9 月 . 23, 2024 04:51 Back to list

anatase titanium dioxide in coatings factory

The Role of Anatase Titanium Dioxide in Coatings Manufacturing

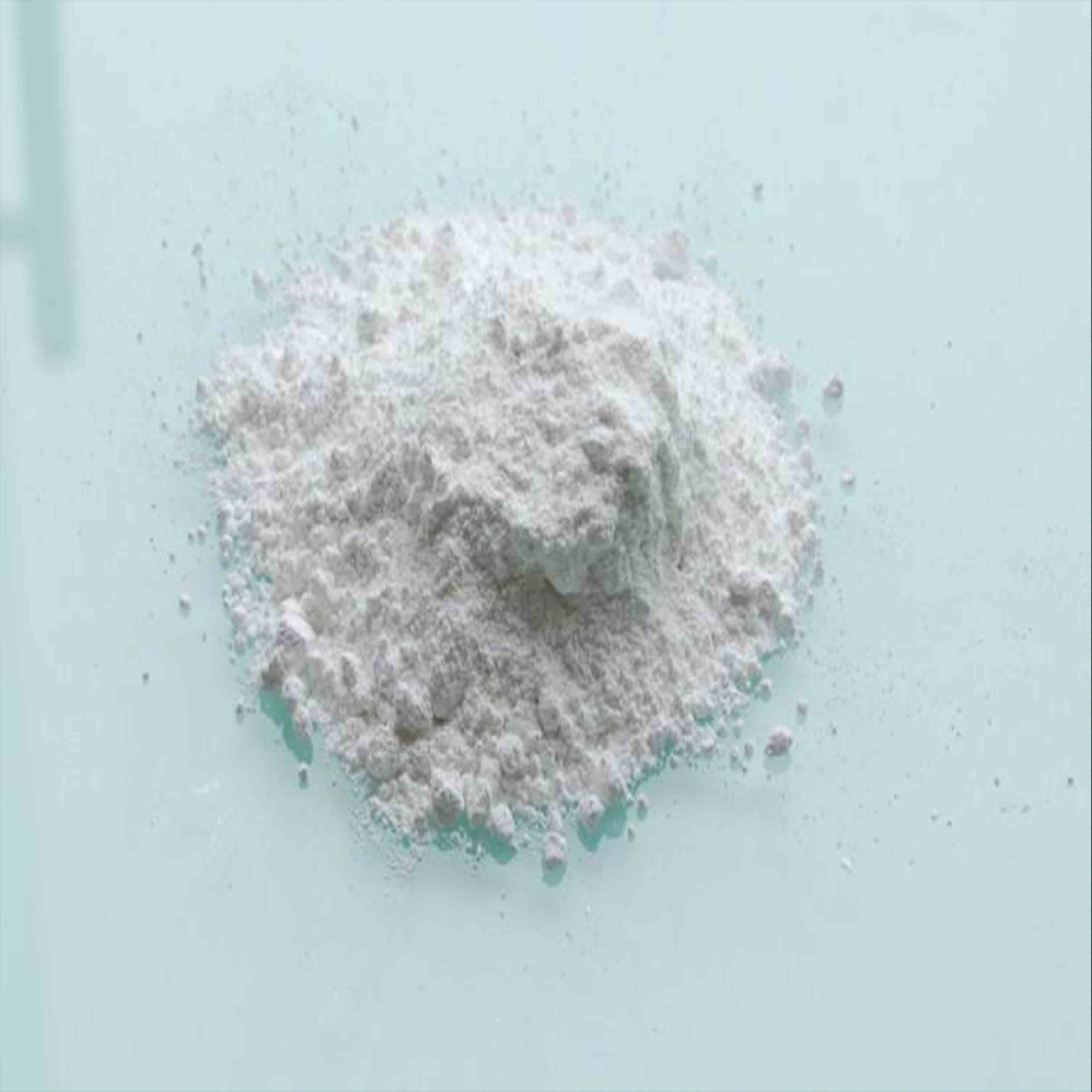

Anatase titanium dioxide (TiO2) has become an indispensable component in the coatings industry, known for its remarkable properties that enhance both the aesthetic and functional characteristics of various coatings

. This white, inorganic compound exhibits excellent UV resistance, high durability, and exceptional opacity, making it a popular choice for manufacturers looking to improve their products.One of the primary reasons for anatase TiO2’s prominence in coatings is its outstanding ability to scatter light. This property allows coatings to achieve a bright white finish and maintain a high degree of color retention over time. In applications where aesthetics are paramount, such as in architectural coatings and automotive finishes, the use of anatase TiO2 ensures that the end products are visually appealing and can withstand environmental factors that typically cause fading and discoloration.

Moreover, anatase titanium dioxide possesses excellent photocatalytic properties, which enable it to decompose organic pollutants under UV light. This characteristic has led to its use in self-cleaning coatings that are particularly valuable in urban settings, where pollution and grime can accumulate quickly. By integrating anatase TiO2 into their formulations, manufacturers can offer products that not only look good but also promote a cleaner environment.

anatase titanium dioxide in coatings factory

In addition to its aesthetic qualities, anatase TiO2 contributes significantly to the durability of coatings. It enhances the mechanical strength and weather resistance of the paint, ensuring that it adheres well to surfaces and withstands the rigors of time. This durability means fewer repainting cycles, ultimately leading to cost savings for consumers and reduced environmental impact from frequent maintenance.

However, the effectiveness of anatase TiO2 in coatings is also influenced by the formulation and processing techniques employed by manufacturers. Optimizing particle size and distribution, as well as ensuring uniform dispersion within the coating matrix, are crucial factors that can enhance the performance of the final product. Advances in nanotechnology have led to the development of engineered TiO2 particles which can provide even greater benefits, such as improved opacity and lower usage rates without compromising quality.

In conclusion, anatase titanium dioxide is a vital ingredient in modern coatings manufacturing. Its unique properties contribute not only to the visual appeal and durability of coatings but also offer environmental benefits. As the coatings industry continues to evolve, the innovative applications of anatase TiO2 will undoubtedly play a significant role in meeting consumer demands for both performance and sustainability.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025