7 月 . 28, 2024 18:05 Back to list

Gravimetric Analysis Techniques for Titanium Dioxide Production in Industrial Settings and Their Applications

Gravimetric Analysis of Titanium Dioxide A Factory Perspective

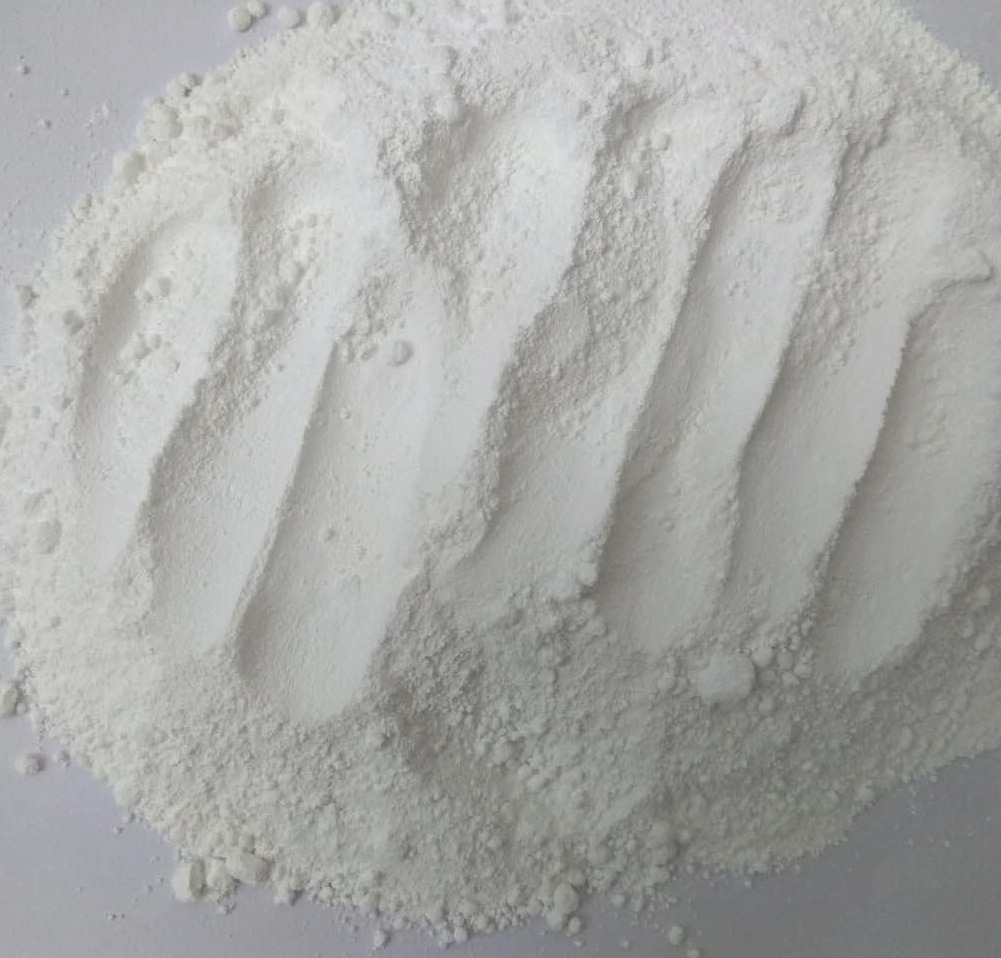

Titanium dioxide (TiO2) is a versatile and widely used compound, primarily recognized for its applications in various industries such as paints, coatings, plastics, and cosmetics. One of the key aspects of ensuring the quality and performance of titanium dioxide products is the precise determination of its concentration and purity. Gravimetric analysis has emerged as a pivotal method in this regard, particularly in a factory setting where consistent quality control is paramount.

Gravimetric analysis involves measuring the mass of a substance to determine its quantity, with a high degree of accuracy and precision. In the context of titanium dioxide production, this technique is particularly beneficial for assessing the purity of the TiO2 produced and understanding its physical properties. The process typically involves several steps, including sample preparation, precipitation, filtration, drying, and weighing.

Sample Preparation

In the factory environment, the first step in gravimetric analysis is preparing a representative sample of titanium dioxide. This involves careful sampling techniques to ensure that the sample reflects the bulk material accurately. Samples may be taken from various points in the production line to ensure consistency across different batches. Once collected, the samples are often dried and ground to attain a homogeneous powder for analysis.

Precipitation and Filtration

The next phase involves dissolving the titanium dioxide in an appropriate solvent to separate it from impurities and other materials. Following dissolution, a precipitating agent is added to form a stable precipitate of titanium compounds, typically titanates. This solid precipitate can then be isolated by filtration, using specialized filter media that maximize recovery and minimize material loss. In a factory setting, automation may play a role in enhancing the efficiency of this step.

titanium dioxide gravimetric analysis factory

Drying and Weighing

After filtration, the precipitate is thoroughly washed to remove any adhering impurities and is subsequently dried in an oven or a specialized drying chamber. The importance of this step cannot be overstated, as any residual moisture can lead to inaccurate mass measurements, which would ultimately undermine the analysis. Once dried, the precipitate is carefully weighed using high-precision balances that are routinely calibrated to ensure accuracy.

Quality Control

The gravimetric analysis of titanium dioxide not only serves to quantify the material but also plays a crucial role in quality control within the factory. By regularly employing this analytical method, manufacturers can monitor variations in their production processes, identify any disturbances that may lead to impurities, and ensure that their final product meets the required specifications. This continuous feedback loop is essential for maintaining high standards of quality and safety in products that utilize titanium dioxide.

Conclusion

Gravimetric analysis is an integral component of titanium dioxide production in a factory environment. Through meticulous sample preparation, specialized precipitation and filtration techniques, and precise weighing methods, manufacturers can ensure the purity and quality of their TiO2 products. As industries increasingly demand higher quality materials, the importance of robust analytical methods like gravimetric analysis will continue to grow, solidifying its role as a cornerstone of quality assurance in titanium dioxide manufacturing. By investing in state-of-the-art analytical techniques and maintaining a strong focus on quality control, factories can not only enhance their product offerings but also gain a competitive edge in the marketplace.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025