...

2025-08-14 16:31

2650

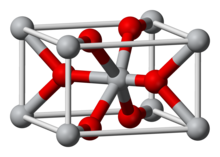

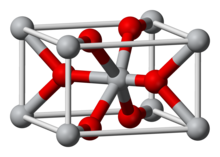

Titanium dioxide is used in an enormous range of food products, which can feel jarring when looking at some of its other uses.

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.

talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.