9 月 . 30, 2024 15:35 Back to list

Manufacturer of High Purity 98 Percent Anatase Titanium Dioxide for Paint Applications

The Rise of 98% Anatase Titanium Dioxide Paint Grade A Key Player in Modern Coatings

In recent years, the demand for high-quality pigments in the coating industry has surged, primarily due to the expanding automotive, construction, and consumer goods sectors. At the forefront of this demand is titanium dioxide (TiO2), specifically in its anatase form, which has become increasingly popular among manufacturers. With a purity level of 98%, anatase titanium dioxide paint grade is revolutionizing the way we think about coatings, providing exceptional performance and versatility.

Titanium dioxide is renowned for its superior whiteness, high refractive index, and excellent UV resistance. These properties make it an ideal choice for pigments in various applications, including paints, varnishes, and plastics. The anatase form of titanium dioxide, specifically, is characterized by its finer particle size and better coverage ability, making it particularly suitable for high-quality paint formulations.

One of the most significant advantages of using 98% anatase titanium dioxide in paint production is its ability to enhance the brightness and whiteness of coatings. Manufacturers are continuously seeking solutions that not only improve the aesthetics of their products but also provide long-lasting durability. The high purity level of 98% ensures that the pigments maintain their effectiveness over time, preventing issues such as yellowing or fading, which are often seen with lower-quality alternatives.

Moreover, anatase titanium dioxide has excellent dispersion properties, allowing for easy mixing with solvents and other components in paint. This results in a smoother application and a more uniform finish, which is essential for industrial and decorative coatings. The fine particle size of anatase enhances its coverage and opacity, requiring less pigment to achieve the desired color strength. This not only saves costs for manufacturers but also results in more environmentally friendly formulations, as less material is needed to achieve high performance.

98% anatase titanium dioxide paint grade manufacturer

In addition to its visual appeal, 98% anatase titanium dioxide offers superb chemical stability and resistance to weathering. Paints that incorporate this high-grade titanium dioxide are less likely to suffer from degradation when exposed to harsh environmental conditions, such as UV radiation, moisture, and temperature fluctuations. This trait is particularly important in outdoor applications, where coatings are subject to constant exposure to the elements.

The demand for eco-friendly products is rapidly increasing, and the coatings industry is no exception. Manufacturers are now prioritizing sustainable and low-VOC (volatile organic compounds) formulations. Thanks to its natural properties, 98% anatase titanium dioxide can support these initiatives by enabling the creation of cleaner, safer, and more efficient paint systems. By replacing traditional toxic pigments with this sustainable alternative, manufacturers can align their products with evolving consumer preferences and regulatory standards.

As the market for top-tier paint formulations grows, it is crucial for manufacturers to partner with reliable suppliers of 98% anatase titanium dioxide. Choosing the right manufacturer not only ensures the quality of the pigments but also influences the overall performance of the final product. Suppliers offering rigorous quality control, technical support, and comprehensive service can make a significant difference in the efficiency and effectiveness of paint production.

In conclusion, 98% anatase titanium dioxide paint grade is poised to play a vital role in the future of the coatings industry. Its superior whiteness, durability, and eco-friendly characteristics make it an indispensable ingredient for manufacturers aiming to develop high-quality paints that meet modern standards. As the industry evolves, the continued integration of such high-performance materials will be essential in meeting consumer demands for both aesthetic appeal and environmental responsibility.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

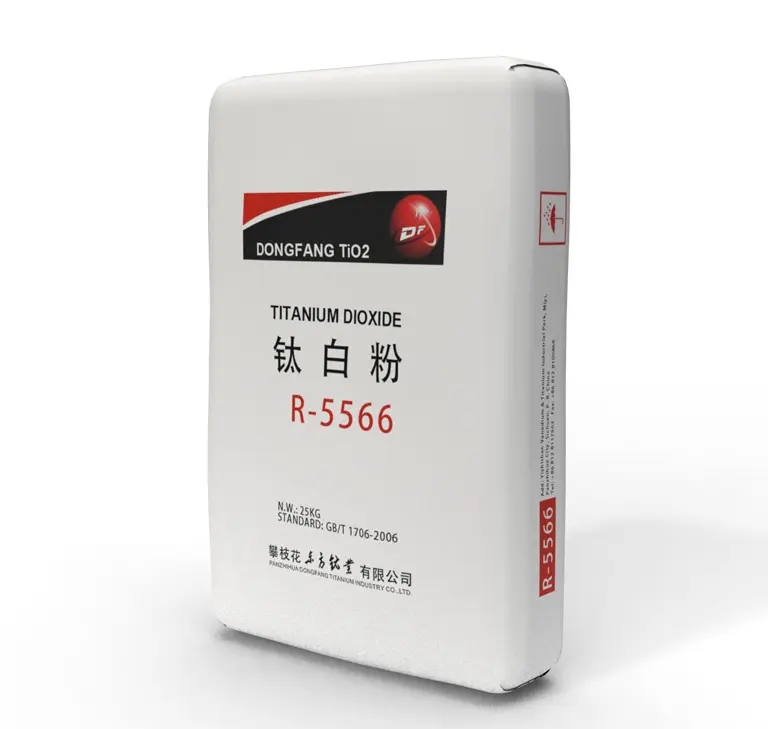

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025