Rubber tapes are generally non-adhesive, and are either equipped with a liner or are linerless. Stretched and overlapped layers will fuse or bond together to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%. For high- and medium-voltage applications — where the electrical stresses are high (e.g. connector areas, lug areas, and cable shield cut-back areas) — tape should be stretched just short of its breaking point.

- In addition to electrical insulation, PVC tape also finds applications in cable splicing, wire harnessing, and general-purpose binding

- Rubber

Electrical tapes are typically made with a polyvinylchloride (PVC) backing and a non-corrosive rubber-based adhesive. The backing is what gives it the ability to stretch and conform to cables and wiring. This stretch is a critical characteristic of electrical tapes because it allows the tape to wrap tightly around cables for long-lasting insulation. Most cloth, film, and other types of tapes do not possess the elongation characteristics that allow electrical tapes to function properly.

Self-fusing silicone electrical tape represents a significant advancement in electrical insulation technology. Its combination of high-temperature resistance, water and chemical resilience, and self-adhering properties makes it an ideal choice for a wide array of applications. Whether for professional use in industrial settings or handy DIY repairs at home, self-fusing silicone tape provides a reliable and effective solution for protecting and insulating electrical components. As awareness of its benefits grows, it is likely that this innovative product will continue to gain popularity among electricians and gardeners alike, effectively redefining the standards for electrical insulation.

Commercial Control Boxes

In conclusion, butyl rubber tape is a versatile and effective adhesive solution that has proven its value across numerous applications. Its strong adhesive properties, waterproof and weather-resistant qualities, and flexibility make it an invaluable tool for both professionals and DIY enthusiasts. With its ease of use and longevity, it's no wonder that butyl rubber tape has become a go-to material for repairs, sealing, and construction tasks. Whether you are tackling a home improvement project or working on a commercial construction site, investing in butyl rubber tape can provide you with a reliable and efficient solution for your sealing and bonding needs.

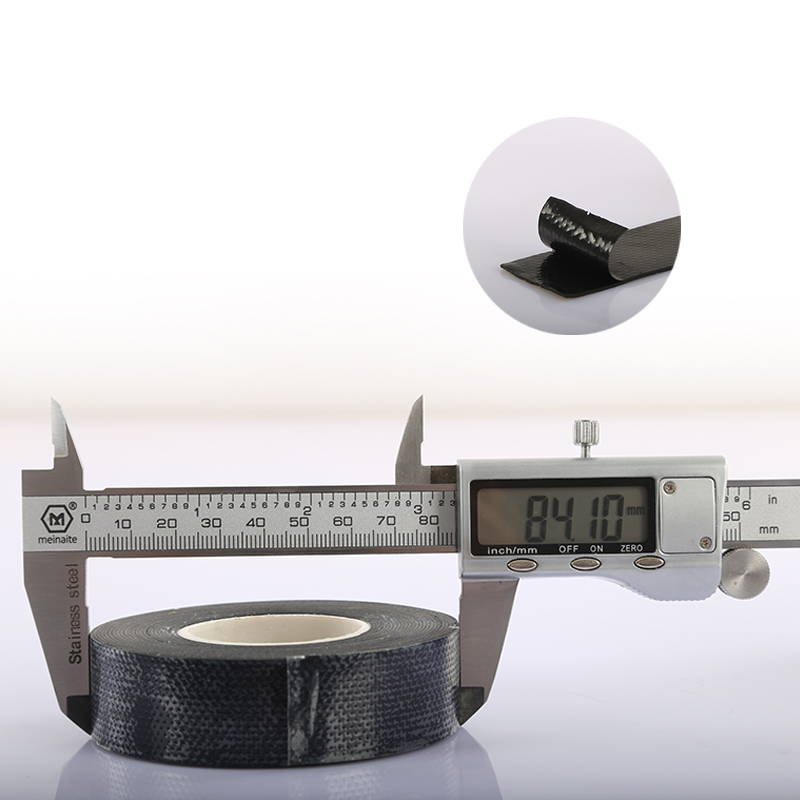

Material: Ethylene propylene rubber