- The Pivotal Role of Floor Marking Tape in Modern Environments

- 4. Temperature Resistance The tape can withstand extreme temperatures ranging from -40°F to 250°F (-40°C to 121°C), making it suitable for use in a variety of applications.

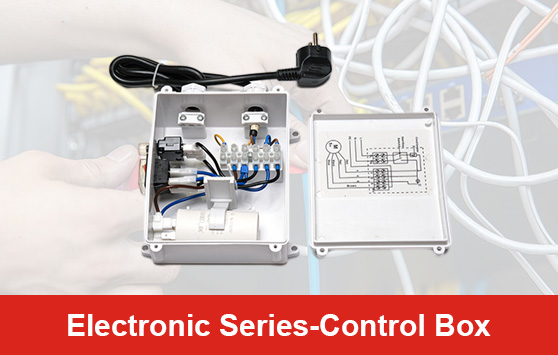

Diving deeper, a control box comprises several critical components, each with a specific function. Here’s a breakdown:

- Another notable feature of the Leak Stopper Rubber Flexx Tape is its resistance to extreme temperatures. Whether you're facing the cold snap of winter or the heatwave of summer, this tape maintains its integrity and effectiveness. It does not become brittle in the cold nor does it lose adhesion in the heat, ensuring year-round reliability.

- The primary purpose of yellow and black tape for floor marking is to clearly define safety zones, warning areas, and designated paths. The bright yellow color is highly visible, making it easy for workers, visitors, and even children to identify and avoid these areas. The black outline provides additional contrast and emphasis, ensuring that the boundaries are unmistakable.

- In conclusion, splicing tape is a versatile and essential tool that is used in a wide range of industries for joining, repairing, and maintaining materials and equipment. Its strong adhesive properties, flexibility, and ease of use make it an invaluable asset for increasing efficiency, productivity, and reliability in various manufacturing processes. Whether in printing, packaging, or maintenance, splicing tape plays a crucial role in ensuring smooth and seamless operations.

- Overall, vulcanizing tape is a versatile and reliable solution for a variety of maintenance and repair needs. Its strong, watertight seal, resistance to chemicals and UV rays, ease of use, and cost-effectiveness make it a valuable tool for professionals and DIY enthusiasts alike. Whether you are repairing a leaky pipe, sealing a hose, or patching up a rubber material, vulcanizing tape is an effective and efficient option that will get the job done.

- 3. Mark the location of electrical outlets, light switches, and other fixtures.

4. Easy Installation Another advantage of fireproof gasket tape is its ease of installation. Most varieties come with a self-adhesive backing, allowing for quick and hassle-free application. This attribute ensures that maintenance teams can swiftly address safety concerns without extensive downtime or complicated procedures.

pvc insulation tape black. Made from high-quality PVC material, this tape is resistant to water, oil, and various chemicals. This makes it ideal for use in harsh environments where other types of tape may fail.

In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

Varnish cambric electrical insulation tape is made of straight-cut woven cotton fabric. Its fabric is primed with oil and coated in an electrical insulating finish. The varnish ensures that the tape remains intact as currents pass through the wire.

Overcurrent Protection Devices

rubber strip for door seal. Homeowners can notice a reduction in energy bills as the strip helps to insulate the indoor environment, keeping heated or cooled air inside where it belongs. Moreover, the strip's soundproofing qualities contribute to a quieter, more peaceful home atmosphere. It also serves as a barrier against pollen, dust, and other allergens, creating a healthier living space for allergy sufferers.

rubber strip for door seal. Homeowners can notice a reduction in energy bills as the strip helps to insulate the indoor environment, keeping heated or cooled air inside where it belongs. Moreover, the strip's soundproofing qualities contribute to a quieter, more peaceful home atmosphere. It also serves as a barrier against pollen, dust, and other allergens, creating a healthier living space for allergy sufferers.The naturally occurring rubber harvested from rubber trees is the oldest type of adhesive base and is still in use today in various masking tapes and applications tapes used in the graphics industry. They are inexpensive, can be formulated with predictable adhesion properties, and work well in applications with low shear requirements. These adhesives work well in ambient and low-temperature applications but will struggle when the temperature exceeds about 120°F.

varnished cambric tape uses.

5. Ease of Use With no messy adhesives to deal with, self-fusing silicone tape is simple to apply. Users can easily wrap it around wires, connectors, and other components, ensuring a secure seal without complications.

Overall, self-fusing tape is a versatile and valuable tool that has a wide range of uses. Whether you're a DIY enthusiast looking for a quick and easy way to fix plumbing or electrical issues, or a professional tradesperson in need of a reliable sealant for various applications, self-fusing tape is a product worth considering. Its strong bonding properties, resistance to heat and water, and ease of use make it a must-have item for any toolbox.

No protective equipment or specialist tools are required to use self-amalgamating tape, and a pair of scissors to cut the tape is all that is needed. The tape features a peel-away backing paper (to stop it from sticking to itself before needed) that has to be removed prior to use. Once the correct length has been cut, and the backing removed, the tape can be stretched and applied; when the tape is being wrapped around a cable, for example, ensure that each layer overlaps the previous. Overlapping in this way enables a stronger bond between layers and a 50% overlap is usually recommended, with 3-4 layers of tape being advised. Stretching the tape as you go will ensure a tighter wrap is created and will help the tape to stick to itself more effectively. The bond between the layers of tape will usually take only a few minutes to form but is capable of enduring for years.

diall self fusing tape. Its high dielectric strength makes it safe to use on electrical components, providing an extra layer of protection against shorts and sparks. The flexibility of the tape allows for easy wrapping around irregular shapes and surfaces.