- Non-ionic

- In the pharmaceutical industry, HPMC is commonly used as a thickener, binder, and film-forming agent in tablet formulations. Its film-forming ability allows for the creation of coatings that control drug release rates, protect the drug from moisture and light, and mask unpleasant tastes. HPMC is also used in ophthalmic preparations, where its high viscosity helps to retain the drug in the eye for extended periods of time.

Applications of HPMC

2. Food Industry In the food sector, HPMC 4000 serves as a thickener and stabilizer in sauces, dressings, and baked goods. Its ability to retain moisture and improve texture contributes to enhanced consumer satisfaction.

Additionally, HPMC's ability to form foams and gels makes it an attractive option for creating low-calorie alternatives to foods. With the rising demand for healthier food options, the application of HPMC in reformulating traditional recipes has gained significant traction in recent years.

- Relatively straightforward

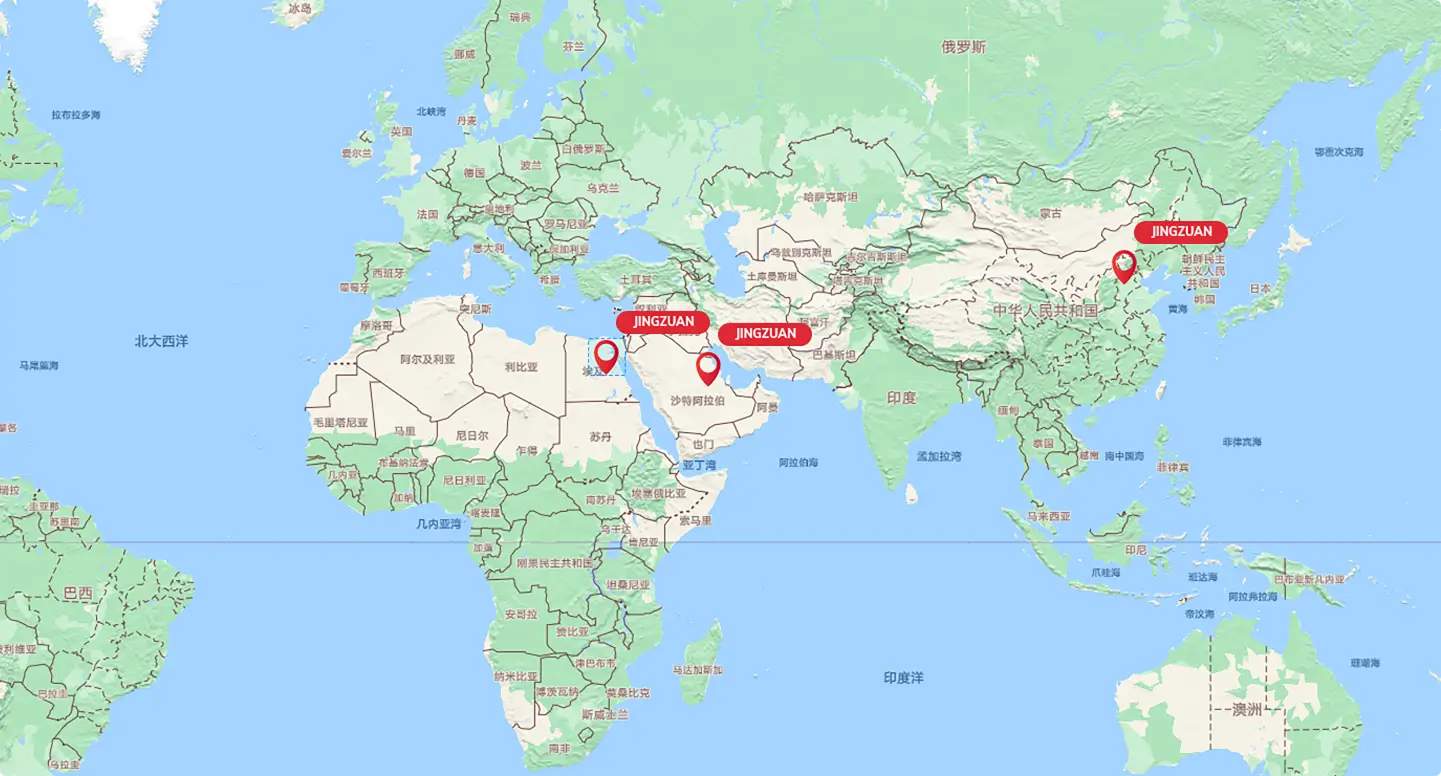

China has become a prominent player in the global HPMC market, owing to its advanced chemical processing technologies and ample raw material availability. Many manufacturers in China produce HPMC through a controlled reaction process involving alkali treatment, etherification, and purification. The production quality is regulated to ensure that the HPMC meets international standards, making it competitive in both domestic and global markets.

- HPMC manufacturers are also committed to sustainability and environmental responsibility. They adhere to strict environmental regulations and implement eco-friendly practices in their manufacturing processes. By using renewable and biodegradable raw materials, they minimize the environmental impact of their operations.

2. Food Industry HPMC's water solubility makes it a popular additive in the food industry, where it is used as a thickener, emulsifier, and stabilizer. It helps improve texture and shelf-life in various products, including sauces, dressings, and dairy items.

In conclusion, High-Performance Computing is set to redefine the standards of medical care. By enhancing diagnostic accuracy, personalizing treatment strategies, streamlining clinical trials, and optimizing epidemic responses, HPMC represents a transformative leap forward in the quest for improved patient outcomes and more effective healthcare delivery. Embracing this potential will require collaboration between technologists, healthcare providers, and policymakers to ensure that the advancements of HPC benefit all.

Exploring Hydroxyethyl Cellulose Applications and Benefits

Conclusion

Links to FDA Code of Federal Regulations for Cellulose and modified cellulose polymers

1. Low Viscosity Low viscosity HPMC usually ranges from 1000 to 6000 mPa.s. These grades are typically used when a thinner consistency is required, such as in liquid formulations or low-viscosity pastes. They offer excellent spreadability and are often used in applications where high dilution is necessary.

hpmc viscosity grades

5. Global Economic Conditions Economic factors, such as inflation rates, currency fluctuations, and trade policies, can also play a role in pricing. For instance, tariffs on imported raw materials can increase costs for manufacturers, prompting them to pass on these expenses to consumers.

2. Cosmetics and Personal Care In cosmetics, HEC serves as a thickener and emulsifier, providing the desired texture and stability to lotions, creams, and shampoos. The ability to control viscosity improves product performance and user experience.

Understanding VAE and RDP A Comprehensive Overview

1. Concentration As previously mentioned, increasing the concentration of HPMC can lead to gel formation instead of solubility. This property is harnessed in applications where viscosity is required, such as in thickeners and stabilizers.

hydroxypropyl methyl cellulose solubility

1. Pharmaceuticals In the pharmaceutical industry, hydroxyethyl cellulose is used as a binding agent in tablet manufacturing and as a suspending agent in liquid formulations. Its low toxicity and biocompatibility make it a safe choice for various applications, including ophthalmic solutions.

- Medium Viscosity HPMC Grades such as HPMC 50 and HPMC 75 offer moderate viscosity and are versatile in application. They are commonly used in cosmetic formulations, providing a smooth texture and good spreadability, while also acting as a stabilizer.

- Quality and Specification Always request product specifications and safety data sheets (SDS) to ensure you are getting a high-quality product that meets your needs.

In recent years, the demand for sustainable and safe materials has led to growing interest in natural compounds, particularly cellulose. Cellulose, a biopolymer derived from plant cell walls, is the most abundant organic polymer on Earth and plays a critical role in various industries. One of its notable derivatives is Hydroxypropyl Methylcellulose (HPMC), a modified cellulose that finds extensive applications in pharmaceuticals, food, and construction.

In conclusion, Ashland Hydroxyethyl Cellulose is a remarkable polymer that serves a multitude of functions across various industries, from personal care to food and construction. Its unique attributes and environmental benefits make it a staple ingredient for manufacturers aiming to enhance product quality and performance while meeting the growing consumer demand for sustainable solutions.

The construction industry has embraced HPMC for its performance-enhancing properties in cementitious materials. It is an essential ingredient in tile adhesives, plasters, and renderings, where it acts as a water-retaining agent. By improving workability and extending open time, HPMC makes it easier for construction professionals to apply materials without compromising adhesion or setting times. Its ability to enhance the flow and consistency of construction materials results in stronger, more durable applications.

Embracing HPMC: A Pathway to Sustainable Innovation

1. Thin-set Mortars In tile installation, HPMC is widely used in thin-set mortars due to its excellent adhesion and water retention properties. It helps ensure that tiles remain securely in place even in high-moisture environments.

2. Medium Viscosity Grades With viscosities ranging from 3000 to 10000 mPas, these HPMC grades provide a balance between water retention and workability. They are often used in pharmaceutical formulations, such as tablets and capsules, due to their ability to control the release of active ingredients.

hpmc grades pdf

Understanding HPMC Density Significance and Applications

China has positioned itself as a major supplier in the HPMC market, leveraging its manufacturing capabilities and cost-effectiveness. With advancements in production technology and strict quality control measures, Chinese manufacturers have successfully catered to both domestic and international markets. They comply with global standards, ensuring that the products meet stringent regulatory requirements.

What is HPMC Made From?

Redispersible powder polymers (RDPs) are innovative materials that have gained significant traction in various industries, particularly in construction and coatings. These fine, water-soluble powders are derived from emulsions through a drying process that maintains the functional properties of the original polymer. RDPs offer a range of benefits, making them essential for enhancing performance and functionality in a variety of applications.

Benefits of Using HPMC Powder

china hpmc powder

The Versatile Applications of Hydroxypropyl Methylcellulose

Understanding the Grades of HPMC Implications for Pharmaceutical and Food Industries

What do HPMC veggie capsules do?

The cellulose derivatives at concentrations up to 100% were nonirritating to mildly irritating, nonsensitizing, and nonphotosensitizing when evaluated in clinical studies. The CIR Expert Panel concluded that Cellulose, Calcium Carboxymethyl Cellulose, Carboxymethyl Cellulose Acetate Butyrate, Carboxymethyl Hydroxyethylcellulose, Cellulose Acetate, Cellulose Acetate Butyrate, Cellulose Gum, Cellulose Acetate Propionate, Cellulose Acetate Propionate Carboxylate, Cellulose Succinate, Cetyl Hydroxyethylcellulose, Ethylcellulose, Hydrolyzed Cellulose Gum, Hydroxybutyl Methylcellulose, Hydroxyethylcellulose, Hydroxyethyl Ethylcellulose, Hydroxypropylcellulose, Hydroxypropyl Methylcellulose, Methylcellulose, Hydroxypropyl Methylcellulose Acetate/Succinate, Methylcellulose, Methyl Ethylcellulose, Methyl Hydroxyethylcellulose, Microcrystalline Cellulose, Potassium Cellulose Succinate and Sodium Cellulose Sulfate were safe for use as cosmetic ingredients.

The applications of HPMC powder are extensive and varied. In the construction industry, HPMC is widely used as an additive in cement-based products such as tile adhesives, grouts, and mortars. Its water-retention properties improve workability and performance, ensuring that mixtures remain workable for longer periods while enhancing adhesion to surfaces.

hydroxypropyl methylcellulose powder

Applications in Pharmaceuticals

5. Global Economic Conditions Economic factors, such as inflation rates, currency fluctuations, and trade policies, can also play a role in pricing. For instance, tariffs on imported raw materials can increase costs for manufacturers, prompting them to pass on these expenses to consumers.

Properties of Hydroxypropyl Methylcellulose