9 月 . 29, 2024 02:56 Back to list

China's Leading Titanium Powder Manufacturer for Advanced Material Solutions

The Landscape of Titanium Powder Production in China

As global demand for titanium continues to rise, particularly in industries like aerospace, automotive, and pharmaceuticals, China has emerged as a significant player in the production of titanium powder. The country is home to numerous factories dedicated to the manufacturing of this versatile material, leveraging advanced technology and vast resources to meet both domestic and international needs.

The Landscape of Titanium Powder Production in China

One of the factors contributing to the growth of titanium powder manufacturing in China is the government's support for the high-tech materials industry. Policies encouraging innovation and investment in advanced manufacturing technologies have spurred the establishment of numerous titanium powder factories. These facilities are often equipped with automated systems that optimize production workflow and minimize waste, further driving efficiency.

china titanium powder factory

Moreover, many Chinese titanium powder producers focus on research and development, collaborating with universities and research institutions to innovate new production methods. This commitment to R&D helps factories develop specialized powders with tailored properties, catering to specific requirements in the aerospace and medical industries. For example, the production of spherical titanium powder has gained attention for its role in additive manufacturing (3D printing), where precision and material performance are crucial.

In addition to catering to domestic markets, Chinese titanium powder factories also play a vital role in global supply chains. The competitive pricing and quality of Chinese titanium powder have made it an attractive option for international manufacturers. However, this expansion into global markets is not without challenges. Compliance with international standards and certifications is crucial for gaining market access. As such, many factories are working to obtain quality certifications to bolster their international credibility.

Sustainability is another important consideration for Taiwan's titanium powder factories. As environmental concerns become increasingly pivotal in industrial sectors, manufacturers are exploring greener production methods and actively seeking to minimize their carbon footprints. The implementation of recycling practices, such as reusing scrap powder, is also being prioritized to promote sustainable operations.

In summary, the titanium powder production landscape in China is characterized by advanced manufacturing techniques, strong governmental support, and a commitment to innovation. As the global demand for titanium continues to grow, Chinese factories are well-positioned to meet evolving market needs while contributing to sustainable practices in the industry. With ongoing advancements and a focus on quality, China's role in the titanium powder market is set to expand in the coming years.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

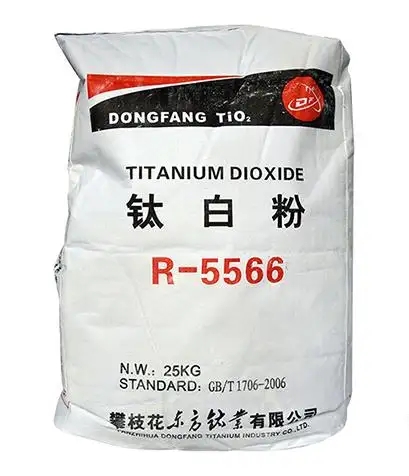

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025