8 月 . 13, 2024 01:26 Back to list

Exploring Global Production of Titanium Dioxide in Contemporary Manufacturing Facilities

The Role of Titanium Dioxide in Modern Industry

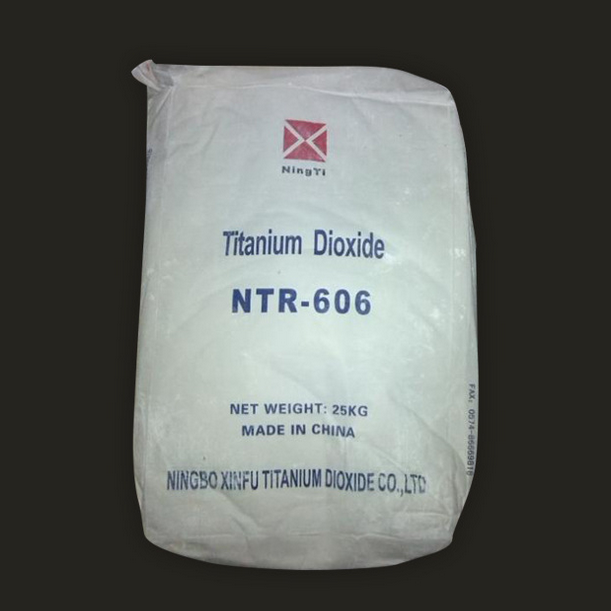

Titanium dioxide (TiO2) is a widely utilized compound in various industrial applications, particularly known for its exceptional opacity and bright white pigment properties. It plays a crucial role in several sectors, including coatings, plastics, food, and cosmetics. The global demand for titanium dioxide continues to increase, prompting the establishment of numerous factories worldwide dedicated to its production.

The Manufacturing Process

Titanium dioxide is primarily extracted from titanium ore, predominantly ilmenite and rutile. The production methods include the sulfate process and the chloride process. In the sulfate process, ilmenite is treated with sulfuric acid to produce titanium dioxide, alongside ferrous sulfate. This method, while effective, can generate significant waste byproducts.

Conversely, the chloride process involves the conversion of titanium ores into titanium tetrachloride, which is then oxidized to produce titanium dioxide. This method is favored for its efficiency and lower environmental impact compared to the sulfate process. Factories adopting the chloride process have been engineered to minimize emissions and waste.

Applications of Titanium Dioxide

The versatility of titanium dioxide makes it suitable for a myriad of applications. In the paint and coatings industry, TiO2 is prized for its excellent covering power, durability, and resistance to degradation from ultraviolet light. This makes it an essential component in both exterior and interior coatings.

In the plastics industry, TiO2 enhances the strength and weather resistance of products. It is commonly used in packaging materials, household goods, and automotive components. Given the trend toward sustainable materials, industries are increasingly looking for ways to incorporate bio-based or recycled components alongside titanium dioxide to create more environmentally friendly products.

r 5566 titanium dioxide factories

The food and cosmetics sectors also employ titanium dioxide, using it as a colorant and opacifying agent

. In these contexts, it is highly regarded for its safety and effectiveness. However, there has been ongoing debate regarding the safety of titanium dioxide in food products, leading to regulatory scrutiny in some regions.Environmental Considerations

As the number of titanium dioxide factories grows, so does the focus on the environmental impact of their operations. Producing titanium dioxide can lead to air and water pollution if not managed properly. Factories have begun to implement more sustainable practices, such as recycling waste materials and reducing energy consumption.

Moreover, there has been an increase in research aimed at finding alternative materials or processes that can either replace or reduce the reliance on titanium dioxide without compromising quality. Innovations in nanotechnology are also being explored, where smaller particles of TiO2 may provide similar benefits with less environmental burden.

Future Prospects

The future of titanium dioxide factories appears promising, particularly as industries shift toward more sustainable practices. The ongoing development of eco-friendly production techniques and responsible sourcing of titanium ores can help mitigate environmental issues associated with traditional manufacturing methods.

In conclusion, titanium dioxide remains a vital compound in numerous industries due to its unique properties. As production facilities evolve to adopt more sustainable practices, the responsible use of this material can ensure that it continues to support modern manufacturing while minimizing ecological impact. The commitment to environmentally safe methods will likely shape the future landscape of titanium dioxide production, balancing industrial needs with ecological stewardship.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025