10 月 . 16, 2024 12:25 Back to list

about titanium dioxide factory

The Role of Titanium Dioxide Factories in Modern Industry

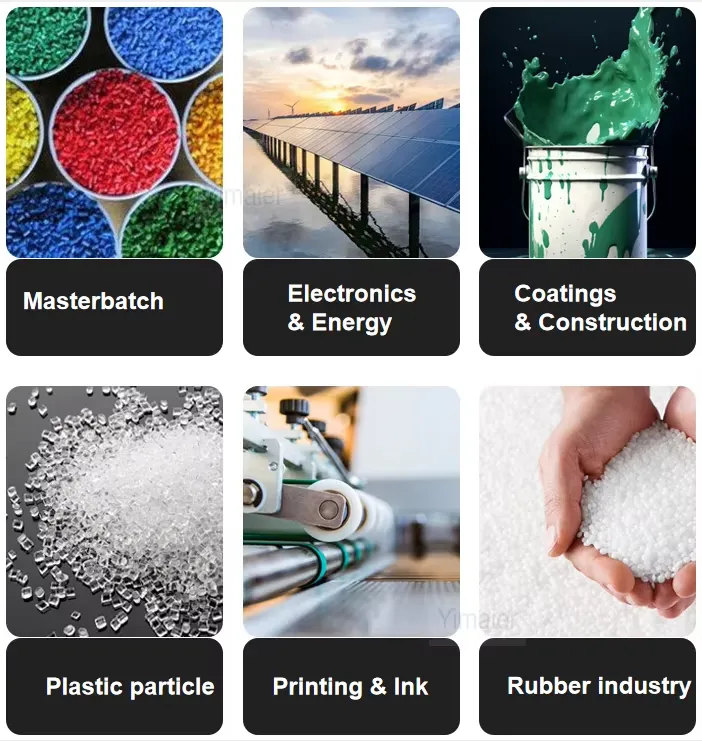

Titanium dioxide (TiO2) is a widely utilized compound known for its excellent properties, including high refractive index, strong ultraviolet light absorption, and excellent stability. These attributes make it an essential ingredient in a variety of products ranging from paints and coatings to cosmetics and plastics. The manufacturing process and operations of titanium dioxide factories play a crucial role in meeting the global demand for this versatile material.

The Role of Titanium Dioxide Factories in Modern Industry

On the other hand, the chloride process, although initially more costly, has gained popularity due to its environmental advantages. In this method, titanium ores are reacted with chlorine gas, resulting in pure titanium tetrachloride, which is then oxidized to produce titanium dioxide. This process yields a purer product and generates less waste, aligning better with modern environmental regulations and sustainability goals.

about titanium dioxide factory

Titanium dioxide factories are usually situated near titanium ore deposits, which allows for efficient logistical operations. The raw materials required for production, such as ilmenite, rutile, and anatase, need to be sourced with consideration for both cost and environmental impact. As the demand for titanium dioxide continues to rise, especially in sectors such as construction and automotive, factories must adopt innovative technologies to increase efficiency and reduce the ecological footprint.

The economic impact of titanium dioxide manufacturing is significant. This industry supports jobs in various sectors—from mining and transportation to manufacturing and marketing. It also contributes to the global economy by supplying industries that produce paints, plastics, and food additives. As consumer awareness of eco-friendly products grows, there is an increasing market for titanium dioxide produced through sustainable practices.

Furthermore, titanium dioxide is essential in meeting regulations related to product safety and environmental standards. In coatings, for instance, it provides opacity and whiteness without compromising safety. Its UV-blocking capabilities make it invaluable in sunscreens and other skincare products, enhancing protective qualities against harmful solar radiation.

In conclusion, titanium dioxide factories are integral to the modern industrial landscape. As they continue to evolve, focusing on sustainable practices and innovative production techniques, they will play a vital role in supporting various industries while addressing the growing concerns about environmental sustainability. The shift toward cleaner production processes not only benefits the planet but also aligns with the increasing demand for high-quality, safe products in a rapidly changing marketplace.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025