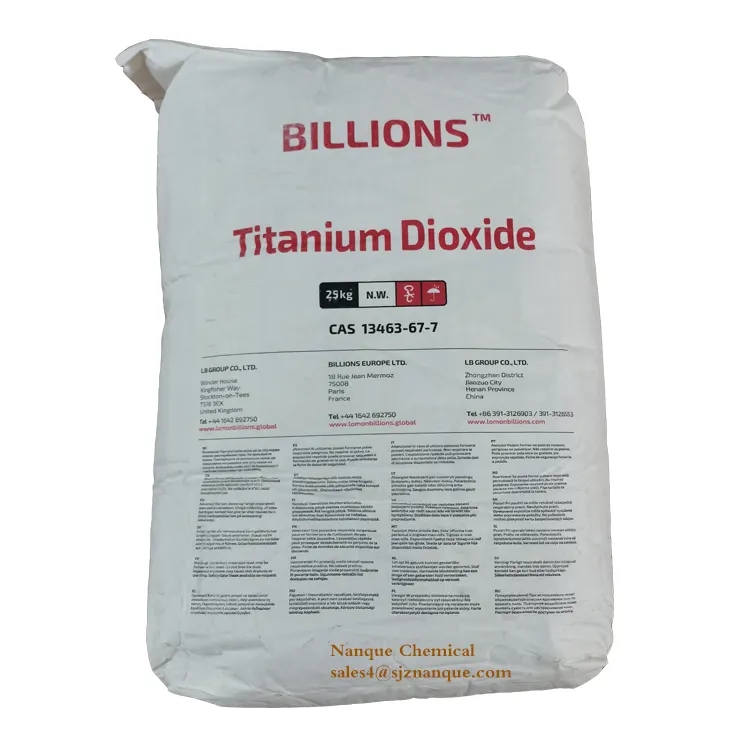

anatase tio2 manufacturers

...

2025-08-14 20:55

544

This food chemical has been used in food for more than half a century, but recent studies show it may be harmful.

...

2025-08-14 20:09

2563

Thirdly, titanium dioxide is a semiconductor material with a wide bandgap energy of 3 6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

...

2025-08-14 20:05

627

...

2025-08-14 19:42

499

Harnessing Sustainable Titanium Dioxide Production in Eco-Friendly Factories

...

2025-08-14 19:09

2917

One of the main uses of wholesale colloidal silicon dioxide is as a thickening and anti-caking agent in food and pharmaceuticals. It is commonly added to powdered substances to prevent clumping and improve flowability. In this application, colloidal silicon dioxide helps to maintain product quality and extend shelf life.

...

2025-08-14 19:08

1352

Another critical advantage of using TiO2 in pigments is its non-toxic nature. Unlike some traditional pigments that may contain heavy metals or other harmful substances, TiO2 is recognized as safe by regulatory bodies around the world. This attribute allows manufacturers to develop products that are not only visually appealing but also meet stringent health and safety requirements. As consumer awareness about health issues increases, the demand for non-toxic pigments continues to rise, further solidifying TiO2's position in the market.

...

2025-08-14 18:39

1679

Overall, r 996 titanium dioxide suppliers have established themselves as reliable and reputable sources for this essential pigment. With their high-quality products, reliable supply chain, competitive pricing, and excellent customer service, businesses can rely on these suppliers for all their r 996 titanium dioxide needs. Partnering with r 996 titanium dioxide suppliers is a smart choice for businesses looking to enhance their production processes and deliver top-quality products to their customers.

...

2025-08-14 18:36

1855

The factory utilizes sophisticated nanotechnology, allowing for the controlled synthesis of titanium dioxide particles. This method not only improves the optical and photocatalytic properties of the final product but also reduces waste and energy consumption during production. The precision engineering at Microbar ensures consistent quality and purity, making their titanium dioxide highly sought after in the global market.

...

2025-08-14 18:35

1500

...

2025-08-14 18:25

2038

...

2025-08-14 18:25

2038

In addition to quality, CL77891 also offers a wide range of titanium dioxide products to cater to different applications

%

In the field of ceramics, barium zinc sulfate is used as a crucial constituent in the production of glazes and enamels. Its ability to impart vitreous luster and enhance thermal stability ensures that the end products have superior durability and aesthetic appeal. Additionally, this compound plays a vital role in the manufacture of special types of glass, contributing to their optical clarity and mechanical strength.

In addition to quality, CL77891 also offers a wide range of titanium dioxide products to cater to different applications

%

In the field of ceramics, barium zinc sulfate is used as a crucial constituent in the production of glazes and enamels. Its ability to impart vitreous luster and enhance thermal stability ensures that the end products have superior durability and aesthetic appeal. Additionally, this compound plays a vital role in the manufacture of special types of glass, contributing to their optical clarity and mechanical strength.

- Slurry Pump

- Slurry Pump selection

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- Applications of Rubber Lined Slurry Pumps

- Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

- BCT Ceramic Slurry Pumps

- Slurry Pump

- How does a dredge pump work?

- What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

- Types of slurry pump installation.

- Lifetime use

- Vertical Slurry Pump

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

- Floor drainage

- Better safety

- Dredge Pump

- These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

- Slurry Pump Impeller

- How to choose a slurry pump?

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Natural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

- Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

- As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

- If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

- Slurry Pump

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

- Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

- Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

- >Slurry Pump

- reduce the discharge pressure of the pump to the lowest possible point, and.

- Underwater installation

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

- For pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

- - Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

- Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- Some models can generate discharge pressures up to 260 ft. (80 m).

- 600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

- For example.

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

- If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

- Heavy-Duty Slurry Pump

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

- Conveying medium