...

2025-08-14 19:26

2386

...

2025-08-14 18:07

2542

...

2025-08-14 18:03

161

...

2025-08-14 18:01

925

...

2025-08-14 17:58

2232

...

2025-08-14 17:57

1100

...

2025-08-14 17:56

2174

...

2025-08-14 17:51

2645

In addition to its advanced manufacturing processes, c1 77891 factory also focuses on sustainability and environmental responsibility

...

2025-08-14 17:33

59

...

2025-08-14 17:28

2757

Diving deeper, a control box comprises several critical components, each with a specific function. Here’s a breakdown:

pvc tape for electrical insulation. Its ability to adhere to a wide range of surfaces makes it a versatile tool for various tasks. Whether you need to secure a cable bundle, create a waterproof seal, or mark equipment for identification, PVC tape is an effective solution.

pvc tape for electrical insulation. Its ability to adhere to a wide range of surfaces makes it a versatile tool for various tasks. Whether you need to secure a cable bundle, create a waterproof seal, or mark equipment for identification, PVC tape is an effective solution.

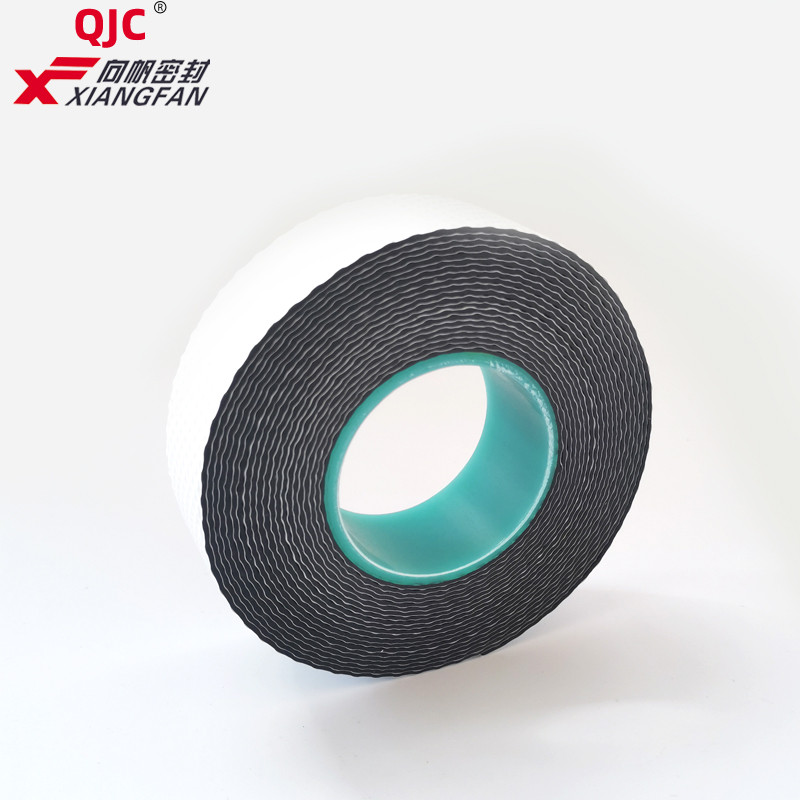

self fusing rubber tape. Once applied, it can withstand years of wear and tear without losing its adhesive properties. This makes it a cost-effective solution for long-lasting repairs and installations.

The design of a control box is a thoughtful process, taking into consideration various factors that affect its performance:

It’s a question we’ve all asked ourselves at one point or another – can electrical tape catch fire?

black cloth tape automotive.

Pure acrylics have a lower tack (“stickyness when dry” for the layman) and less adhesion on hard-to-bond plastics such as high- and low-density polyethylene (HDPE & LDPE) and polypropylene (PP) than modified acrylic or rubber adhesives. Pure acrylic adhesives are mainly used on tapes whose applications are bonding, sealing or surface protection.