Residential Buildings: Aluminium window profiles are used in residential homes for their aesthetic appeal, energy efficiency, and resistance to weather conditions. They are ideal for creating custom window designs that suit individual preferences and architectural styles.

The Main Wrought Iron Fence Components Cast Iron Railing Panel

- Clean the Wheels and Tracks Dust, dirt, and debris can accumulate over time, leading to rolling issues. Regularly clean the wheels and the track with a damp cloth to remove any obstructions.

- Regularly checking and adjusting your screen door rollers can save you from the frustration of a stuck or difficult-to-use screen door. It's a simple DIY task that requires minimal tools and can significantly extend the lifespan of your screen door. Remember, maintaining your home's components not only keeps them functional but also adds to their aesthetic appeal and value. So, the next time you notice your screen door isn't rolling as smoothly as it used to, you'll know exactly what to do.

large metal door handles.

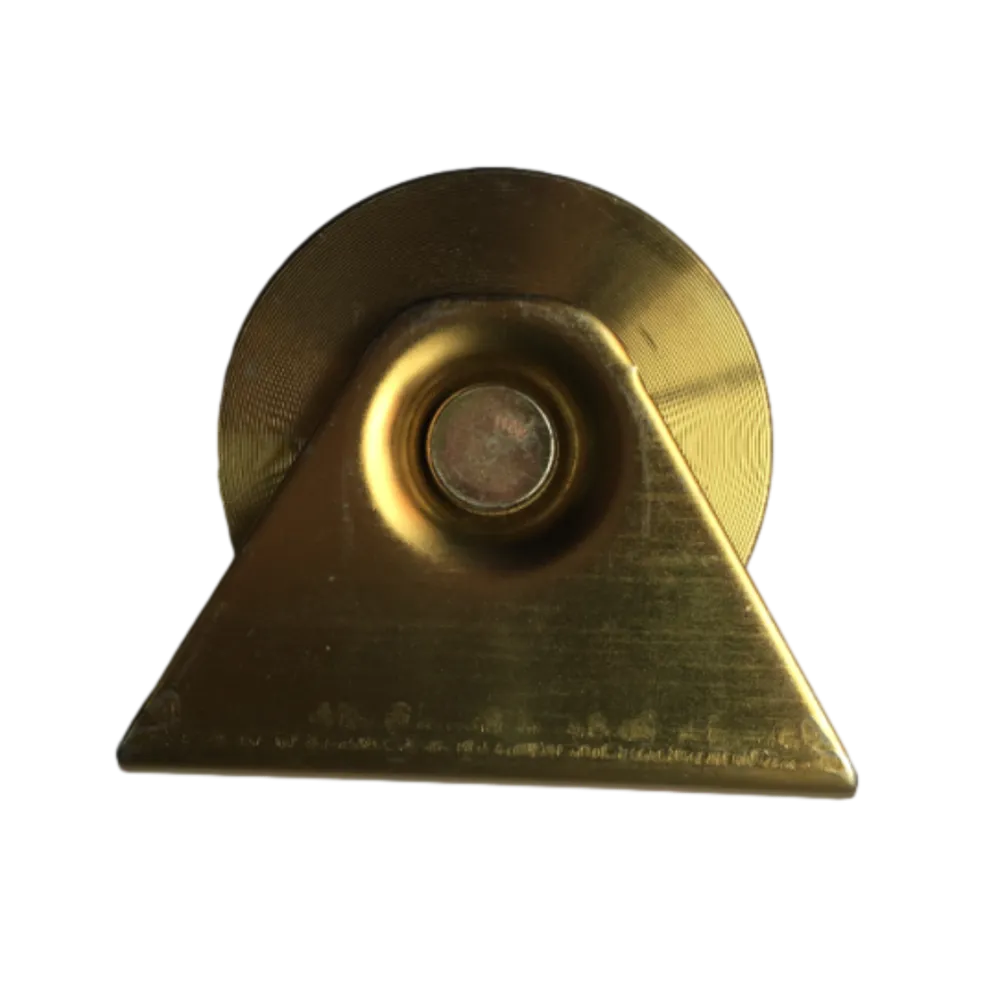

sliding cabinet roller. Made from high-quality materials such as steel or plastic, they are designed to withstand heavy use and last for many years. With proper care and maintenance, you can enjoy trouble-free performance for years to come.

sliding cabinet roller. Made from high-quality materials such as steel or plastic, they are designed to withstand heavy use and last for many years. With proper care and maintenance, you can enjoy trouble-free performance for years to come.As such, it makes the material hardy and thus can withstand different harsh environmental and mechanical conditions.

Ideally, the more the pressure, the greater the extrusion it can produce. The machine applies the initial pressure crushing the billet against the die.

At the forefront of any storage solution is its ability to keep valuables safe. Metal storage lock boxes greatly enhance security through their robust construction. Made from durable materials such as galvanized steel or aluminum, these boxes are resistant to rust, impact, and tampering. The addition of a lock hasp further elevates security by enabling the use of a padlock, allowing users to select a locking mechanism that best fits their security needs. Whether it’s for storing important documents, tools, or valuable collectibles, the metal storage lock box offers peace of mind with its strong security features.

The Significance of Metal Leaves in Welding An Art and Science Fusion

Aluminum vs Wrought Iron Fence: What are the Differences and Which is Better?

Modern Applications

Additionally, rollers can be made from different materials, including nylon, metal, and composite materials. Nylon rollers are popular due to their quiet operation and resistance to corrosion. Metal rollers, on the other hand, provide increased durability, making them ideal for heavier windows.

rollers for aluminum sliding windows

The benefits of using cast iron for spears lie in its inherent properties. Cast iron, known for its excellent castability, is resilient and suitable for manufacturing sharp, sturdy spearheads that can withstand the rigors of battle. The material's high carbon content contributes to its hardness, allowing for effective penetration without easily blunting. Moreover, the casting process enables the creation of complex shapes that traditional methods cannot replicate, leading to innovative spear designs tailored for specific combat contexts.

cast iron spear

Metal can withstand some of the most punishing weather conditions and general wear and tear that fence owners can expect to face.

In an increasingly uncertain world, the need for secure storage solutions is more relevant than ever. One of the most reliable options available today is the metal storage lock box equipped with a lock hasp. These lock boxes are designed not only for security but also for versatility, making them suitable for a variety of applications—both personal and commercial.

3. Pickets

In addition to their security and durability, stainless steel gate lock boxes are also very easy to install and maintain. These boxes are designed to fit neatly onto most gates, providing a seamless and professional appearance. Once installed, they require very little maintenance, giving you hassle-free security for your property.

Preparing for Iron Fence Installation

Aluminum windows and doors are presently used in a wide range of commercial, industrial, and residential structural products.

The process of welding metal leaves requires a high level of precision and skill. Due to their thinness, they can easily distort or burn through under intense heat, making the welding process a delicate balancing act between power and control. TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, with their ability to provide precise control over the heat source, are commonly employed for such tasks. The use of protective gases helps to prevent oxidation and maintain the integrity of the metal leaves during the process.

metal leaves for welding

But don’t underestimate the enduring charm of a well-maintained wrought iron fence. True, it needs more frequent checks for rust and occasional repainting.