coating raw material

China's Titanium Dioxide Industry A Pillar of Modern Industrial Development

Maintaining consistency and quality during scale-up is one of the most challenging aspects of nano-TiO2 production. The factory must adhere to stringent quality control measures, using advanced analytical techniques like X-ray diffraction (XRD) and transmission electron microscopy (TEM) to ensure the purity and uniformity of the nanoparticles. Additionally, environmental safety and health considerations are paramount, given the potential risks associated with nanomaterials.

Titanium dioxide as used in sunscreens is commonly modified with other ingredients to ensure efficacy and stability. Examples of what are known as surface modifier ingredients used for titanium dioxide include stearic acid, isostearic acid, polyhydroxystearic acid, and dimethicone/methicone copolymer.

In conclusion, anatase titanium dioxide plays a crucial role in the coatings industry, offering a wide range of benefits to manufacturers. Its UV resistance, thermal stability, aesthetic properties, durability, and ease of use make it a versatile and reliable ingredient for various types of coatings. With its cost-effectiveness and performance advantages, anatase titanium dioxide continues to be a preferred choice for coatings manufacturers worldwide.

Furthermore, titanium dioxide is known for its excellent light stability and resistance to fading, making it an ideal choice for archival or long-term storage papers. By incorporating titanium dioxide into the paper formulation, manufacturers can ensure that the paper remains bright and white over time, even when exposed to sunlight or harsh environmental conditions.

...

2025-08-15 01:06

2837

Some of the leading players in the rutile market factory industry include Rio Tinto, Iluka Resources, Tronox, and Cristal Global. These companies have extensive experience in the extraction, processing, and marketing of rutile, and they continue to invest in research and development to improve their processes and products.

...

2025-08-15 00:52

723

Australia and New Zealand review of TiO2

...

2025-08-15 00:14

790

In addition to its mechanical benefits, titanium dioxide also exhibits photocatalytic properties titanium dioxide dissolved in oil factories. When dissolved in oil, it can act as a self-cleaning agent, breaking down organic impurities and pollutants on contact with sunlight. This can be particularly advantageous in reducing the environmental impact of oil spills or leaks, as TiO2 can aid in the degradation of hydrocarbons.

titanium dioxide dissolved in oil factories. When dissolved in oil, it can act as a self-cleaning agent, breaking down organic impurities and pollutants on contact with sunlight. This can be particularly advantageous in reducing the environmental impact of oil spills or leaks, as TiO2 can aid in the degradation of hydrocarbons.

...

2025-08-14 23:55

1966

Some of the leading players in the rutile market factory industry include Rio Tinto, Iluka Resources, Tronox, and Cristal Global. These companies have extensive experience in the extraction, processing, and marketing of rutile, and they continue to invest in research and development to improve their processes and products.

Australia and New Zealand review of TiO2

In addition to its mechanical benefits, titanium dioxide also exhibits photocatalytic properties titanium dioxide dissolved in oil factories. When dissolved in oil, it can act as a self-cleaning agent, breaking down organic impurities and pollutants on contact with sunlight. This can be particularly advantageous in reducing the environmental impact of oil spills or leaks, as TiO2 can aid in the degradation of hydrocarbons.

titanium dioxide dissolved in oil factories. When dissolved in oil, it can act as a self-cleaning agent, breaking down organic impurities and pollutants on contact with sunlight. This can be particularly advantageous in reducing the environmental impact of oil spills or leaks, as TiO2 can aid in the degradation of hydrocarbons.

Digestive System Exposure

The company has a wide variety of products, mainly including rutile titanium dioxide R818, R838, R868, R878, covering profiles, also have anatase TiO2 A1. Soft plastics and masterbatches, flat coatings, high-gloss coatings, water-based coatings, oil-based coatings, rubber, powder coatings, papermaking and other special fields, its products have been known in the market for their excellent whiteness and brightness, good hiding power and tinting power, stable application performance, and stable product quality and supply capacity.

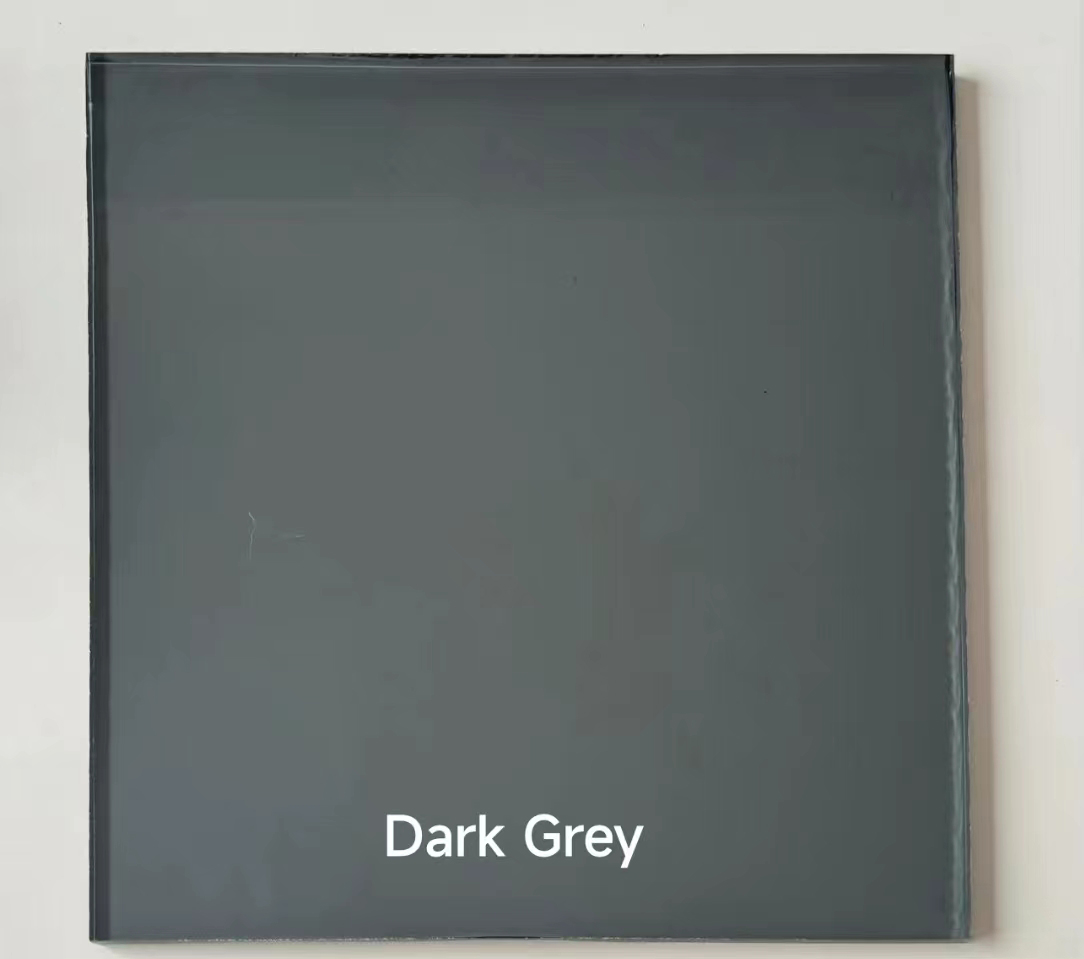

In rooms where natural light is scarce, the use of patterned glass can help diffuse and reflect light, brightening the environment and making it appear more spacious In rooms where natural light is scarce, the use of patterned glass can help diffuse and reflect light, brightening the environment and making it appear more spacious

In rooms where natural light is scarce, the use of patterned glass can help diffuse and reflect light, brightening the environment and making it appear more spacious In rooms where natural light is scarce, the use of patterned glass can help diffuse and reflect light, brightening the environment and making it appear more spacious

.

. The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room

The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room