Advantages of Using a Walking Foot

The intersection of technology and craftsmanship in the leather industry is not just a trend; it reflects the ongoing evolution of manufacturing processes in response to changing consumer demands. Industrial sewing machines designed for leather are pivotal in this transformation. By combining speed, efficiency, and precision, these machines not only enhance productivity for manufacturers but also contribute to the overall quality and durability of leather products in the market. As the industry continues to innovate, it is likely that we will see further advancements in sewing technology that will continue to elevate the art of leatherwork.

1. Machine Type Determine whether you want a mechanical or computerized machine. Mechanical machines are often simpler and more straightforward, while computerized variants offer advanced features like automatic buttonholes and precise stitch selection.

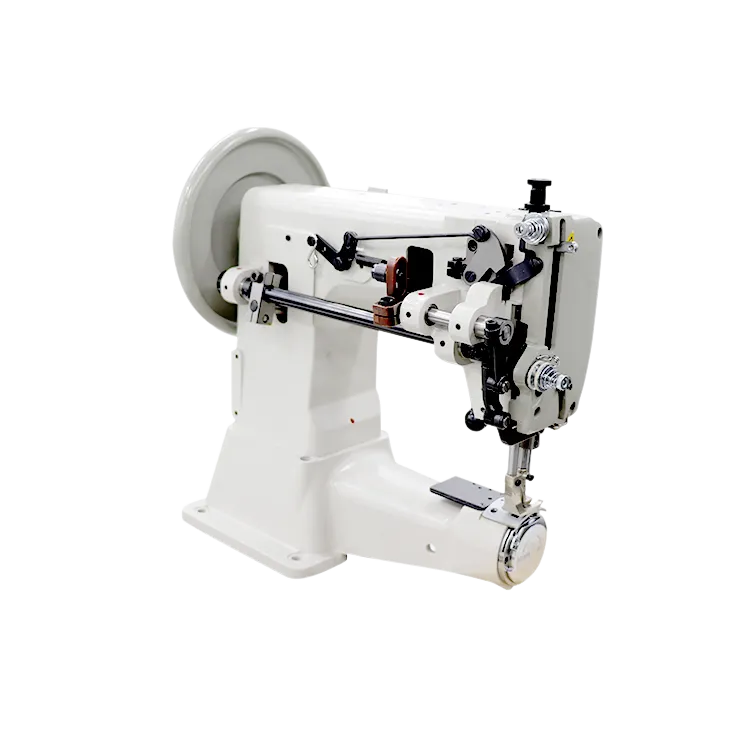

When looking for an industrial machine for sewing leather, there are a few key features to consider. The first is the type of needle system the machine uses. Leather requires a specific needle type, such as a wedge point needle, that can penetrate through the material without causing damage or distortion.

4. Metal Construction A metal frame adds durability and stability, making it easier to sew through tough materials. Plastic models might struggle with thick fabrics, leading to frustration and poor results.