10 月 . 09, 2024 14:07 Back to list

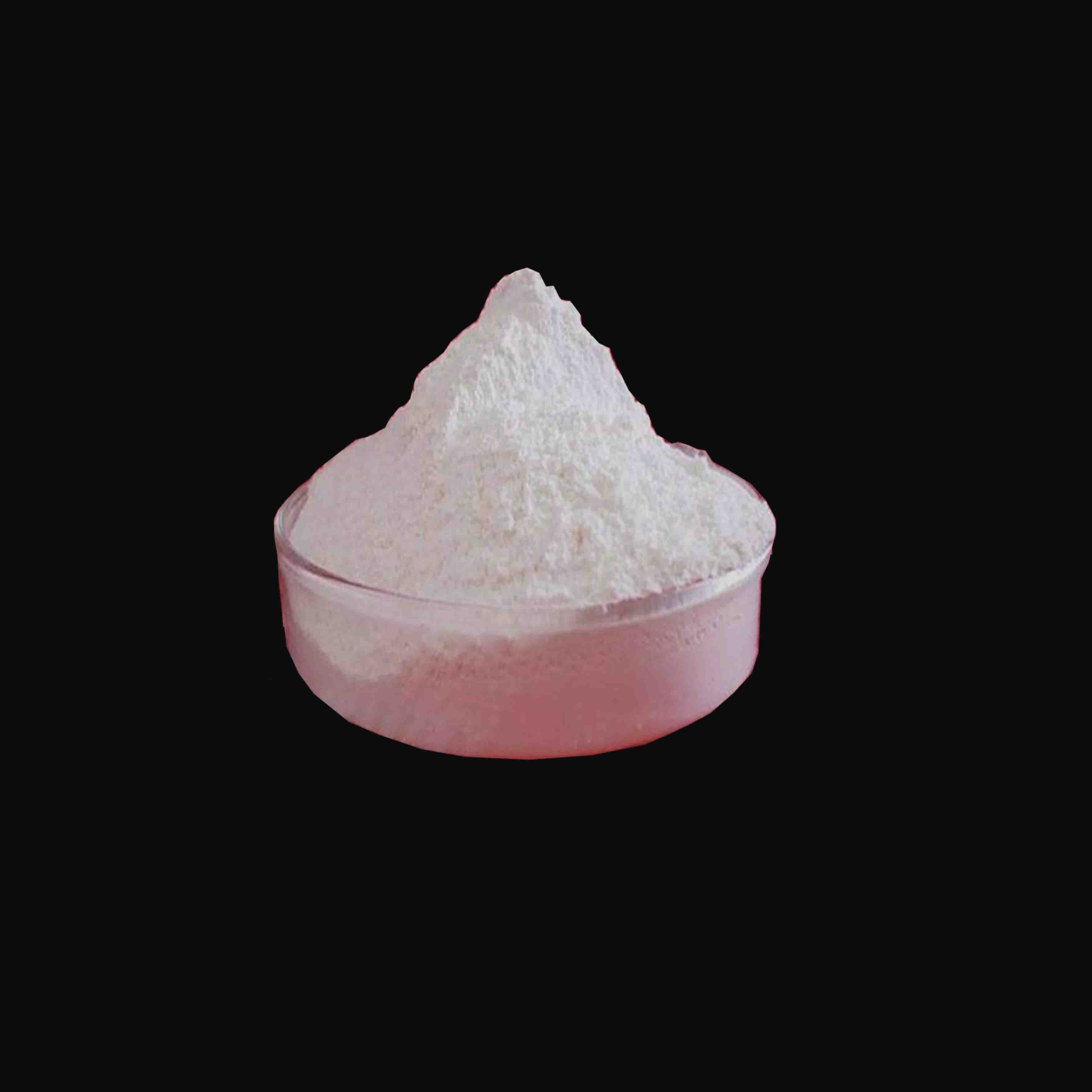

High-Quality 1250 Mesh Manufacturing for Optimal Performance and Precision Applications

The Significance of a 1250 Mesh Factory in Today's Industrial Landscape

In the contemporary industrial environment, the demand for finely processed materials has skyrocketed. One such critical factor in achieving the requisite material quality is the mesh size. A 1250 mesh factory, specializing in the production of high-precision mesh materials, plays a pivotal role in numerous sectors, including pharmaceuticals, food processing, cosmetics, and chemicals.

To understand the importance of a 1250 mesh factory, it’s essential to recognize what mesh means in this context. The mesh size indicates the number of openings in a one-inch screen; for example, a 1250 mesh means there are 1250 openings in every inch, resulting in extremely fine particles. This ultra-fine material is essential for applications requiring precise particle sizes that ensure uniformity and effectiveness in the end product.

The manufacturing process in a 1250 mesh factory is rigorous and technologically advanced

. It involves the use of sophisticated milling and screening equipment that can grind raw materials to the desired fineness, then classify them according to size. Quality control measures are stringent, ensuring that every batch meets specified criteria. This attention to detail not only aids in maintaining product quality but also enhances the factory's reputation in a competitive market.1250 mesh factory

A 1250 mesh factory also significantly contributes to sustainability. Many modern factories focus on eco-friendly practices, ensuring that waste material is minimized and energy consumption is optimized. Through innovative techniques, these facilities can recycle byproducts and reduce emissions, aligning with global standards for environmental protection.

Moreover, the versatility of products produced in a 1250 mesh factory cannot be overstated. For example, in pharmaceuticals, ultra-fine powders are crucial for drug formulation, affecting the drug's bioavailability and overall effectiveness. Similarly, in the food industry, such fine materials are vital for flavoring, thickening, and preserving food items, ultimately enhancing product quality.

The future looks promising for 1250 mesh factories. With the ongoing advancements in technology and increasing regulations demanding higher product quality, the importance of such specialized manufacturers is only set to grow. Industries are recognizing the value of investing in high-quality materials and the role that precision manufacturers play in achieving these goals.

In conclusion, a 1250 mesh factory is not just a production facility; it is a cornerstone of modern manufacturing that supports diverse industries by providing the finely processed materials essential for innovation and quality enhancement. As industries continue to evolve, the significance of such specialized production facilities will undoubtedly remain crucial to meeting both current and future demands.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025