what color is titanium dioxide

Conclusion

4. Emergency procedures The MSDS should outline steps to take in the event of an accident or exposure to lithopone, including first aid measures and contact information for emergency responders.

...

2025-08-14 06:31

555

The National Cancer Institute tested TiO2 for possible carcinogenicity by the oral route of exposure by feeding rats and mice with TiO2 (size not specified) at doses 25,000 or 50,000 ppm TiO2 for 103 weeks. They concluded that TiO2 was not carcinogenic.Also, the study with rats fed diets containing up to 5 % TiO2 coated mica for 130 weeks showed no treatment-related carcinogenicity. Since the size and other TiO2 properties were not specified or determined, we cannot generalize this conclusion and we have to take into account other possible outcomes of this scenario in different exposure conditions (other size/crystalline structure of TiO2 etc.).

...

2025-08-14 05:44

423

...

2025-08-14 05:31

399

...

2025-08-14 04:52

1555

...

2025-08-14 04:47

881

FDA guidelines:Americans are eating too much salt. So the FDA wants food manufacturers to cut back on sodium.

...

2025-08-14 04:45

1417

Manufacturers of 98% Anatase Titanium Dioxide Paint Grade understand the importance of consistency and quality control in their products. They employ advanced production techniques, such as the sulfate or chloride process, to refine raw materials into the finest grade TiO2. Stringent quality checks are carried out at every stage, from sourcing the highest quality ilmenite or rutile ores to the final product packaging, ensuring the purity and performance of the pigment.

...

2025-08-14 04:35

935

The National Cancer Institute tested TiO2 for possible carcinogenicity by the oral route of exposure by feeding rats and mice with TiO2 (size not specified) at doses 25,000 or 50,000 ppm TiO2 for 103 weeks. They concluded that TiO2 was not carcinogenic.Also, the study with rats fed diets containing up to 5 % TiO2 coated mica for 130 weeks showed no treatment-related carcinogenicity. Since the size and other TiO2 properties were not specified or determined, we cannot generalize this conclusion and we have to take into account other possible outcomes of this scenario in different exposure conditions (other size/crystalline structure of TiO2 etc.).

FDA guidelines:Americans are eating too much salt. So the FDA wants food manufacturers to cut back on sodium.

Manufacturers of 98% Anatase Titanium Dioxide Paint Grade understand the importance of consistency and quality control in their products. They employ advanced production techniques, such as the sulfate or chloride process, to refine raw materials into the finest grade TiO2. Stringent quality checks are carried out at every stage, from sourcing the highest quality ilmenite or rutile ores to the final product packaging, ensuring the purity and performance of the pigment.

The gastrointestinal tract is a complex barrier/exchange system, and is the most important route by which macromolecules can enter the body. The main absorption takes place through villi and microvilli of the epithelium of the small and large intestines, which have an overall surface of about 200 m2. Already in 1922, it was recognized by Kumagai, that particles can translocate from the lumen of the intestinal tract via aggregation of intestinal lymphatic tissue (Peyer’s patch, containing M-cells (phagocytic enterocytes)). Uptake can also occur via the normal intestinal enterocytes. Solid particles, once in the sub-mucosal tissue, are able to enter both the lymphatic and blood circulation.

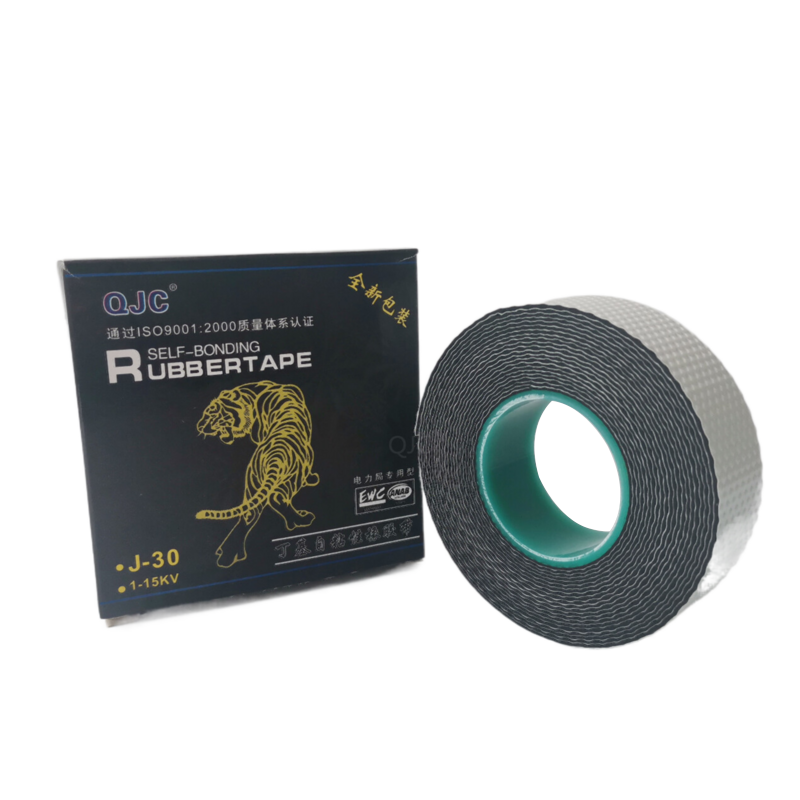

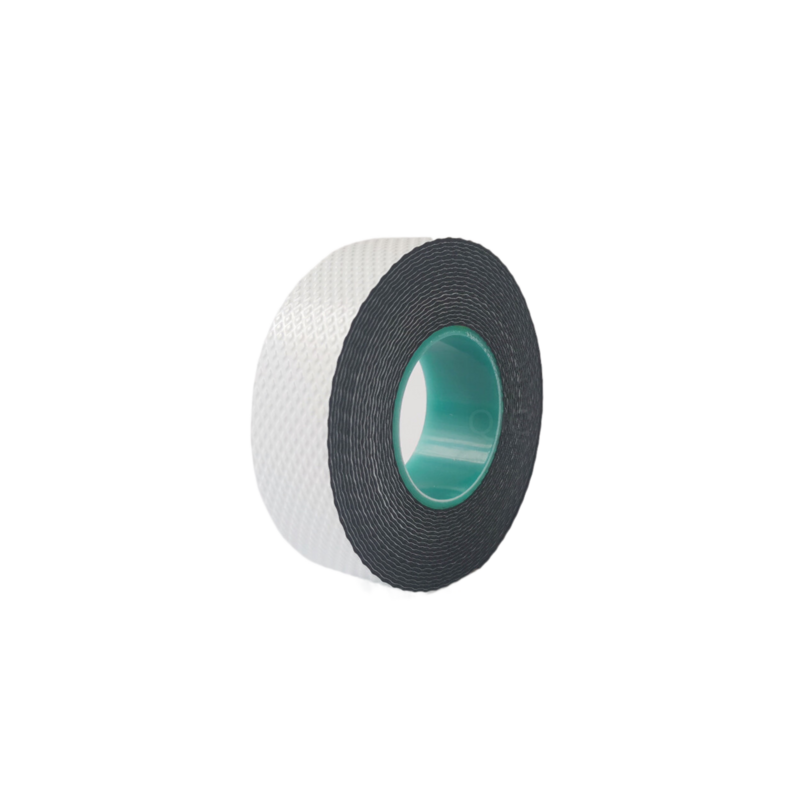

Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating

Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor

The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments