Industrial grade rutile type of titanium dioxide, raw material for the plastic industry

PRODUCT DISPLAY

Integrity management, sufficient inventory, perfect after-sales service, high-quality products,reasonable prices, and thoughtful service.

specification

Integrity management, sufficient inventory, perfect after-sales service, high-quality products,reasonable prices, and thoughtful service.

Industry-specific attributes

| CAS No. | 13463-67-7 |

| Purity | 98% |

Other attributes

| Classification | Titanium Dioxide |

| Place of Origin | Hebei, China |

| Other Names | Anatase Titanium Dioxide |

| MF | TiO2 |

| EINECS No. | 236-675-5 |

| Grade Standard | Industrial Grade |

| Appearance | White Powder |

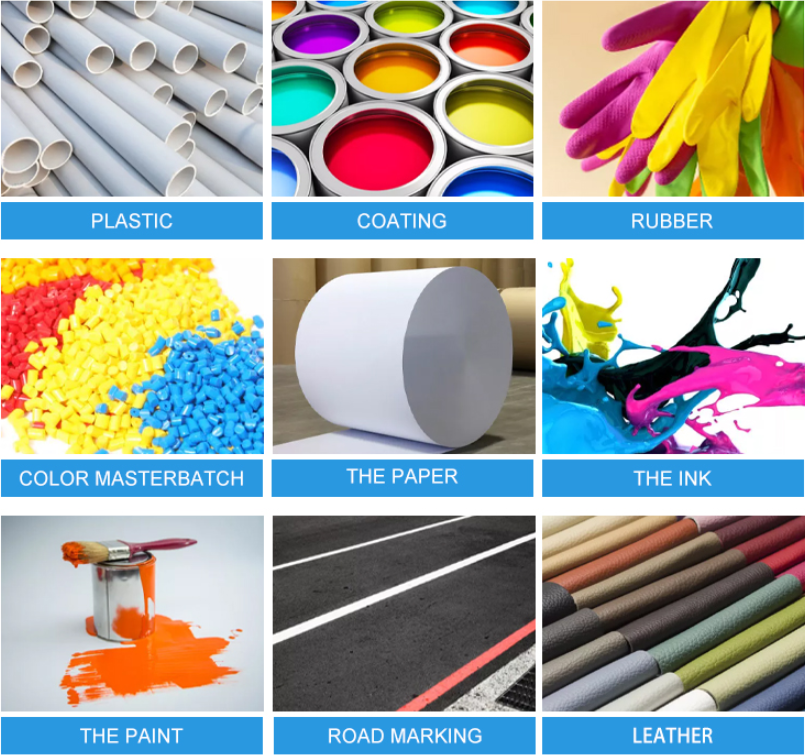

| Application | coating ,Printing ink, section,plastic |

| Product name | Anatase titanium dioxide |

| Color | White Color |

| Package | 25kg/bag |

| Shape | Powder |

| Appearance | White |

| Keywords | White Powder Tio2 Titanium Dioxide |

| Grade | Industrail Grade |

| Usage | Coatings Printing Ink.plastic |

| Other Names | Tio2 |

Lead time

| Quantity (kilograms) | 1 - 25 | 26-1000 | 1001 -25000 | >25000 |

| Lead time (days) | 5 | 7 | 15 | To be negotiated |

APPLICATIONS:

Application of titanium dioxide in plastics industry

Since plastic products are much thicker than paint and ink coatings, they do not require too high a pigment volume concentration. In addition, titanium dioxide has high hiding power and strong coloring power, so the general dosage is only 3%~5%.

Most titanium dioxide particles for plastics are relatively fine. Usually, the particle size of titanium dioxide for coatings is 0.2~0.4μm, while the particle size of titanium dioxide for plastics is 0.15~0.3μm. This can obtain a blue base phase, which has a covering effect on most resins with yellow phases or resins that are prone to yellowing.

Ordinary titanium dioxide for plastics is generally not surface treated, because titanium dioxide coated with inorganic substances such as conventional hydrated alumina has an adsorption equilibrium water of about 1% at a relative humidity of 60%. When plastics are extruded at high temperatures, water evaporation will cause pores to appear on the smooth plastic surface.

With the continuous expansion of the application scope of plastic products, many external plastic products, such as plastic doors and windows, building materials and other outdoor plastic products, also have high requirements for weather resistance. In addition to the use of rutile titanium dioxide, surface treatment is also required. This surface treatment generally does not add zinc, but only silicon, aluminum, zirconium, etc. Silicon has a hydrophilic dehumidification effect, which can prevent the formation of pores due to water evaporation when the plastic is extruded at high temperature.

Titanium dioxide plays an important role in the plastic industry and has broad application prospects. I believe that under the current situation of rapid development of the plastic industry, the titanium dioxide industry will also be better developed.

company profile

Integrity management, sufficient inventory, perfect after-sales service, high-quality products,reasonable prices, and thoughtful service.

packaging delivery

Integrity management, sufficient inventory, perfect after-sales service, high-quality products,reasonable prices, and thoughtful service.

company style

Integrity management, sufficient inventory, perfect after-sales service, high-quality products,reasonable prices, and thoughtful service.