In addition to its advanced manufacturing processes, c1 77891 factory also focuses on sustainability and environmental responsibility

...

2025-08-14 14:09

1924

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality

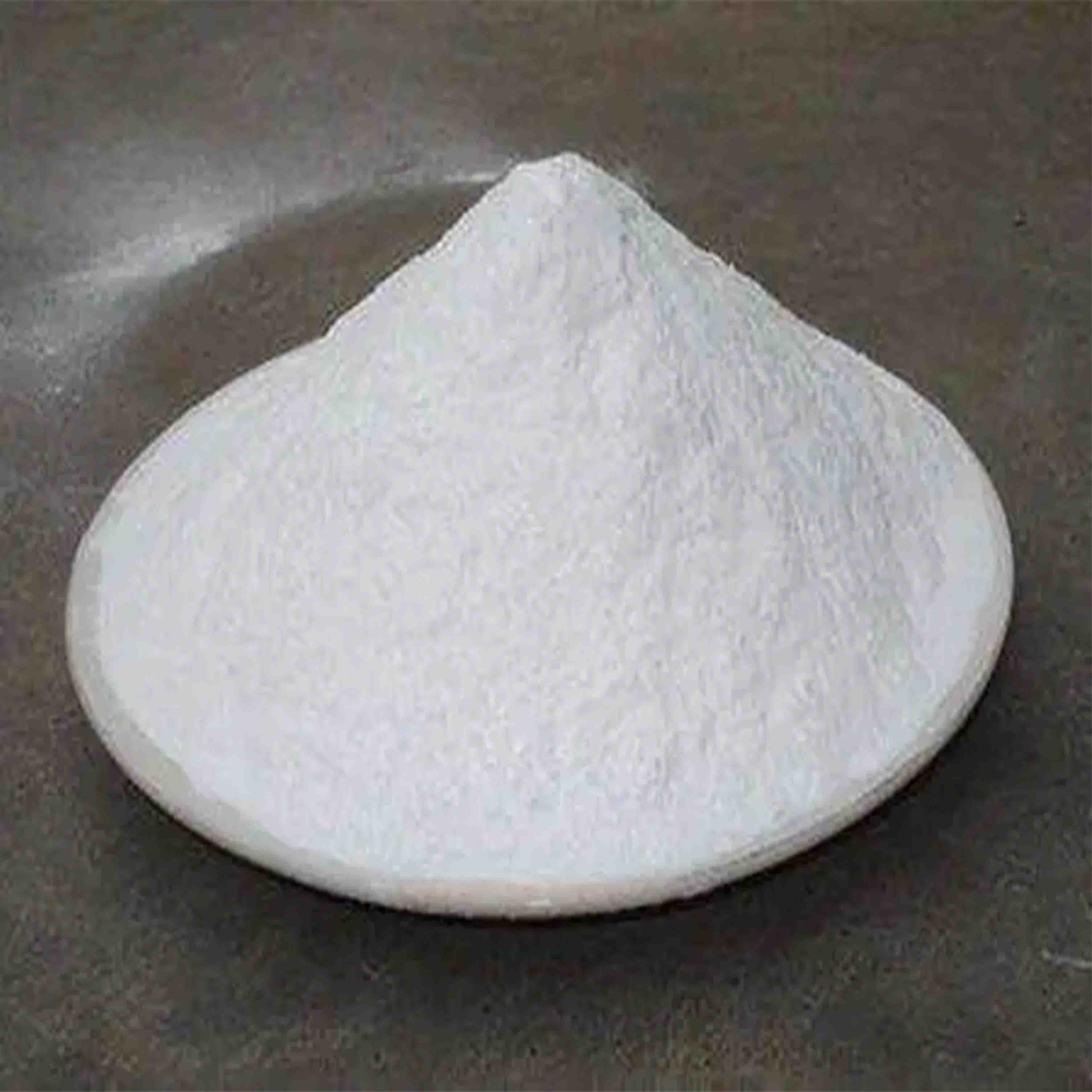

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments.

wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments.