9 月 . 11, 2024 07:18 Back to list

China Titanium Dioxide Production Line - Advanced Manufacturing Solutions

The Evolution of Titanium Dioxide Production in China

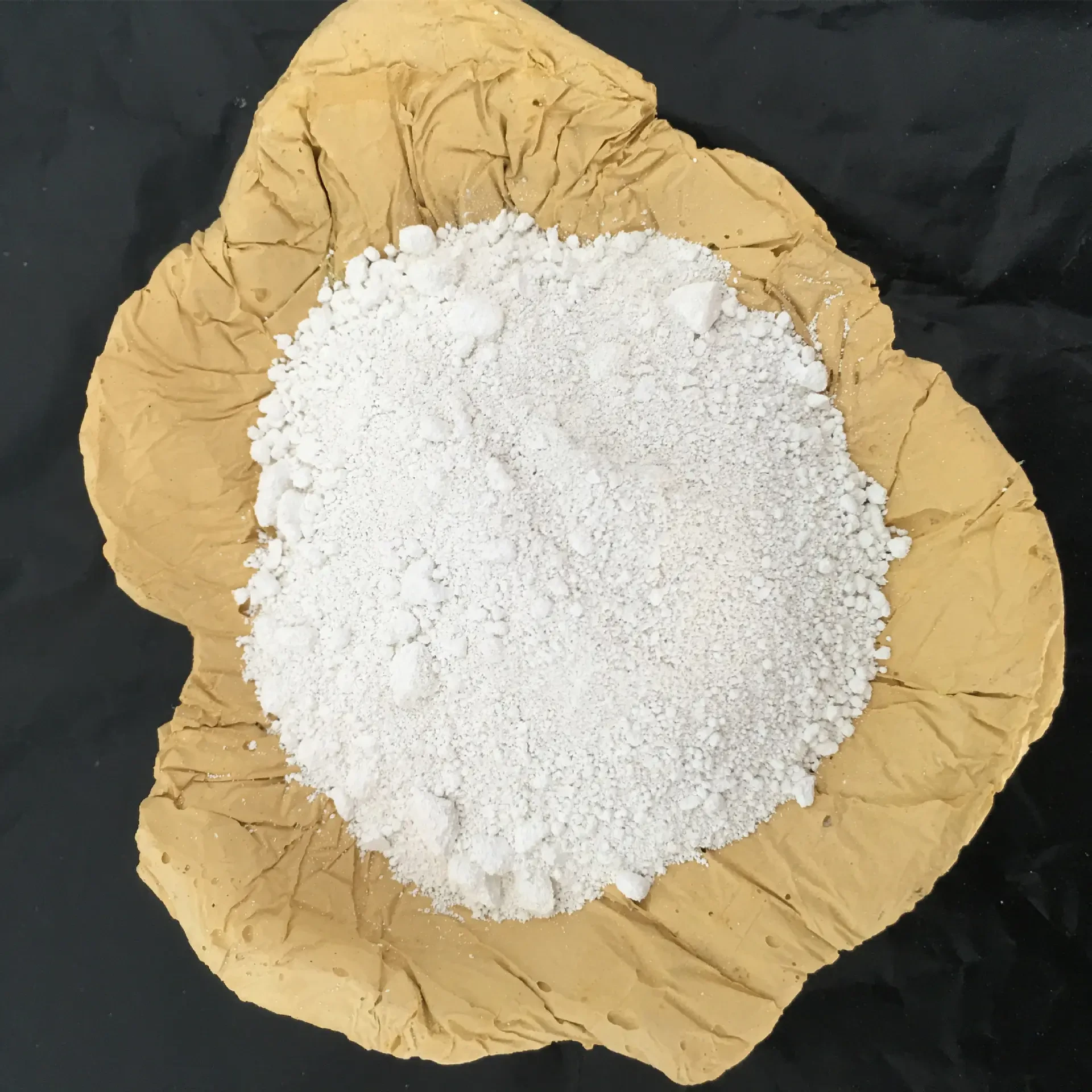

Titanium dioxide (TiO2) is a vital industrial pigment widely used in various applications, including paints, coatings, plastics, and cosmetics. It is renowned for its high refractive index and opacity, making it an essential component for achieving desired aesthetics and durability in products. As the demand for titanium dioxide continues to grow globally, China's production lines for this essential material have evolved significantly over the years.

China is now one of the largest producers of titanium dioxide in the world. This rapid growth can be attributed to a combination of factors, including increased domestic demand, investment in advanced technology, and the accessibility of ample titanium ore resources. The country's production methods have shifted from traditional processes to more modern, automated, and environmentally friendly techniques, reflecting a broader commitment to sustainability and efficiency.

Historically, the production of titanium dioxide in China primarily relied on the sulfate process, which, while effective, produced a considerable amount of waste and required significant energy inputs. However, the rise of the chloride process has revolutionized the industry. The chloride process not only leads to higher purity TIO2 but also generates less waste and is overall more cost-effective. As a result, many Chinese manufacturers have invested heavily in transitioning to this more efficient method, thus enhancing their competitive edge in the global market.

china china titanium dioxide production line

In addition to technological advancements, China's government plays a pivotal role in shaping the titanium dioxide production landscape. Policies that promote high-tech industries and environmental standards have encouraged companies to innovate and improve production processes. Moreover, international collaborations and partnerships have facilitated the transfer of advanced technologies and know-how, further propelling the development of titanium dioxide production lines across the country.

As a result of these efforts, Chinese titanium dioxide manufacturers are increasingly focusing on product diversification to meet varying customer needs. High-performance grades of titanium dioxide are now being produced for demanding applications such as automotive coatings, aerospace, and specialized industrial uses. This diversification not only supports the domestic economy but also enhances China's position as a key player in the global titanium dioxide market.

Looking to the future, the Chinese titanium dioxide industry is poised for further growth. Continuous investments in research and development are expected to lead to breakthroughs in production efficiency and sustainability. Furthermore, as global trends shift towards greener and more sustainable practices, Chinese manufacturers are likely to prioritize innovations that minimize environmental impacts while maximizing output.

In summary, China's titanium dioxide production line has transformed significantly, driven by technological advancements, supportive government policies, and growing market demands. As the industry continues to evolve, it stands to play a crucial role in the global market, emphasizing both performance and sustainability. As domestic and international needs grow, China's commitment to innovation in titanium dioxide production will undoubtedly pave the way for a more sustainable industrial future.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025