8 月 . 13, 2024 16:30 Back to list

Exploring the Production Processes and Innovations in Titanium Dioxide Pigment Manufacturing Facilities

The Role of Titanium Dioxide in the Pigment Industry

Titanium dioxide, often referred to as TiO2, is a highly valued white pigment employed across various industries for its exceptional properties and versatility. As one of the most widely used white pigments globally, titanium dioxide is praised for its excellent opacity, brightness, and durability. Its applications span diverse sectors, including coatings, plastics, paper, and cosmetics, making it an integral component of modern manufacturing.

The production of titanium dioxide primarily occurs through two processes the sulfate process and the chloride process. Each method has its own merits and challenges, leading to variations in particle size, morphology, and purity. The sulfate process involves digesting ilmenite ore with sulfuric acid, while the chloride process uses titanium tetrachloride derived from rutile or anatase ores. Factories dedicated to producing titanium dioxide utilize advanced technologies to ensure the efficiency and environmental sustainability of these processes.

The Role of Titanium Dioxide in the Pigment Industry

The global demand for titanium dioxide continues to rise, driven by the growth of the construction and automotive industries, as well as the increasing popularity of consumer goods like paints and cosmetics. As countries invest in infrastructure development and home renovations, the need for high-quality pigments that offer durability and aesthetic appeal has become paramount. Furthermore, the trend towards sustainability has seen a surge in demand for eco-friendly coatings and substances, positioning titanium dioxide as a frontrunner in meeting these needs.

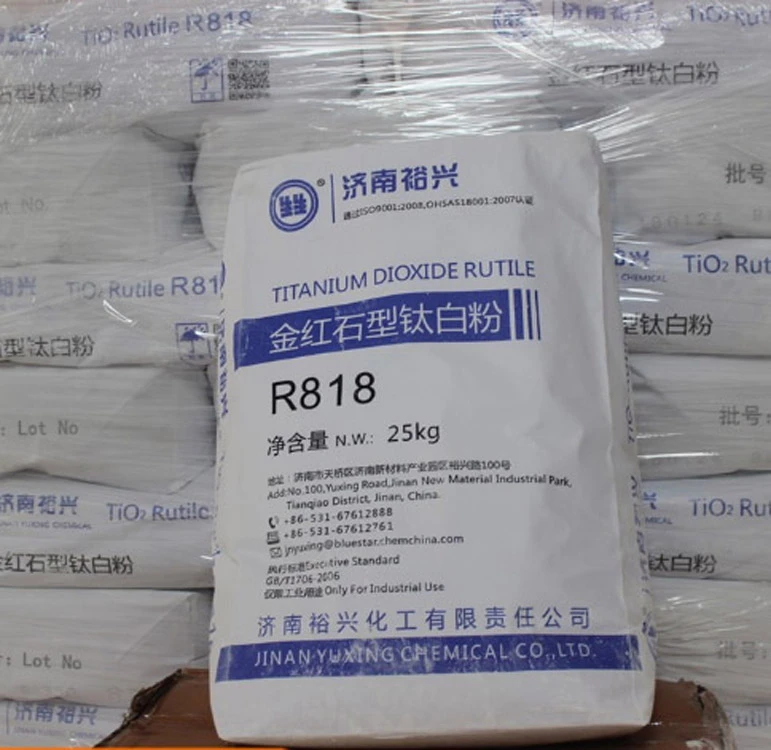

pigment titanium dioxide factories

However, the production of titanium dioxide is not without its challenges. Environmental regulations are becoming increasingly stringent, prompting factories to adopt cleaner production methods. The sulfate process, for instance, generates significant waste, including gypsum, which poses disposal challenges. In response, many manufacturers are exploring alternative feedstocks and recycling processes to minimize their ecological footprint. The chloride process, while more efficient, also requires careful management of by-products to mitigate adverse environmental impacts.

Moreover, the titanium dioxide industry plays a crucial role in the global economy. Major producers of titanium dioxide include companies in the United States, Europe, and Asia, with significant players like Chemours, Tronox, and Huntsman. These companies invest heavily in research and development to innovate new applications and improve existing formulations, ensuring that titanium dioxide remains relevant in an ever-evolving market.

With the rise of nanotechnology, the use of nano-sized titanium dioxide particles has opened up new avenues for application, particularly in sunscreens and cosmetics, where increased skin compatibility and UV protection are paramount. The ongoing research into the benefits of titanium dioxide nanoparticles is likely to expand its market further, making it indispensable in new consumer product formulations.

In conclusion, titanium dioxide remains a cornerstone of the pigment industry, delivering unmatched performance and versatility across various applications. As factories continue to evolve and adapt to new environmental standards and market demands, the significance of titanium dioxide is expected to grow, underscoring its importance to both industry and consumers alike. With ongoing innovations and a commitment to sustainability, the future of titanium dioxide in the pigment sector appears promising.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025