10 月 . 20, 2024 12:28 Back to list

china titanium dioxide rutile

China's Titanium Dioxide Rutile An Overview of Production and Applications

Titanium dioxide (TiO2) is a widely used white pigment with remarkable properties, making it one of the most critical materials in various industries, including paints, coatings, plastics, and even food products. Among the different forms of titanium dioxide, rutile is particularly significant due to its superior optical and physical characteristics. With China emerging as the largest producer and consumer of titanium dioxide rutile, understanding its production processes, applications, and market dynamics is essential.

Production Processes

China dominates the global titanium dioxide market, leveraging its abundant titanium resources and advanced production techniques

. The primary methods for producing rutile from titanium ores include the sulfate process and the chloride process.1. Sulfate Process This traditional method involves treating titanium-bearing ores, like ilmenite, with sulfuric acid. The reaction produces titanium sulfate, which can then be hydrolyzed to produce titanium dioxide hydrate. After filtration, washing, and calcinating, rutile can be obtained. This process is known for producing lower quality TiO2 but is simpler and less costly than the chloride process.

2. Chloride Process This process is more sophisticated and results in high-purity rutile. It involves the conversion of titanium ores to titanium tetrachloride (TiCl4) using chlorine gas at high temperatures. The TiCl4 is then oxidized to yield rutile. Although capital-intensive, this method has gained popularity due to its ability to produce high-quality products that meet stringent regulatory standards.

Applications

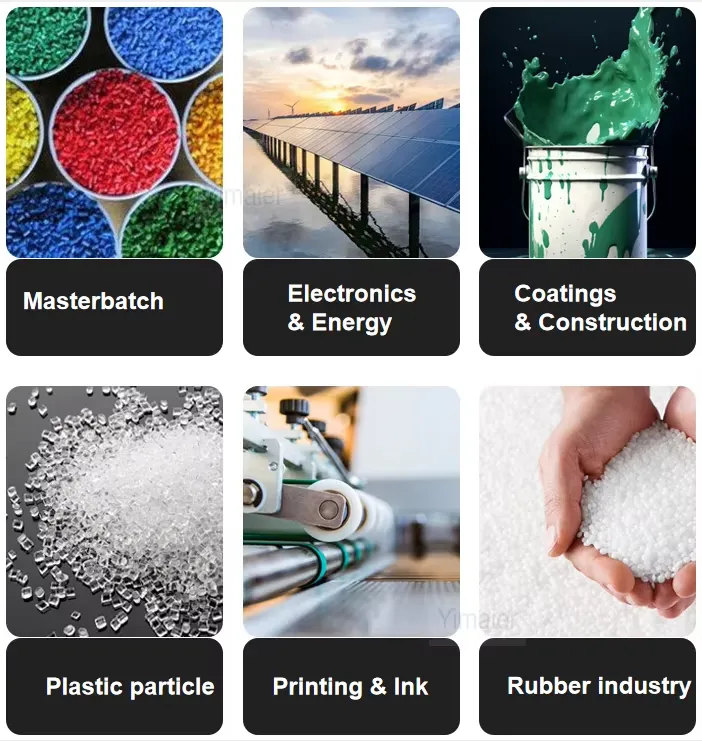

Rutile titanium dioxide is prized for its exceptional opacity, brightness, and resistance to discoloration, making it ideal for various applications

china titanium dioxide rutile

1. Coatings and Paints One of the primary uses of rutile TiO2 is in the coatings industry. Its high refractive index and excellent UV stability provide durable and vibrant finishes for both interior and exterior applications. Rutile pigments enhance hiding power and allow for the formulation of low-VOC (volatile organic compound) paints, aligning with global sustainability efforts.

2. Plastics and Polymers Rutile titanium dioxide is extensively used in plastic manufacturing to improve the mechanical properties and rigidity of products. It is added to polymers for enhanced weather resistance and to provide opacity, making it a common ingredient in products ranging from packaging materials to household goods.

3. Paper and Ink The paper industry utilizes rutile TiO2 to improve brightness and whiteness while enhancing the opacity of paper products. In inks, its use ensures rich color and fade resistance, making it an essential component in high-quality printing.

4. Cosmetics In the cosmetics sector, rutile TiO2 is used as a pigment in products like sunscreens and makeup due to its UV-filtering properties. It provides a lightweight feel and helps achieve a smooth application, which is essential for consumer satisfaction.

5. Food Applications Rutile titanium dioxide is occasionally used as a coloring agent in certain food products. However, the use of TiO2 in food has come under scrutiny, leading to increased regulation and reevaluation, particularly in markets like the European Union.

Market Dynamics

As of 2023, the demand for rutile titanium dioxide in China continues to rise, driven by various industrial sectors. The government’s focus on eco-friendly materials and sustainable practices is leading to innovations in TiO2 production, emphasizing the transition towards the chloride process. Moreover, the developing global market for electric vehicles and renewable energy technologies presents new opportunities for rutile titanium dioxide in applications such as batteries and solar panels.

In conclusion, China’s titanium dioxide rutile industry plays a crucial role in the global market, providing essential materials for numerous applications. As production techniques evolve and demand continues to grow, the industry will likely navigate challenges while contributing to more sustainable and innovative solutions across various sectors.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025