8 月 . 12, 2024 20:56 Back to list

Exploring the Innovations and Technologies in R996 Titanium Dioxide Production Facilities Today

The R996 TiO2 Factory Innovations and Sustainability in Titanium Dioxide Production

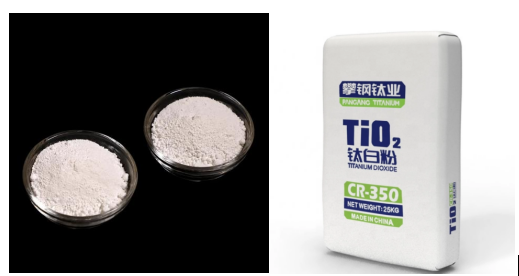

The R996 titanium dioxide (TiO2) factory is a remarkable facility that has become a beacon of innovation within the global TiO2 industry. As one of the leading producers of titanium dioxide, the factory exemplifies the integration of advanced technologies and sustainable practices in chemical manufacturing. With the increasing demand for high-quality TiO2, driven by its wide applications in paints, plastics, coatings, and cosmetics, the R996 factory stands out not only for its production capabilities but also for its commitment to environmental stewardship.

The R996 TiO2 Factory Innovations and Sustainability in Titanium Dioxide Production

Sustainability is at the heart of the R996 factory's operations. The facility has implemented a series of initiatives aimed at minimizing its carbon footprint and addressing the challenges posed by climate change. For instance, the factory is committed to energy efficiency, employing renewable energy sources where possible. This not only reduces operational costs but also contributes to a more sustainable production model. By utilizing solar panels and other renewable technologies, the R996 factory is leading the way in demonstrating how traditional manufacturing can evolve to meet modern environmental standards.

r996 tio2 factory

In addition to energy efficiency, the R996 factory emphasizes waste reduction and recycling. Closed-loop systems are employed to ensure that any waste generated in the production process is reused or repurposed. This not only minimizes landfill contributions but also maximizes resource utilization, aligning with the principles of a circular economy. Furthermore, the facility is continuously exploring innovative methods to further reduce its environmental impact, including the development of biodegradable TiO2 products and the exploration of alternative raw materials.

Quality control is another cornerstone of the R996 TiO2 factory's operations. The facility boasts a state-of-the-art laboratory equipped with advanced analytical instruments to ensure that every batch of titanium dioxide meets the industry's high standards. Rigorous testing protocols are in place to assess the pigment's performance, including aspects such as opacity, whiteness, and particle size distribution. This focus on quality not only reinforces customer trust but also enhances the factory's reputation in the competitive TiO2 market.

Collaboration is also crucial to the R996 factory’s success. The facility works closely with research institutions, industry partners, and customers to drive innovation and develop new applications for titanium dioxide. By fostering a culture of collaboration, the R996 factory positions itself at the forefront of technological advancements, enhancing both product performance and sustainability.

In summary, the R996 titanium dioxide factory represents a forward-thinking approach to chemical manufacturing. Through the adoption of modern production technologies, a commitment to sustainability, and a relentless focus on quality, the factory not only meets the growing demands of the TiO2 market but also sets a standard for responsible manufacturing practices. As the world increasingly values environmental stewardship and sustainable development, the R996 factory is poised to lead the way, proving that industrial growth and ecological responsibility can go hand in hand.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025