Heavy-duty sewing and embroidery machines represent a blend of strength, efficiency, and versatility. Whether you are a seasoned professional, a hobbyist, or just starting your sewing journey, the right heavy-duty machine can elevate your work and inspire creativity. By carefully considering your project needs and the features of different machines, you can choose the perfect companion for all your sewing and embroidery endeavors. Embrace the possibilities that await with a reliable heavy-duty machine, and watch your crafts reach new heights!

Despite their numerous advantages, the adoption of CNC stitching machines comes with certain challenges. Initial investment costs for advanced CNC equipment can be significant, particularly for small to medium-sized enterprises. Additionally, the shift from manual to automated processes requires workforce training and a change in operational dynamics. Nevertheless, the long-term benefits, including increased efficiency, reduced errors, and lower operational costs, often outweigh these challenges.

Overall, the 2% needle industrial sewing machine is a valuable tool for businesses in the textile industry. Its speed, precision, and versatility make it a reliable choice for a wide range of sewing tasks. Whether you are sewing garments, upholstery, or accessories, this machine can help you achieve professional results in a fraction of the time it would take with a traditional sewing machine.

Key Features to Look For

Canvas Products

shuttle hook case. If necessary, replace the shuttle hook case or seek professional help.

To create a double thread chain stitch, start by threading your needle with two strands of embroidery floss. Knot the end of the floss and bring the needle up from the back of the fabric to the front. Make a small loop with the floss and bring the needle back down through the fabric, catching the loop to create the first chain stitch.

3. Walking Foot For projects involving multiple layers of thick fabric, a walking foot (or presser foot) can be invaluable. This feature helps ensure that all layers feed evenly through the machine, preventing uneven stitches and fabric shifting.

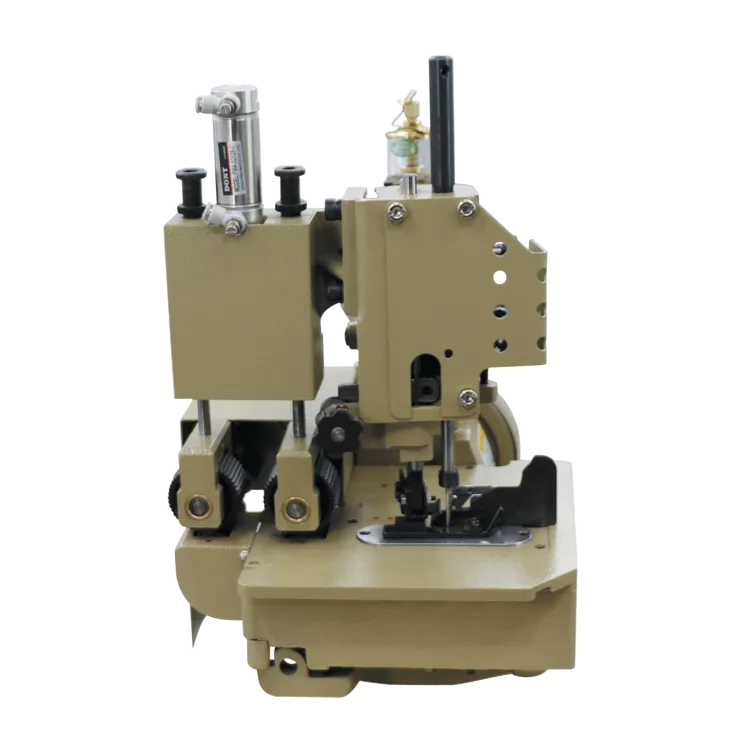

Industrial Overlockers for Sale A Comprehensive Guide

Conclusion

Conclusion

2. Adjust Tension Settings Every fabric type may require different tension settings on your overlock machine. Experiment with tension adjustments on scraps before sewing your main project to achieve the best results.

1. Strength and Durability Lock stitches are known for their robustness. The interlocking of two threads creates a seam that can withstand significant tension, making it an excellent choice for seams that experience stress.

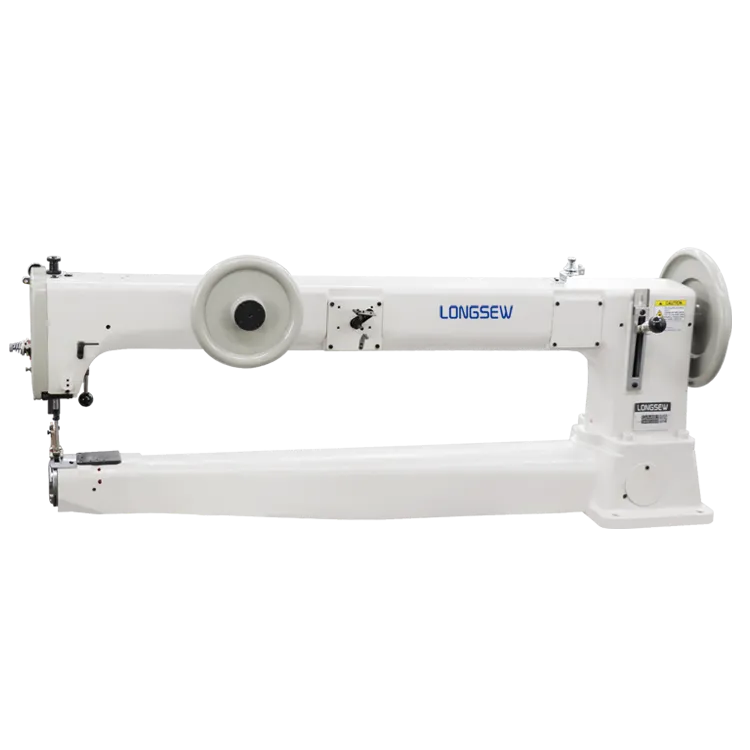

One of the key benefits of a long arm walking foot sewing machine is its versatility. Whether you are working on intricate quilting designs or simple sewing tasks, this type of machine can handle it all. Many models are equipped with multiple stitch options, allowing users to customize their projects to suit their personal style and preferences. Additionally, several machines come with built-in features such as automatic thread cutting, adjustable speed control, and stitch length adjustments, making the sewing process not only smoother but also more enjoyable.

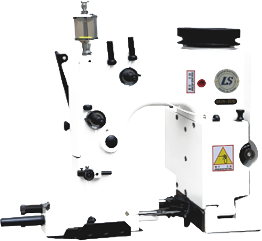

long arm walking foot sewing machine for sale

The Unique Challenges of Sewing Fur and Leather

One of the primary advantages of using a zigzag sewing machine is its ability to finish seams neatly. The zigzag stitch can prevent fabric from fraying, ensuring durability and longevity in garments or crafts. This is particularly useful for sewing with knit or stretch fabrics, where additional flexibility is required. The machine’s ability to create elastic stitches means that it can accommodate the natural movement of the fabric, leading to comfortable and well-fitted garments.

sewing zig zag machine

Where to Find the Best Deals

A baffle sewing machine is specifically designed to create baffles in various types of materials, which are essential for products like sleeping bags, jackets, and comforters. The term baffle refers to the construction technique that involves dividing a material into compartments, which helps to optimize insulation and create a structured shape. Traditional sewing machines do not possess the capability or efficiency to handle such specialized tasks, leading to the development of the baffle sewing machine.

A compound feed heavy duty sewing machine is equipped with a unique feeding mechanism that combines different feed types needle feed, walking foot, and presser foot. This combination allows the machine to pull the fabric evenly from both the top and bottom, ensuring smooth stitching even on thick or multi-layered materials. This capability makes it ideal for sewing heavy fabrics such as leather, denim, canvas, and various synthetic materials.

The Importance of Zigzag Stitching

The Auto Cutter Sewing Machine Revolutionizing the Textile Industry

For intermediate users or those seeking more versatility, prices generally range from $400 to $1,200. These machines often boast a wider selection of stitch patterns, more embroidery options, and enhanced durability. Many also come with additional accessories like multiple presser feet and extension tables, making them an excellent choice for anyone looking to expand their sewing capabilities.

fully automatic sewing machine price

The versatility of the 2% needle walking foot sewing machine is further reflected in its wide array of applications. Beyond quilting, it is suited for sewing bags, upholstery, and even leather. This adaptability makes it a favorite among fashion designers and DIY enthusiasts who frequently switch between different materials. Whether you’re connecting heavy denim for jeans or soft chiffon for a flowing dress, this machine can handle it all with ease.

Understanding the Lockstitch Sewing Machine A Vital Tool in Textile Production

1. Efficiency These machines are designed for performance, which allows for faster project completion. Saving time does not only increase productivity but also offers opportunities for more creative projects.

Heavy duty basic sewing machines find their place in various applications. They are popular among quilters who require precision and strength in stitching multiple layers of fabric. Fashion designers also benefit from the capabilities of these machines when working with denim and other tough textiles. Moreover, hobbyists and DIY enthusiasts can bring their creative visions to life with the reliability of a heavy duty machine, making everything from custom clothing to durable bags and accessories.

When looking for an industrial machine for sewing leather, there are a few key features to consider. The first is the type of needle system the machine uses. Leather requires a specific needle type, such as a wedge point needle, that can penetrate through the material without causing damage or distortion.

%20(200%20%C3%97%20200%20px)%20(2)%20(1).webp)

The high-speed single needle lockstitch sewing machine operates using a simple yet effective mechanism. It utilizes a single needle that passes through the fabric layers, forming a lockstitch by interlocking the upper thread with the lower thread supplied from the bobbin. This design not only ensures durability and strength in the seams but also allows for a wide range of stitches, from basic straight stitches to more complex patterns.