rutile definition suppliers

Particle Size and Shape

In a study published in the journal Food and Chemical Toxicology in 2016, researchers investigated whether titanium dioxide exposure led to an increase in colorectal tumor creation in mice by using a colitis associated cancer model. By measuring tumor progression markers, the researchers found that mice given titanium dioxide experienced enhanced tumor formation in the distal colon. There was also a decrease of cells that act as a protective barrier in the colon. The researchers wrote: “These results suggest that E171 could worsen pre-existent intestinal diseases.”

...

2025-08-16 16:53

2381

...

2025-08-16 16:48

907

How does Titanium Dioxide Work?

...

2025-08-16 15:56

1631

Most notably, a European Food Safety Authority safety assessment published in May 2021 pointed to genotoxicity concerns, as suggested by previous research. Genotoxicity is the ability of chemicals to damage genetic information such as DNA, which may lead to cancer.

...

2025-08-16 15:41

1466

Furthermore, titanium dioxide’s photocatalytic properties have led to its use in environmental applications

...

2025-08-16 15:25

945

However, China's dominance in rutile titanium dioxide manufacturing is not without challenges

...

2025-08-16 15:21

2132

How does Titanium Dioxide Work?

Most notably, a European Food Safety Authority safety assessment published in May 2021 pointed to genotoxicity concerns, as suggested by previous research. Genotoxicity is the ability of chemicals to damage genetic information such as DNA, which may lead to cancer.

Furthermore, titanium dioxide’s photocatalytic properties have led to its use in environmental applications

However, China's dominance in rutile titanium dioxide manufacturing is not without challenges

It has an extremely high melting point of 1 843ºC and boiling point of 2 972ºC, so occurs naturally as a solid, and, even in its particle form, it is insoluble in water. TiO2 is also an insulator.

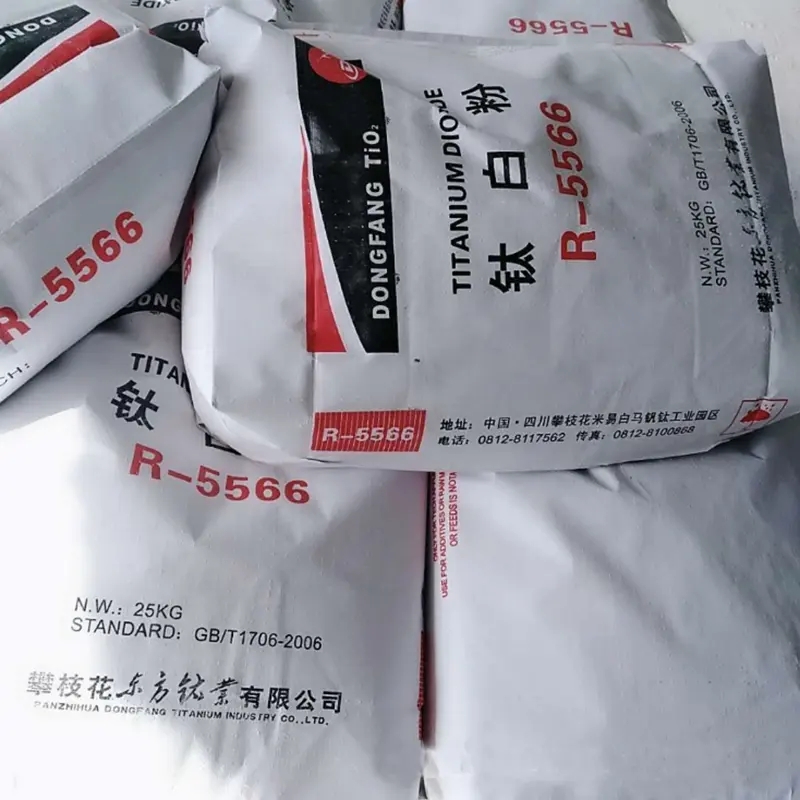

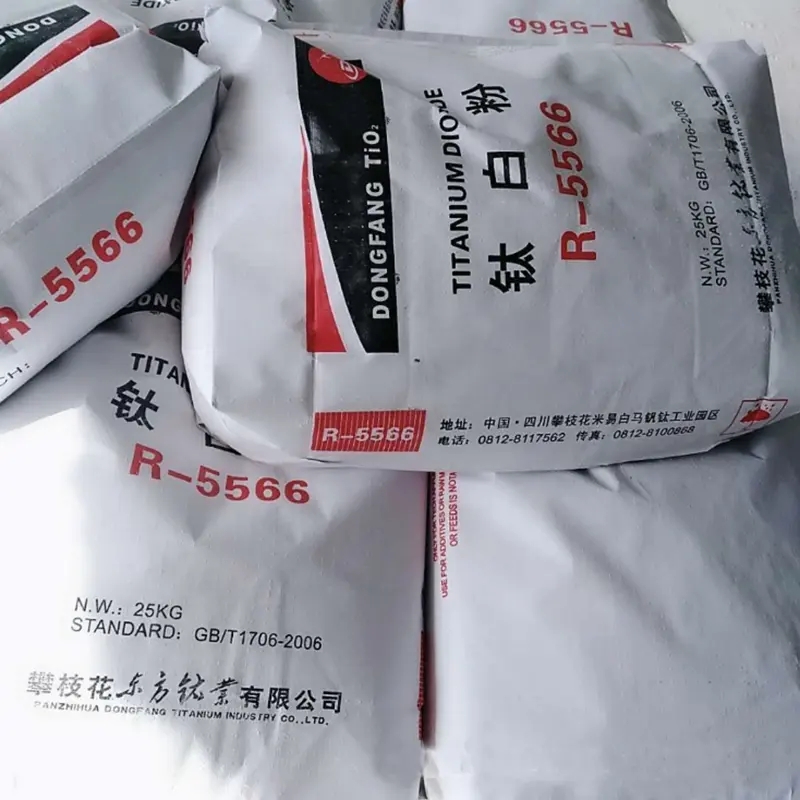

Each batch undergoes rigorous testing to ensure consistent particle size distribution, dissolution rate, and overall performance Each batch undergoes rigorous testing to ensure consistent particle size distribution, dissolution rate, and overall performance

Each batch undergoes rigorous testing to ensure consistent particle size distribution, dissolution rate, and overall performance Each batch undergoes rigorous testing to ensure consistent particle size distribution, dissolution rate, and overall performance dissolving titanium dioxide manufacturer. Advanced equipment like high-speed mixers, classifiers, and surface treatment facilities are utilized to maintain the highest standards.

dissolving titanium dioxide manufacturer. Advanced equipment like high-speed mixers, classifiers, and surface treatment facilities are utilized to maintain the highest standards.