- Overall, China's dominance as an HPMC supplier stems from its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, China continues to drive advancements in HPMC technology, offering a wide range of products that cater to diverse industry needs. As the demand for HPMC continues to grow worldwide, China's role as a leading supplier is set to expand, solidifying its position as a key player in the global HPMC market.

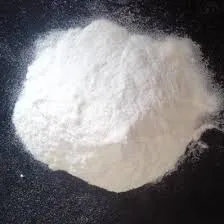

Hydroxypropyl methylcellulose, often abbreviated to HPMC or also called hypromellose, is a chemical compound widely used as an aid in pharmaceutical and food products. HPMC is a type of cellulose ether, a derivative of natural cellulose, which is extracted from plant sources such as wood pulp or cotton fibers. This compound is specifically valued for its ability to serve as a thickener, stabilizer, emulsifier and film former. It has many functions.

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability hydroxy methyl cellulose. It also acts as a retarder, slowing down the setting time of cement, providing more flexibility during construction.

hydroxy methyl cellulose. It also acts as a retarder, slowing down the setting time of cement, providing more flexibility during construction.

hpmc for tile adhesive.

hpmc manufacturers in china.

7. hydroxypropyl methyl cellulose (HPMC) what are the main technical indicators?

hpmc address. Being a bio-based and non-toxic material, it aligns with the growing demand for eco-friendly solutions. This green address positions HPMC as a responsible choice for manufacturers, contributing to a reduced environmental footprint.

hpmc address. Being a bio-based and non-toxic material, it aligns with the growing demand for eco-friendly solutions. This green address positions HPMC as a responsible choice for manufacturers, contributing to a reduced environmental footprint.2)The viscosity of Hydroxypropyl Methylcellulose is influenced by its molecular weight, with higher molecular weight leading to higher viscosity. Temperature also affects its viscosity, with viscosity decreasing as temperature rises. However, the impact of temperature on viscosity is lower compared to Methyl Cellulose. Its solution is stable when stored at room temperature.

6. Is the viscosity of hydroxypropyl methyl cellulose (HPMC) much appropriate?

hpmc chemical structure.

Companies like Fisher Scientific or VWR International have physical stores where you can inspect the product before purchasing Companies like Fisher Scientific or VWR International have physical stores where you can inspect the product before purchasing

Companies like Fisher Scientific or VWR International have physical stores where you can inspect the product before purchasing Companies like Fisher Scientific or VWR International have physical stores where you can inspect the product before purchasing where to buy hydroxyethyl cellulose. They might not always stock HEC, but they can usually source it for you with a lead time.

where to buy hydroxyethyl cellulose. They might not always stock HEC, but they can usually source it for you with a lead time.