...

2025-08-14 15:53

376

...

2025-08-14 15:39

752

...

2025-08-14 14:48

1157

...

2025-08-14 14:45

2535

...

2025-08-14 14:44

1403

...

2025-08-14 14:43

2152

One of the key advantages of Lithopone 28-30% is its low toxicity and non-carcinogenic nature

...

2025-08-14 14:41

917

...

2025-08-14 13:39

57

...

2025-08-14 13:24

1702

...

2025-08-14 13:23

1019

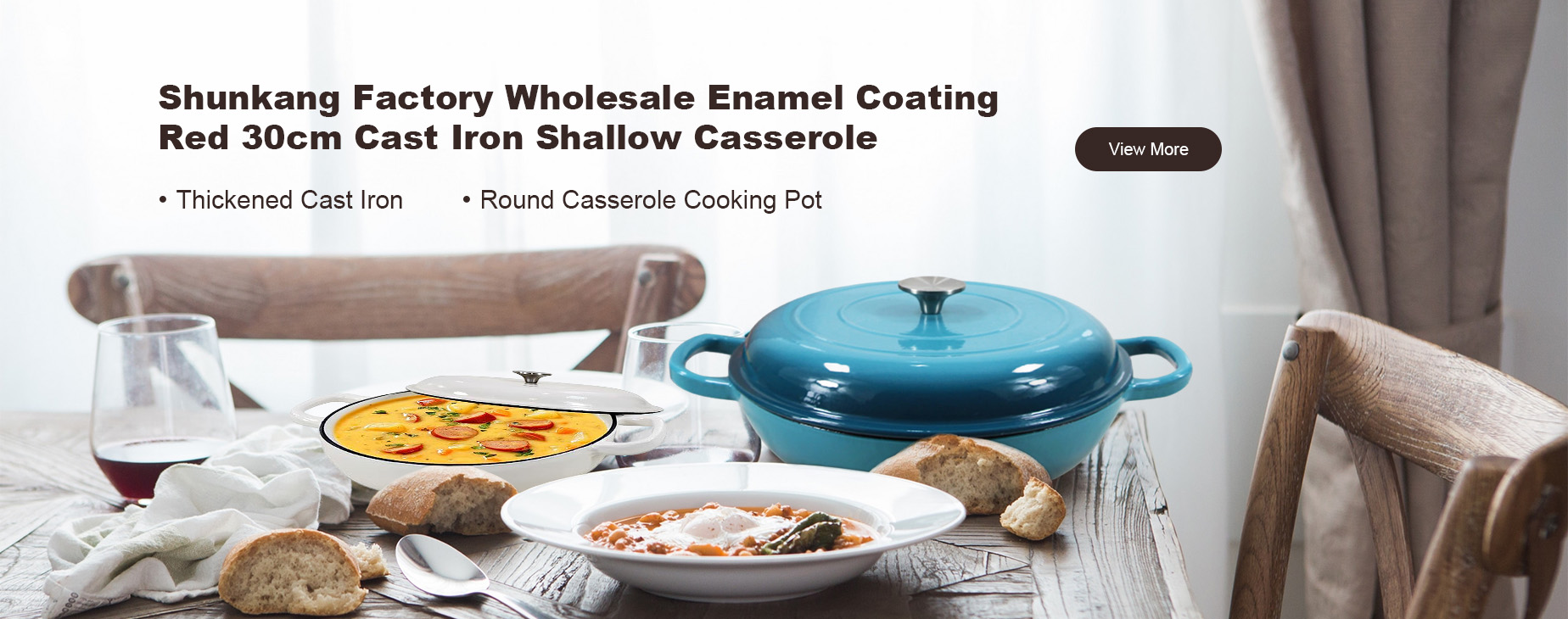

Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests

Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests Moreover, its large cooking area allows for multitasking, making it perfect for family meals or entertaining guests

The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan

The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan