best quality titanium dioxide supplier

Overall, buff percentage is a critical factor that manufacturers of titanium dioxide must carefully manage to ensure the quality, consistency, and cost-effectiveness of their products. By investing in advanced technology and processes to control buff percentage, manufacturers can meet the specific requirements of their customers and maintain a competitive edge in the market. As the demand for titanium dioxide continues to grow across various industries, manufacturers must continue to innovate and improve their processes to meet the evolving needs of their customers.

Studies have shown that TiO2 nanoparticles can cause cytotoxicity, genotoxicity, and oxidative stress in various cell types, including human lung cells and immune cells. These findings have led to calls for more research into the potential risks of TiO2 in water supplies and the development of guidelines for safe exposure levels.

China's Leading Lithopone B311 Manufacturers A Comprehensive Guide

A few processes are used to produce TiO2 pigment. Rutile TiO2 is found in nature. This is because the rutile crystal structure is the thermodynamically stable form of titanium dioxide. In chemical processes natural TiO2 can be purified, thus obtaining synthetic TiO2. The pigment can be made from ores, rich in titanium, that are mined from the earth.

Two chemical routes are used to make both rutile and anatase TiO2 pigments.

...

2025-08-14 23:55

2268

However, handling TiO2 in coatings factories requires caution due to its dust-forming nature. Strict safety measures are implemented to protect workers from respiratory hazards and ensure a controlled production environment. Advanced equipment and technologies are employed to minimize dust emissions and optimize the dispersion of the pigment in the coating.

...

2025-08-14 23:49

1725

Manufacturing Process of Lithopone 28B301 and 30B311

...

2025-08-14 22:48

649

Well asides from making you re-think that M & M addiction (chocolate coated in Titanium Dioxide…..anyone?!)

...

2025-08-14 22:41

2049

When manufacturers add titanium dioxide to foods and other ingestible products, it’s typically referred to as E171, which relates to food-grade purity.

...

2025-08-14 22:39

53

However, handling TiO2 in coatings factories requires caution due to its dust-forming nature. Strict safety measures are implemented to protect workers from respiratory hazards and ensure a controlled production environment. Advanced equipment and technologies are employed to minimize dust emissions and optimize the dispersion of the pigment in the coating.

Manufacturing Process of Lithopone 28B301 and 30B311

Well asides from making you re-think that M & M addiction (chocolate coated in Titanium Dioxide…..anyone?!)

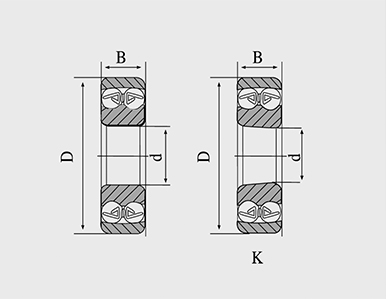

Moreover, it prevents the bearing from seizing or overheating, which can lead to catastrophic failure Moreover, it prevents the bearing from seizing or overheating, which can lead to catastrophic failure

Moreover, it prevents the bearing from seizing or overheating, which can lead to catastrophic failure Moreover, it prevents the bearing from seizing or overheating, which can lead to catastrophic failure

Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation

Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation