lithopone paint

Hebei Caixin Material Technology Co., LTD., formerly established in 2005, is located in the core of Beijing-Tianjin-Hebei City cluster, close to Tianjin Port, the largest port in the north, with developed transportation and outstanding people. After the continuous efforts of Caiqing people, has accumulated assets for the company of nearly 200 million, nearly 1,000 employees, Caiqing technology has become the pigment titanium dioxide research and development, production, sales and import and export trade in one of the large company, we integrate industry resources, to provide personalized customized services for global customers. We adhere to the market-oriented, good faith as the principle, is committed to open up a diversified international market, for the world customers to provide quality products, efficient service, is our unremitting pursuit. We sincerely invite customers from all over the world to visit our company.

...

2025-08-16 13:50

2160

TiO2 itself was officially first named and created in a laboratory in the late 1800s. It wasn’t mass manufactured until the early 20th century, when it started to take over as a safer alternative to other white pigments.

...

2025-08-16 13:18

2345

...

2025-08-16 13:13

553

...

2025-08-16 12:55

1732

In conclusion, titanium dioxide (TiO2) is a versatile white pigment with a range of applications in various industries. Its transparency, combined with its other properties such as opacity, brightness, and durability, makes it an attractive option for manufacturers seeking to improve the appearance and functionality of their products. With ongoing research and development, the future of transparent TiO2 looks promising, with new applications and markets emerging as consumers demand more aesthetically pleasing and high-performance products.

...

2025-08-16 12:43

2300

That's where the r 298 titanium dioxide factory shines. By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced

By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced r 298 titanium dioxide factory. These advances have not only made the production process more environmentally friendly but have also resulted in cost savings for the company.

r 298 titanium dioxide factory. These advances have not only made the production process more environmentally friendly but have also resulted in cost savings for the company.

...

2025-08-16 12:33

1239

Should a grade of lithopone be desired higher than the standard grade and another by-productas, for example, a forty-five*per= cent. grade of lithopone and barium chlorid the following process may be pi'acticed,\vhich, however, is quite analogous to the one already 10o described. Aqueous solutions of the ingredients are prepared as before, in these proportions: zinc sulfate, one hundred and sixty-one pounds; zinc chlorid, one hundred and thirty-six pounds, and barium sulfid, three hundred and thirty-eight pounds. Upon mixing these several solutions the lithopone will at once be precipitated in accordance with the following reaction:

...

2025-08-16 12:27

1197

TiO2 itself was officially first named and created in a laboratory in the late 1800s. It wasn’t mass manufactured until the early 20th century, when it started to take over as a safer alternative to other white pigments.

In conclusion, titanium dioxide (TiO2) is a versatile white pigment with a range of applications in various industries. Its transparency, combined with its other properties such as opacity, brightness, and durability, makes it an attractive option for manufacturers seeking to improve the appearance and functionality of their products. With ongoing research and development, the future of transparent TiO2 looks promising, with new applications and markets emerging as consumers demand more aesthetically pleasing and high-performance products.

That's where the r 298 titanium dioxide factory shines. By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced

By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced By adopting innovative technologies such as pyrolysis and hydrochlorination, the factory has been able to reduce energy consumption by up to 50% while also significantly decreasing the amount of waste produced r 298 titanium dioxide factory. These advances have not only made the production process more environmentally friendly but have also resulted in cost savings for the company.

r 298 titanium dioxide factory. These advances have not only made the production process more environmentally friendly but have also resulted in cost savings for the company.

Should a grade of lithopone be desired higher than the standard grade and another by-productas, for example, a forty-five*per= cent. grade of lithopone and barium chlorid the following process may be pi'acticed,\vhich, however, is quite analogous to the one already 10o described. Aqueous solutions of the ingredients are prepared as before, in these proportions: zinc sulfate, one hundred and sixty-one pounds; zinc chlorid, one hundred and thirty-six pounds, and barium sulfid, three hundred and thirty-eight pounds. Upon mixing these several solutions the lithopone will at once be precipitated in accordance with the following reaction:

Capital Investments

In the dynamic world of industrial chemicals, titanium dioxide stands out as a critical component with widespread applications ranging from paints and coatings to plastics and paper. Within this sector, the production of high-quality rutile titanium dioxide pigment is paramount. The pursuit of excellence leads us to an intriguing exploration of the best pigment rutile manufacturers globally.

The ingredient in question? Titanium dioxide.

With the continuous improvement of people's living standards and the increasing awareness of environmental protection, the application prospects of titanium dioxide powder are becoming increasingly broad. It is believed that in the future, titanium dioxide powder factories will continue to play an important role in promoting economic development and improving people's lives.

Time is often a critical factor in sewing, especially for professionals who rely on quick turnarounds. Heavy duty pattern sewing machines typically boast high-speed stitching capabilities, enabling users to complete projects in significantly less time compared to standard machines. This efficiency not only accelerates productivity but also allows for more experimentation and creativity, as sewers can quickly prototype new ideas without a massive time commitment.

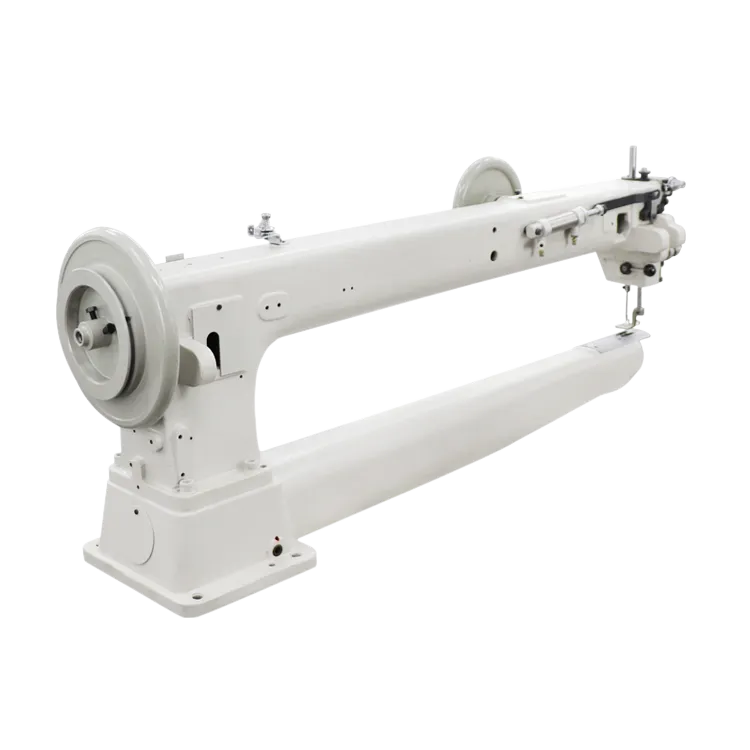

Benefits of Using Cylinder Arm Sewing Machines

In summary, extra heavy duty sewing machines play an indispensable role in modern industry. They not only improve product quality and durability, but also boost technological progress and production efficiency across related sectors. Whether in manufacturing daily items or developing high-tech products, heavy duty sewing machines demonstrate exceptional performance as an essential industrial wonder.

For professionals in industries like upholstery, leatherworking, and heavy fabric sewing, a compound feed heavy-duty sewing machine is a must-have tool. These machines can sew through thick layers of fabric, leather, canvas, and other heavy materials with precision and ease. They can also handle specialized sewing techniques like topstitching, edge stitching, and decorative stitching with ease, making them versatile tools for a wide range of projects.

-

The ingredient in question? Titanium dioxide.

With the continuous improvement of people's living standards and the increasing awareness of environmental protection, the application prospects of titanium dioxide powder are becoming increasingly broad. It is believed that in the future, titanium dioxide powder factories will continue to play an important role in promoting economic development and improving people's lives.

Time is often a critical factor in sewing, especially for professionals who rely on quick turnarounds. Heavy duty pattern sewing machines typically boast high-speed stitching capabilities, enabling users to complete projects in significantly less time compared to standard machines. This efficiency not only accelerates productivity but also allows for more experimentation and creativity, as sewers can quickly prototype new ideas without a massive time commitment.

Benefits of Using Cylinder Arm Sewing Machines

In summary, extra heavy duty sewing machines play an indispensable role in modern industry. They not only improve product quality and durability, but also boost technological progress and production efficiency across related sectors. Whether in manufacturing daily items or developing high-tech products, heavy duty sewing machines demonstrate exceptional performance as an essential industrial wonder.

For professionals in industries like upholstery, leatherworking, and heavy fabric sewing, a compound feed heavy-duty sewing machine is a must-have tool. These machines can sew through thick layers of fabric, leather, canvas, and other heavy materials with precision and ease. They can also handle specialized sewing techniques like topstitching, edge stitching, and decorative stitching with ease, making them versatile tools for a wide range of projects.

%20(200%20%C3%97%20200%20px)%20(2)%20(1).webp)