Suppliers of titanium dioxide for coatings provide manufacturers with the raw material needed to produce high-quality coatings. These suppliers offer different grades and forms of titanium dioxide to meet the specific requirements of various coatings applications. Whether it is for architectural coatings, automotive coatings, or industrial coatings, suppliers of titanium dioxide play a critical role in ensuring that manufacturers have access to the right materials to produce coatings that meet their performance and aesthetic goals.

...

2025-08-15 04:07

2828

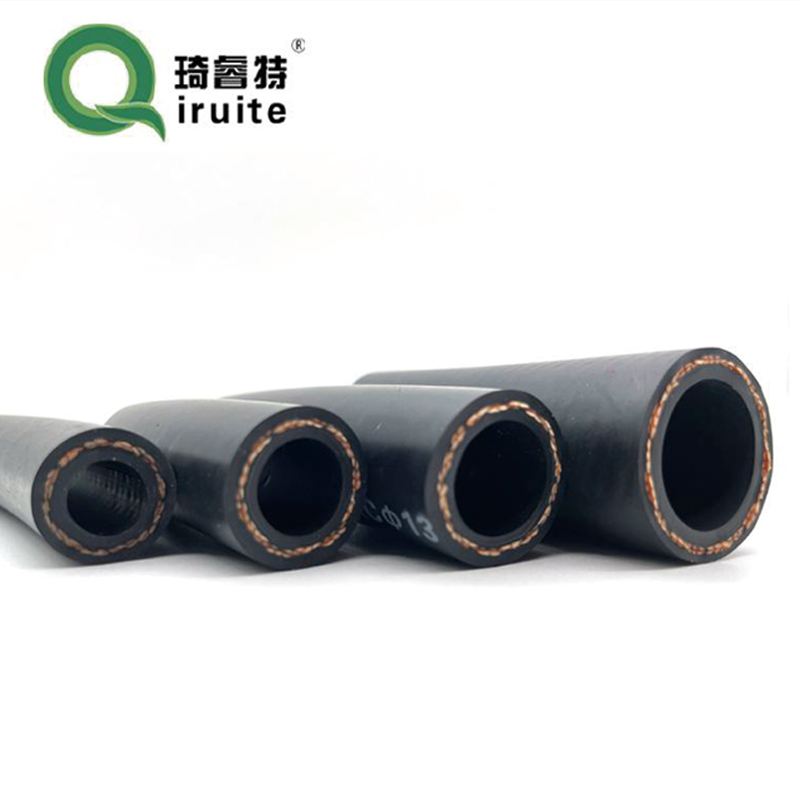

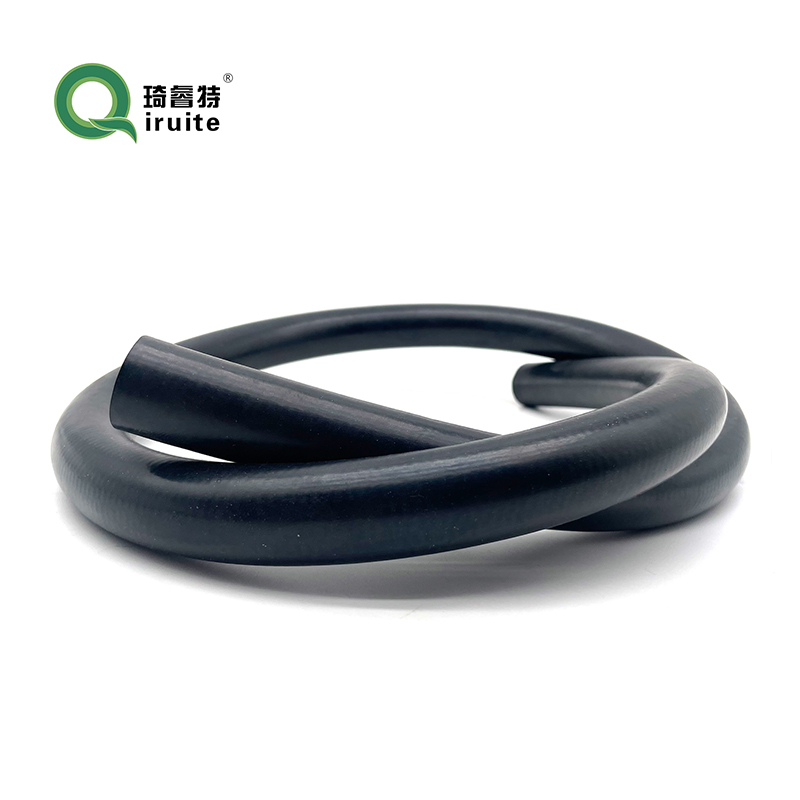

They are also designed to resist oil and chemical exposure, ensuring a long service life They are also designed to resist oil and chemical exposure, ensuring a long service life

They are also designed to resist oil and chemical exposure, ensuring a long service life They are also designed to resist oil and chemical exposure, ensuring a long service life

This can result in loss of vehicle control, leading to collisions with other vehicles or obstacles on the road This can result in loss of vehicle control, leading to collisions with other vehicles or obstacles on the road

This can result in loss of vehicle control, leading to collisions with other vehicles or obstacles on the road This can result in loss of vehicle control, leading to collisions with other vehicles or obstacles on the road