10 月 . 19, 2024 14:59 Back to list

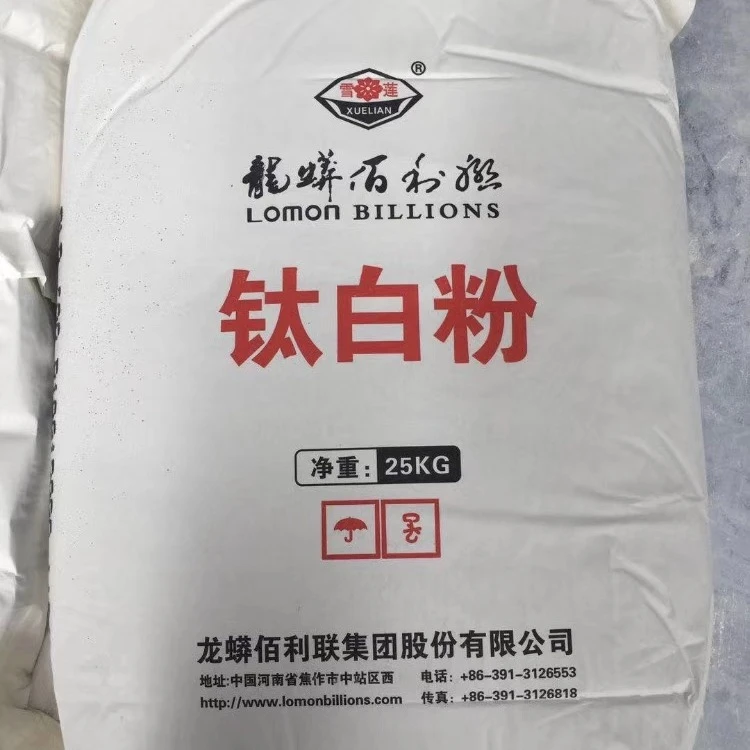

coating used titanium dioxide manufacturer

The Increasing Role of Coated Titanium Dioxide in Various Industries

Titanium dioxide (TiO2) has long been recognized as one of the most versatile and widely utilized materials in various industries, primarily due to its exceptional properties such as brightness, opacity, and UV resistance. The demand for higher efficiency and performance within these sectors has prompted innovations in the coating of titanium dioxide, leading to enhanced functionality and newer applications. In this article, we will explore the significance of coated titanium dioxide, its manufacturing processes, and its diverse applications.

The Importance of Coating

Coating titanium dioxide can serve multiple purposes. For example, coatings can enhance the material's photostability, improve its compatibility with other substances, and tailor its surface properties for specific applications. By employing various coating methods, manufacturers can create products with improved durability, reduced agglomeration, and optimized photocatalytic activity.

Coated titanium dioxide is particularly important in the paint and coatings industry. The addition of surface modifiers can improve dispersion within formulations, preventing clumping and ensuring uniformity. Furthermore, the enhanced stability of coated TiO2 allows for longer shelf lives and consistent performance, which is crucial for manufacturers aiming for high-quality end products.

Manufacturing Processes

The production of coated titanium dioxide typically involves two primary methods surface coating and composite formation. The surface coating method entails applying a thin layer of material on the surface of TiO2 particles, which can include silica, alumina, or other compounds. This process not only modifies the particle size distribution but also imparts specific properties that are desirable for particular applications.

The composite formation method involves combining titanium dioxide with other materials during the production process. One popular composite material is titanium dioxide embedded within polymer matrices, which offers advantages such as improved flexibility and reduced brittleness. Manufacturers often tailor these composites to meet the needs of specific industries, such as automotive, construction, or textiles.

Applications Across Industries

The applications of coated titanium dioxide span a wide range of industries

coating used titanium dioxide manufacturer

1. Paints and Coatings The primary use of TiO2 is in paints and coatings, where it provides exceptional opacity and whiteness. Coated titanium dioxide enhances durability and weather resistance, making it ideal for both interior and exterior applications.

2. Plastics In the plastic industry, coated TiO2 improves UV stability and prevents degradation from sunlight exposure. Its inclusion in polymers enhances color retention and product life.

3. Cosmetics Titanium dioxide is a common ingredient in sunscreens and cosmetics, serving as a broad-spectrum UV filter. Coating it can enhance its transparency in formulations, making it aesthetically pleasing while maintaining protective benefits.

4. Food Products Coated titanium dioxide is used in food packaging to increase the barrier properties and protect contents from UV light, thereby extending shelf life.

5. Photocatalysis The photocatalytic properties of titanium dioxide make it invaluable for environmental applications, such as air purification and self-cleaning surfaces. Coated TiO2 can enhance these properties by improving light absorption and catalytic activity.

The Future of Coated Titanium Dioxide

As industries continue to evolve, the demand for high-performance materials like coated titanium dioxide is expected to increase. Manufacturers are actively researching and developing new coating methodologies to create products that are not only effective but also environmentally friendly and sustainable.

Moreover, advancements in nanotechnology will likely lead to even more efficient forms of coated titanium dioxide. These innovations will potentially open doors to applications we have yet to explore, further solidifying TiO2’s position as an essential material across various sectors.

Conclusion

Coated titanium dioxide is a key player in many industries due to its enhanced properties and functionalities. As manufacturers continue to innovate in the coating processes and applications, the scope for titanium dioxide will only expand, suggesting a promising future for this remarkable material. From improving the durability of paints to enhancing the stability of cosmetic products, coated titanium dioxide serves as a pillar of modern manufacturing, with significant implications for common consumer goods and environmental sustainability alike.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025