8 月 . 09, 2024 08:10 Back to list

Exploring the Current Market Trends and Pricing for Bulk Titanium Dioxide Purchases

Understanding the Cost of Wholesale Titanium Dioxide

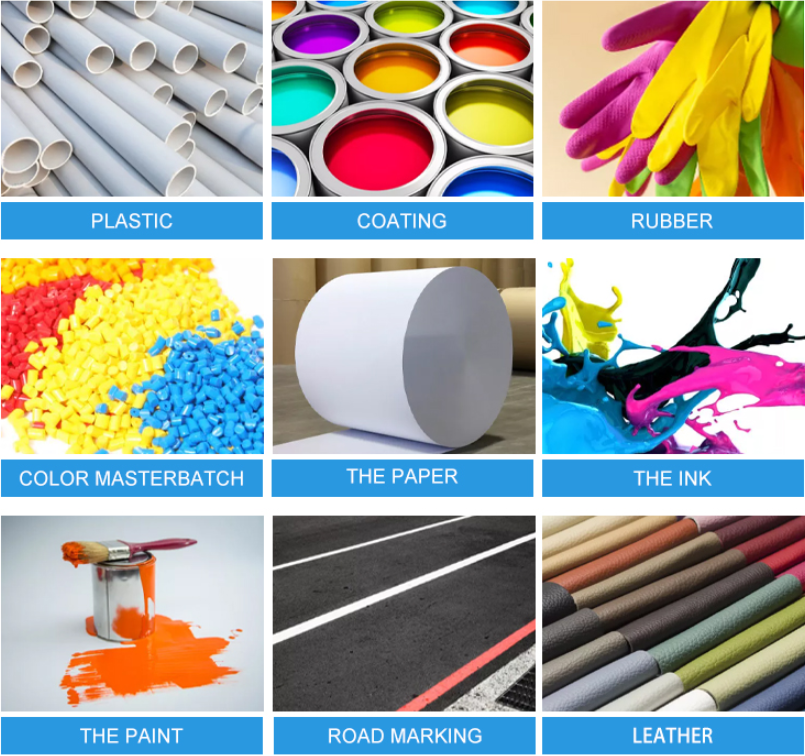

Titanium dioxide (TiO2) is a versatile pigment widely used in various industries, including paints, coatings, plastics, cosmetics, and food. Its exceptional brightness, high refractive index, and UV resistance make it an ideal choice for manufacturers looking to enhance the aesthetic and functional qualities of their products. However, one crucial factor that businesses must consider when sourcing titanium dioxide is its cost, particularly in the wholesale market.

Factors Influencing Titanium Dioxide Prices

1. Raw Material Costs The primary source of titanium dioxide is titanium ore, primarily ilmenite and rutile. Fluctuations in the prices of these raw materials directly impact the overall cost of titanium dioxide. Factors such as mining regulations, geological availability, and environmental considerations can lead to variations in material costs.

2. Production Processes Titanium dioxide can be produced through two main processes the sulfate process and the chloride process. The sulfate process is generally more cost-effective, utilizing less expensive raw materials. However, it also generates more waste, leading to higher environmental compliance costs. The chloride process, while more sustainable, is costlier due to the advanced technologies and equipment required. The choice between these methods, depending on the producer, affects the wholesale pricing of titanium dioxide.

3. Demand and Market Trends The demand for titanium dioxide is influenced by several market trends, such as the growth of the construction industry, rising consumer awareness regarding product quality, and the expanding market for eco-friendly products. Fluctuating demand can lead to price volatility, particularly as manufacturers adjust their production levels in response to market needs.

4. Geopolitical Factors Trade relations and geopolitical tensions can significantly affect the supply chain of titanium dioxide. Countries that are major producers of titanium ore, such as Australia, South Africa, and Canada, may face export restrictions or tariffs that can squeeze supply and elevate costs. Additionally, the COVID-19 pandemic has exposed vulnerabilities in global supply chains, further influencing price dynamics.

wholesale titanium dioxide cost

5. Technological Advancements Ongoing innovations in production technologies can impact the cost-efficiency of titanium dioxide manufacturing. Improved methods that reduce energy consumption, minimize waste, and enhance product quality can result in lower wholesale costs over time. Companies that invest in research and development to harness these advancements may offer competitive pricing in the wholesale market.

Wholesale Market Dynamics

In the wholesale market, buyers are often looking for competitive pricing, consistent supply, and quality assurance. Bulk purchasing typically allows for cost savings, but buyers must also consider the reliability of their suppliers. It's essential for businesses to establish relationships with reputable manufacturers who can provide high-quality titanium dioxide while offering favorable pricing structures.

Moreover, it is crucial for companies to stay updated with market trends and price fluctuations. By analyzing market reports, industry forecasts, and supplier pricing strategies, companies can make informed purchasing decisions that optimize their operational costs.

Conclusion

Navigating the wholesale titanium dioxide market requires a deep understanding of the factors that influence its cost. From raw material prices to production processes and market demand, businesses must remain vigilant and adaptive. As the industry evolves, those who leverage strategic purchasing, maintain quality standards, and stay informed will be best positioned to thrive in the competitive landscape of titanium dioxide sourcing. Ultimately, a keen focus on cost management will empower businesses to deliver superior products while maximizing their profit margins.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025