8 月 . 12, 2024 14:16 Back to list

Exploring the Benefits of Titanium Dioxide in Rubber Manufacturing Processes for Enhanced Quality

Titanium Dioxide for Rubber Manufacturing Importance and Applications

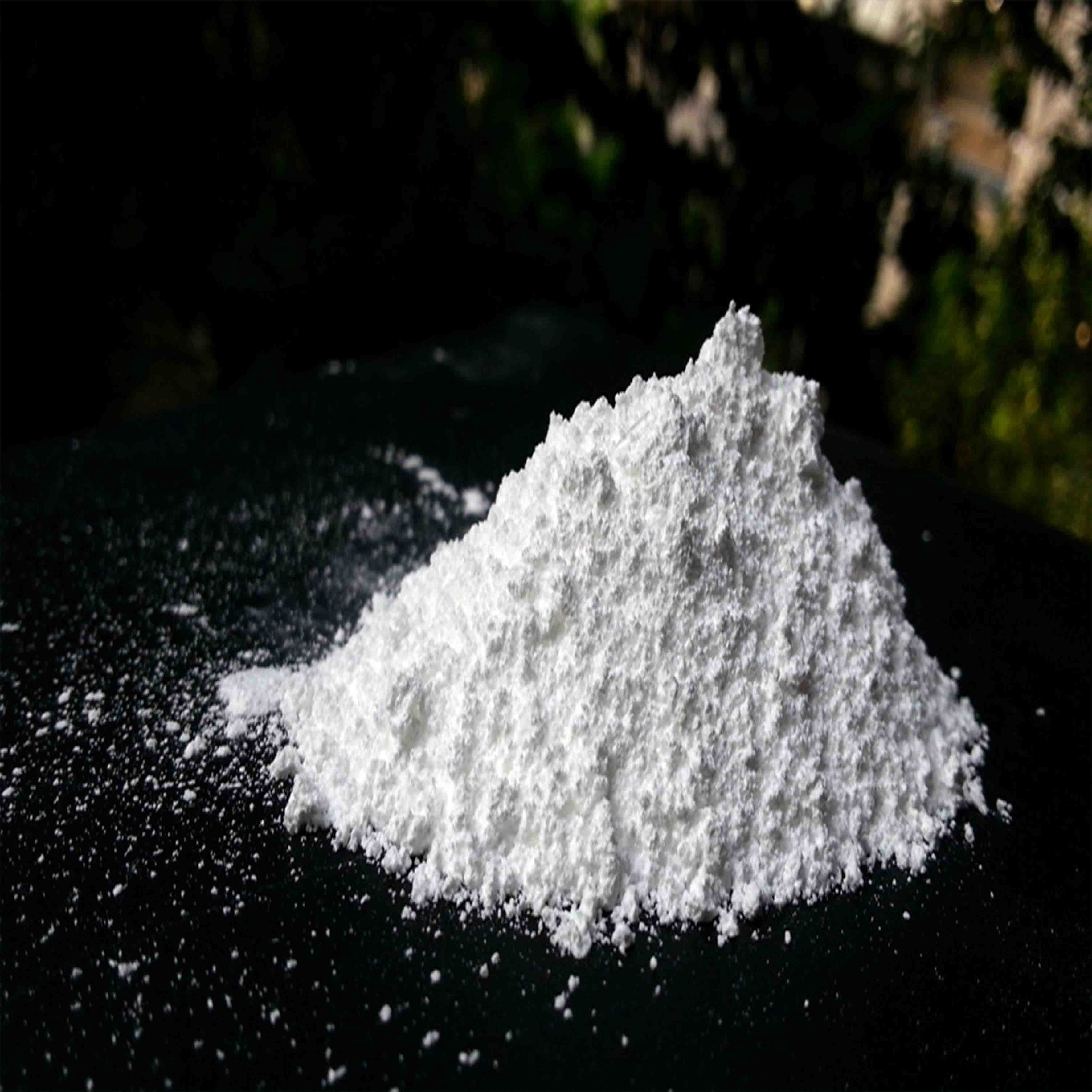

Titanium dioxide (TiO2) is a versatile compound widely used in various industries, with significant importance in rubber manufacturing

. This white pigment, renowned for its excellent opacity, brightness, and durability, plays a crucial role in enhancing the quality and performance of rubber products.In the rubber industry, titanium dioxide primarily serves as a filler and pigment. The inclusion of TiO2 improves the mechanical properties of the rubber, such as tensile strength and abrasion resistance. Additionally, the pigment helps in whitening the rubber compound, providing a clean and uniform appearance to the final product. This enhances the aesthetic appeal of rubber goods, making them more attractive to consumers.

One of the remarkable features of titanium dioxide is its ability to provide UV protection. Rubber products, especially those used outdoors, are susceptible to ultraviolet (UV) radiation, leading to degradation over time. The incorporation of TiO2 in rubber formulations effectively absorbs and scatters harmful UV rays, prolonging the lifespan of rubber products. This characteristic is particularly beneficial in manufacturing items like tires, automotive parts, and outdoor seals, which are constantly exposed to sunlight.

Moreover, titanium dioxide is known for its chemical stability. It is non-reactive, which means it does not alter the performance characteristics of rubber. This stability makes TiO2 an ideal choice for products that must endure harsh environmental conditions. Additionally, the compound is resistant to heat, enabling rubber products to maintain their integrity under high-temperature conditions, thus broadening their application range.

titanium dioxide for rubber factory

In terms of processing, titanium dioxide is relatively easy to incorporate into rubber formulations. It can be mixed with various types of rubber, including natural and synthetic variants, without significant alterations to the processing parameters. This adaptability makes TiO2 a preferred choice among rubber manufacturers who aim to optimize their production processes while ensuring superior product quality.

Another critical aspect of titanium dioxide's role in the rubber industry is its contribution to sustainability. With growing environmental concerns and an increasing demand for eco-friendly products, using TiO2 can help manufacturers meet sustainability goals. Titanium dioxide is derived from abundant natural resources, and its production process has become increasingly efficient, minimizing waste and energy consumption. Furthermore, rubber products containing TiO2 can be recycled and reused, thus contributing to a circular economy.

However, it is essential to consider the source and form of titanium dioxide used in manufacturing. Not all forms of TiO2 are created equal; the particle size and surface treatment can significantly influence the performance in rubber applications. Manufacturers typically opt for high-quality, surface-treated TiO2, enhancing dispersibility and compatibility within the rubber matrix.

In conclusion, titanium dioxide plays a pivotal role in the rubber manufacturing industry, contributing to improved mechanical properties, UV protection, chemical stability, and overall product quality. As manufacturers continue to seek ways to enhance their products while adhering to sustainability principles, the relevance of TiO2 in rubber applications is expected to grow. Embracing advancements in TiO2 technology will not only help rubber manufacturers enhance their competitive edge but also meet the ever-evolving demands of environmentally conscious consumers. With its multifaceted benefits, titanium dioxide remains an indispensable component in the realm of rubber manufacturing.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025