smooth, and bright.

It doesn’t take much to imagine what they must be doing to our poor skin each day as we layer on our sunscreen, foundation, concealers, eyeshadows & lip sticks which all contain large doses of titanium dioxide.

- Calcium carbonate is a widely used chemical compound that plays a crucial role in various industries. It is commonly classified into different grades based on its purity and particle size distribution. One such classification is the wholesale classification of calcium carbonate, which categorizes it into different grades based on its quality and intended use.

- Moreover, these facilities are increasingly powered by renewable energy sources, further lessening their ecological footprint. Solar panels, wind turbines, and hydroelectric power are just some of the alternatives being adopted to fuel the transformation towards sustainable production. As a result, the cost of going green is becoming more accessible, allowing factories to pass on savings to customers without compromising the competitiveness of their eco-friendly prices.

- Looking ahead, the future of TiO2 industry factories appears poised for further advancement. Emerging trends such as the integration of nanotechnology and the exploration of alternative raw materials promise to revolutionize pigment properties and production processes. Additionally, the ongoing push for circular economy principles will likely result in increased recycling efforts within the industry, reducing reliance on virgin feedstocks and promoting a more sustainable business model.

- Furthermore, lithopone quotes are a nod to the harmonious relationship between technology and tradition in China. As a country that values both its rich heritage and technological advancements, the creation and preservation of such art forms demonstrate a commitment to honoring the past while embracing modernity. It's a unique blend that reflects the dynamic nature of Chinese society.

Free Sample TiO2 DongFang R5566 Titanium Dioxide

- 14

Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management

Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management Suppliers also invest in sustainability initiatives, given the environmental concerns associated with TiO2 production, such as energy consumption and waste management apakah titanium dioxide supplier.

apakah titanium dioxide supplier.In the application of lithopone in ink industry, lithopone has fine particles, loose structure, good fineness and good paint adhesion, so it can be well combined with other colors in the composition of ink.

Historically, the first mentions of zinc sulfide being utilized as a pigment were approximately sixty years before the everyday use of lithopone. Originally, it was thought to be appropriate for coloring rubber. In England, a patent was granted for this process. Two decades after this, the focus shifted to zinc sulfide as a suitable pigment for paint. The year 1874 witnessed the patenting of a manufacturing process for a novel white pigment composed of zinc sulfide and barium sulfate. Dubbed Charlton white or Orr’s white enamel, this began a new era for white pigments.

How pure TiO2 is extracted from titanium-containing molecules depends on the composition of the original mineral ores or feedstock. Two methods are used to manufacture pure TiO2: a sulphate process and a chloride process.

What’s recently changed with titanium dioxide and regulations?

Specific gravity:

Though the regulated use of titanium dioxide in food products is legal in the U.S. and Canada, it's banned in some other countries, notably throughout Europe. In May 2021, the European Food Safety Authority announced that titanium dioxide can no longer be considered safe as a food additive.