8 月 . 22, 2024 01:37 Back to list

2028 Titanium Dioxide Production Trends and Future Factory Developments in the Industry

The Rise of Titanium Dioxide Factories A Focus on TR2028

In recent years, the demand for titanium dioxide (TiO2) has surged, driven by its broad application across various industries, including paints, coatings, plastics, and even food products. An important development in this context is the establishment of TR2028 titanium dioxide factories, which are vital for meeting the increasing global demand for high-quality TiO2. This article delves into the significance of TR2028 titanium dioxide factories, their production processes, environmental considerations, and future prospects.

Understanding Titanium Dioxide

Titanium dioxide is a white pigment known for its outstanding opacity and brightness. Due to these attributes, it is widely used in paints, coatings, and inks, enhancing the durability and aesthetic appeal of products. Beyond its role as a pigment, TiO2 has applications in sunscreens, where it acts as a UV filter, and in photocatalysis, helping to break down pollutants.

The Emergence of TR2028 Factories

The designation TR2028 refers to a specific initiative or framework aimed at establishing advanced titanium dioxide production facilities that adhere to stringent quality and environmental standards. These factories are equipped with the latest technology to enhance efficiency and minimize waste. The TR2028 initiative marks a significant leap forward in TiO2 production, as it prioritizes not only output but also sustainability.

TR2028 factories utilize state-of-the-art processes, such as the sulfate and chloride processes, to produce TiO2. The sulfate process involves using sulfuric acid, while the chloride process employs chlorine and titanium-bearing ore. The chloride process is generally considered more environmentally friendly, producing fewer by-products and allowing for better recovery of TiO2.

Environmental Considerations

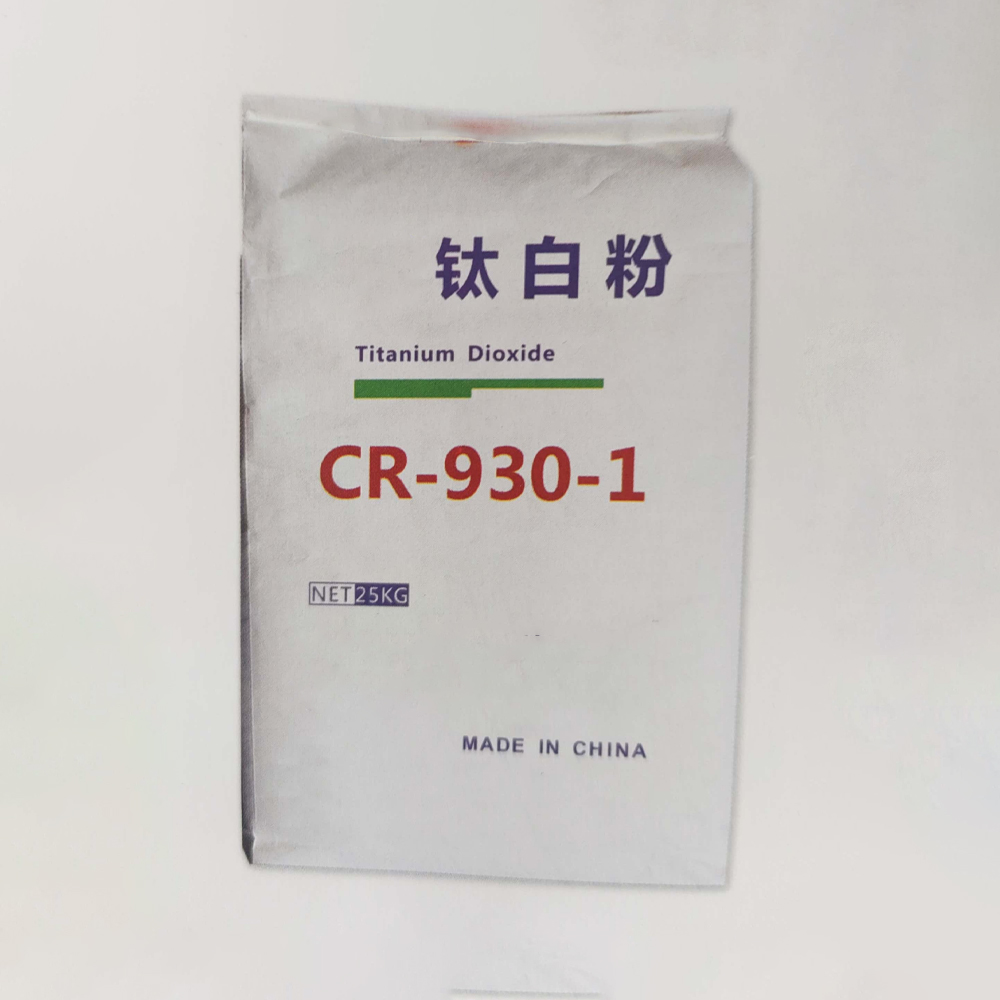

tr 28 titanium dioxide factories

The establishment of TR2028 titanium dioxide factories brings to the forefront the importance of environmental stewardship in industrial operations. The production of TiO2 can have significant environmental impacts, including air and water pollution and the generation of hazardous waste. However, TR2028 factories are designed with sustainability in mind. These facilities incorporate advanced filtration and recycling systems to reduce emissions and waste, ensuring compliance with environmental regulations.

Moreover, many TR2028 initiatives focus on the circular economy, aiming to minimize resource extraction and maximize recycling. By adopting sustainable practices, these factories not only contribute to the reduction of their carbon footprint but also enhance their long-term viability and public acceptance.

Future Prospects and Innovations

The future of TR2028 titanium dioxide factories appears promising, thanks to ongoing innovations in production technologies and materials. Researchers and companies are exploring alternative feedstocks and methods to produce TiO2 more sustainably. For instance, there is a growing interest in bio-based processes that utilize renewable materials, potentially reducing dependency on traditional mining for titanium resources.

Another promising avenue is the development of nanostructured TiO2 materials, which can enhance performance in applications such as solar cells and photocatalytic systems. As technologies continue to evolve, TR2028 factories will likely play a crucial role in driving forward the innovation landscape within the TiO2 industry.

Conclusion

The establishment of TR2028 titanium dioxide factories represents a significant advancement in the production of this essential material. By focusing on sustainable practices, advanced technologies, and environmental compliance, these factories not only meet the increasing global demand for TiO2 but also pave the way for a more responsible and innovative industrial future. As the world continues to seek sustainable solutions, the role of titanium dioxide in various applications will only become more prominent, ensuring that TR2028 factories remain at the forefront of this essential industry.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025