Overall, titanium dioxide manufacturers play a crucial role in supplying this essential compound to industries around the world. By focusing on quality, sustainability, and innovation, manufacturers can ensure a stable supply of titanium dioxide for years to come.

Lithopone B311

Alterations in gut microbiota

Data availability statement

Rutile Titanium Dioxide (TiO2) is one of the most widely used and versatile materials in various industries, particularly in coatings and plastics. As a leading supplier of MBR9668, a specialized rutile titanium dioxide coating, companies are empowered to enhance the performance and durability of their products significantly. This article explores the unique properties of MBR9668 and its applications across diverse sectors.

Analyst Insight

Zns 28-30% Chemical Provide Lithopone Pigments Low Price

Overwhelmingly, research that’s relevant to human eating patterns shows us that E171 is safe when ingested normally through foods and drugs (1,2).

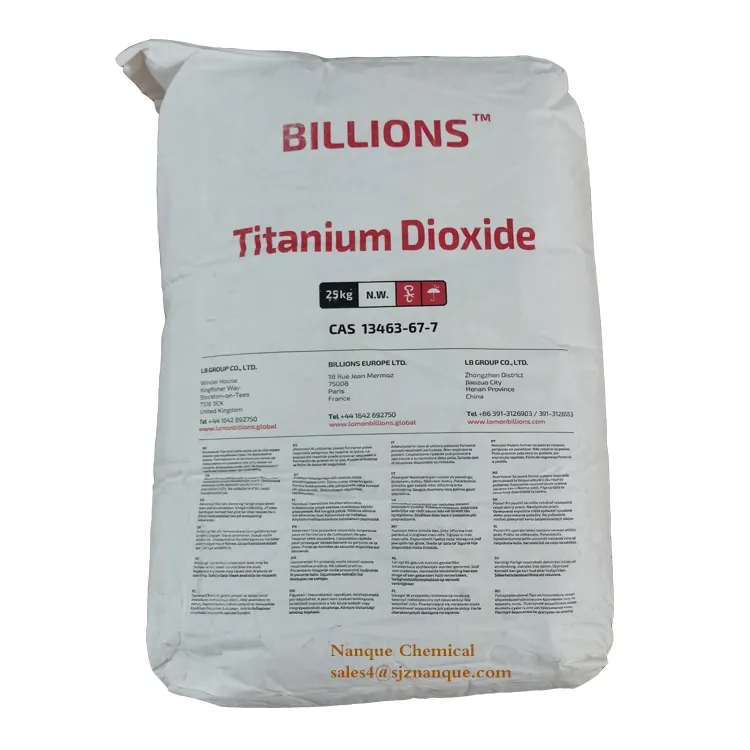

Titanium Dioxide Raw Material Tio2 Powder

Micronized titanium dioxide doesn’t penetrate skin so there’s no need to be concerned about it getting into your body. Even when titanium dioxide nanoparticles are used, the molecular size of the substance used to coat the nanoparticles is large enough to prevent them from penetrating beyond the uppermost layers of skin. This means you’re getting the sun protection titanium dioxide provides with no risk of it causing harm to skin or your body. The coating process improves application, enhances sun protection, and prevents the titanium dioxide from interacting with other ingredients in the presence of sunlight, thus enhancing its stability. It not only makes this ingredient much more pleasant to use for sunscreen, but also improves efficacy and eliminates safety concerns. Common examples of ingredients used to coat titanium dioxide are alumina, dimethicone, silica, and trimethoxy capryl silane.

Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation

Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation Some of the most well-known manufacturers include DuPont, Cristal Global, and Huntsman Corporation