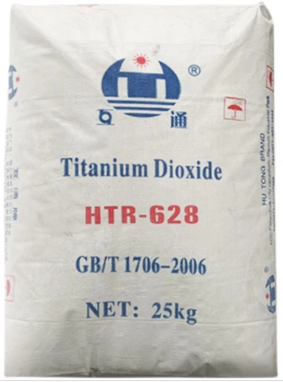

When selecting a supplier of titanium dioxide for nitrile gloves, it is crucial to consider several factors. These include

...

2025-08-16 16:54

1961

On absorption of UV light, photo-generated titanium dioxide particles create singlet oxygen, superoxide anions (O2-) and hydroxyl radicals (OH-) that are potent free radicals (1,2). Irradiated particles of titanium dioxide can induce oxidative damage to DNA (2) which can lead to the development of mutant cells and skin cancers (3,4,5,6) and lipid peroxidation of essential functions on the cell membrane (7).