8 月 . 01, 2024 00:07 Back to list

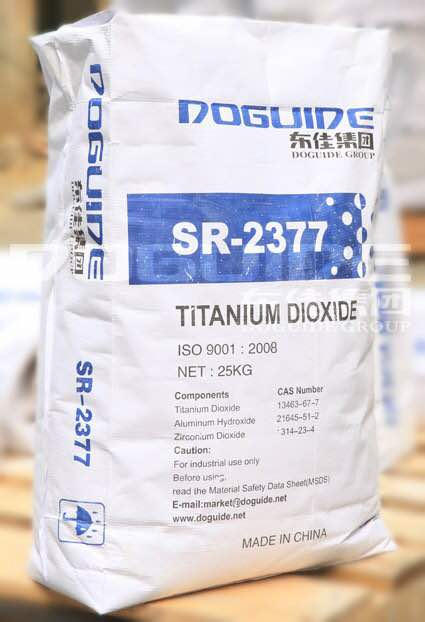

Alternative Approaches to Sourcing High-Quality Titanium Dioxide from Leading Manufacturers and Suppliers

Dissolving Titanium Dioxide Impact and Innovations in the Industry

Titanium dioxide (TiO2) is one of the most widely used industrial materials, known primarily for its exceptional brightness and high refractive index. Its applications range from paints and coatings to plastics, food products, and cosmetics. However, the production and application of titanium dioxide have faced scrutiny due to environmental concerns and the need for innovative solutions in manufacturing. One significant area of focus is the process of dissolving titanium dioxide, a crucial step in various applications.

The dissolution of titanium dioxide is essential for creating products that require a more refined particle size or a specific dispersion in solutions

. Introducing innovative methods for dissolving titanium dioxide can improve product formulation, enhance performance, and reduce environmental impact. Manufacturers are increasingly investing in research and development to find new techniques and methodologies that ensure effective dissolution while minimizing waste and energy consumption.One prominent sector that benefits from the effective dissolution of titanium dioxide is the paint and coatings industry. TiO2 is renowned for its ability to provide opaque and white finishes, making it a staple in manufacturing paints. For coatings to adhere well and provide long-lasting effects, the dissolution process must ensure that TiO2 particles are evenly distributed throughout the medium. Advanced dispersion technologies, including high-shear mixing and ultrasonic dispersion, are gaining traction in the industry, allowing for better control over particle size and distribution.

dissolving titanium dioxide manufacturers

Another critical aspect of dissolving titanium dioxide lies in its environmental footprint. Traditional methods of producing and processing titanium dioxide often use hazardous chemicals, leading to toxic byproducts and significant energy consumption. As sustainability becomes a stronger focus across industries, titanium dioxide manufacturers are exploring more eco-friendly practices. For instance, the use of organic solvents or biodegradable agents in the dissolution process can significantly reduce environmental impact while maintaining product quality.

Moreover, innovative advancements in nanotechnology are enhancing the dissolution of titanium dioxide. The production of nano-sized TiO2 has opened new avenues for applications, particularly in the field of sunscreens and cosmetics. These nano-sized particles allow for improved UV protection while being lightweight and non-greasy. However, the dissolution of these particles requires precision and control to achieve the desired outcome. Manufacturers are now employing cutting-edge methods, including sol-gel techniques, to create stable dispersions of nano-TiO2 effectively.

Partnerships between manufacturers and research institutions are also fostering innovation in the dissolution of titanium dioxide. Collaborative efforts can lead to the development of new formulations and processes that enhance product performance and reduce harmful emissions. As the demand for environmentally friendly products continues to rise, manufacturers are under pressure to innovate, and these partnerships serve as a catalyst for change.

In conclusion, the dissolution of titanium dioxide is a critical process for achieving optimal performance in various applications, from paints to cosmetics. As the industry confronts environmental challenges, manufacturers are focusing on innovative solutions that marry efficiency with sustainability. Advancements in dispersion techniques, eco-friendly practices, and collaborations with research institutions are driving change, ultimately leading to better products and a reduced environmental footprint. The future of titanium dioxide manufacturing hinges on these innovations, setting a pathway toward a more sustainable and technologically advanced industry.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025