In addition to our commitment to quality, we also prioritize sustainability in our manufacturing processes. We are dedicated to minimizing our environmental impact and constantly seek ways to improve our energy efficiency and reduce waste

- In conclusion, bit for rock drilling plays a crucial role in the success of drilling operations in various industries. Choosing the right bit based on rock formation and drilling conditions, as well as ensuring proper maintenance and care, are essential for achieving efficient and productive drilling operations. With continued advancements in bit technology, the future looks promising for the development of even more advanced and high-performance rock drilling bits.

- In the world of industrial piping, large diameter fiberglass pipes have become a cornerstone for their durability and adaptability. These pipes are engineered to withstand the test of time and the elements, making them an ideal choice for various demanding applications.

- A coupling sleeve, also known as a hydraulic adapter or coupling, serves as the connecting bridge between hydraulic hoses, pipes, or fittings. It is designed to facilitate secure, leak-proof connections, ensuring the smooth flow of hydraulic fluid within the system. The percentage symbol in coupling sleeve in web-based contexts is simply a URL encoding for the space character, but it underscores the importance of clear communication in technical specifications.

- When selecting a drill bit extension rod, it's crucial to consider factors such as length, material, and compatibility

cnap 711. It allows organizations to enforce security policies based on the device's security posture and user identity. For example, a device that fails the security posture assessment may be denied access to certain sensitive resources or applications, while a user who has been flagged as high-risk may be required to complete additional authentication steps before accessing the network.

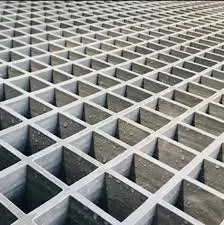

cnap 711. It allows organizations to enforce security policies based on the device's security posture and user identity. For example, a device that fails the security posture assessment may be denied access to certain sensitive resources or applications, while a user who has been flagged as high-risk may be required to complete additional authentication steps before accessing the network.The selection of the resin option also depends upon the purpose of use. For the general purposes Orthophthalic Polyester is more suitable. Some other resin options are Vinyl Ester, Isophthalic Polyester (or ISO), Fire Retardant and USDA certified. All resin options are UV Resistant and are designed for different purposes and conditions.

Available in various colors and styles, such as green, yellow, grey, orange and various other custom colors, fiberglass grating is more appealing in look as well. To ensure the longevity of the product, color is permanently added to the resin formula. The color and style of the grating are decided, while keeping the safety hazards in account. Some of the most prominent industries that use fiberglass gratings are waste water treatment plants, food processing plants, aquariums, power plants, chemical plants, lift stations, plating shops and also plants with canning and beverage facilities.

fiberglass tanks for sale. This is particularly useful in industries where temperature control is critical, such as food processing or pharmaceuticals.

fiberglass tanks for sale. This is particularly useful in industries where temperature control is critical, such as food processing or pharmaceuticals.They are FRP Blind, FRP Elbow, FRP Flange and FRP U type Fittings.