10 月 . 21, 2024 23:44 Back to list

High-Quality Anatase Grade Titanium Dioxide Production Facility Solutions

An Overview of Anatase Grade Titanium Dioxide Production

Titanium dioxide (TiO₂) is a versatile white pigment widely used in various industries, including paints, plastics, cosmetics, and food. Among the various crystalline forms of titanium dioxide, anatase and rutile are the two most common. This article focuses on anatase grade titanium dioxide, its properties, applications, and the manufacturing processes involved in its production in factories.

What is Anatase Grade Titanium Dioxide?

Anatase is one of the three primary mineral forms of titanium dioxide, the other two being rutile and brookite. Anatase is characterized by its tetragonal crystal structure and is widely regarded for its high surface area and superior photocatalytic properties compared to rutile. These features make anatase grade titanium dioxide particularly useful in applications that require high reactivity, such as in photocatalysis and environmental remediation.

Properties of Anatase Grade Titanium Dioxide

Anatase grade titanium dioxide is known for its excellent brightness and high refractive index, making it an ideal choice for applications requiring strong opacity and hiding power. Additionally, it exhibits strong UV absorption properties, which are beneficial in protecting products from photodegradation. The unique characteristics of anatase also contribute to its high photocatalytic activity, enabling it to facilitate chemical reactions upon exposure to light.

Applications of Anatase Grade Titanium Dioxide

The applications of anatase grade titanium dioxide are diverse

1. Coatings and Paints Its high opacity and brightness make it a preferred choice for manufacturers of paints and coatings. The use of anatase in exterior paints can enhance durability and resistance to degrading effects of sunlight.

anatase grade titanium dioxide factory

3. Photocatalytic Applications The photocatalytic properties of anatase make it ideal for applications in air and water purification. Photocatalytic coatings using anatase can break down harmful pollutants under UV light, making them effective for self-cleaning surfaces as well.

4. Sunscreens and Cosmetics In cosmetics, anatase grade titanium dioxide is used in sunscreens due to its ability to absorb UV radiation, providing protection against harmful rays.

5. Food and Pharmaceuticals It is also employed in the food industry as a coloring agent and in pharmaceuticals for similar purposes.

Production Processes

The manufacturing of anatase grade titanium dioxide typically involves two primary processes the sulfate process and the chloride process.

1. Sulfate Process This traditional method begins with the sulfate leaching of ilmenite or titanium-rich minerals. The titanium is then precipitated using sulfuric acid, leading to the formation of titanium sulfate. After precipitation, the titanium sulfate is hydrolyzed to produce titanium dioxide hydrate, which is subsequently calcinated at lower temperatures to yield anatase grade TiO₂. This process may result in higher impurities compared to the chloride method.

2. Chloride Process A more modern and cleaner method, the chloride process relies on converting titanium-containing ores into titanium tetrachloride (TiCl₄) by reacting with chlorine gas at elevated temperatures. This TiCl₄ is then oxidized to produce high-purity titanium dioxide. The chloride process is known for its efficiency and lower environmental impact due to fewer waste products.

Conclusion

Anatase grade titanium dioxide plays a critical role in various industries due to its unique properties and versatile applications. As environmental concerns continue to grow, the demand for high-quality, sustainable materials emphasizes the need for efficient manufacturing processes. Factories producing anatase TiO₂ must focus on incorporating greener practices without compromising on quality to meet the evolving market demands. With its myriad applications and inherent benefits, anatase grade titanium dioxide remains integral to advancing technologies in multiple sectors, driving innovation in both product development and environmental sustainability.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

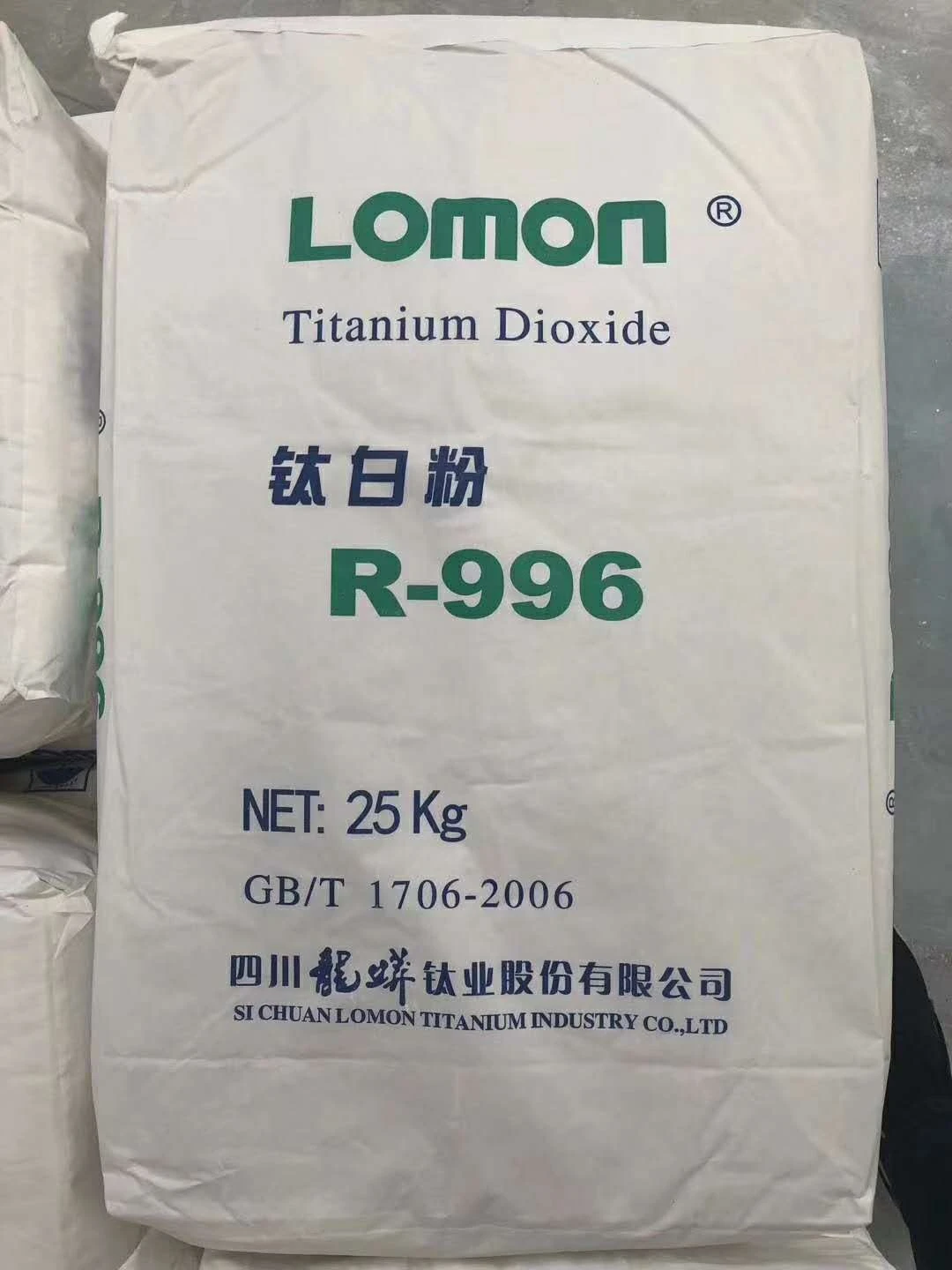

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025