8 月 . 11, 2024 10:06 Back to list

High-Quality Titanium Dioxide Solutions for Plastic Manufacturers to Enhance Product Performance and Aesthetics

Titanium Dioxide for Plastic Manufacturers Elevating Quality and Performance

Titanium dioxide (TiO2) is a widely recognized white pigment that plays a pivotal role in various industries, especially in plastics manufacturing. Its exceptional properties, including high opacity, brightness, and resistance to UV light, make it an invaluable additive for achieving superior quality in plastic products. As the demand for durable, aesthetically pleasing, and environmentally friendly materials continues to grow, titanium dioxide has emerged as a key component for plastic manufacturers seeking to enhance the performance and visual appeal of their products.

Enhancing Aesthetics and Opacity

One of the primary reasons for using titanium dioxide in plastic formulations is its outstanding opacity. It effectively scatters light, providing excellent coverage and hiding power, which is particularly beneficial for creating vibrant and uniform colors in plastic products. This is critical in applications such as packaging, automotive interiors, and consumer electronics, where visual appeal is paramount. The ability to produce bright white plastics also allows manufacturers to create sophisticated designs while maintaining color integrity.

Furthermore, titanium dioxide contributes to the longevity of plastic products by improving their color stability. Plastics without adequate pigmentation can become discolored over time, which may lead to decreased consumer appeal. By incorporating TiO2, manufacturers can ensure that their products not only look good upon production but also retain their visual quality over time.

UV Resistance and Durability

Titanium dioxide also exhibits excellent UV resistance, making it an essential additive for outdoor plastic applications. Plastics exposed to sunlight can degrade, leading to brittleness, fading, and loss of mechanical strength. TiO2 acts as a UV filter, protecting plastics from the harmful effects of ultraviolet radiation. This property is particularly crucial for products like outdoor furniture, automotive parts, and construction materials, where exposure to the elements is inevitable.

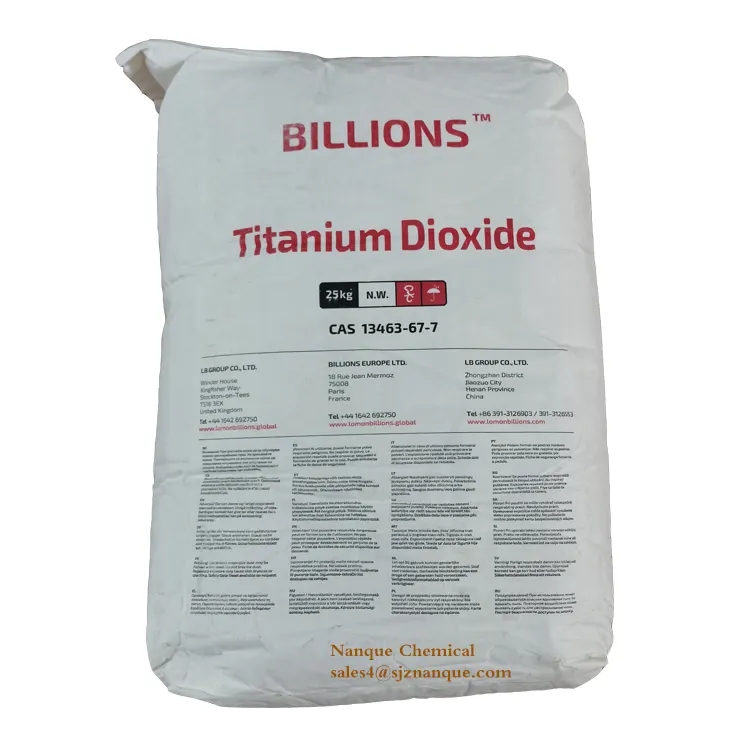

titanium dioxide for plastic manufacturer

Additionally, the incorporation of titanium dioxide can enhance the mechanical properties of plastics, including impact resistance and tensile strength. By reinforcing the polymer matrix, TiO2 helps create more durable products that can withstand rigorous use and environmental stressors. This attribute is especially beneficial in sectors such as automotive and construction, where the performance and longevity of products are critical to customer satisfaction.

Eco-Friendly Alternatives

As the global market leans towards sustainable practices, the eco-friendliness of titanium dioxide has also garnered attention. Derived from abundant natural resources, TiO2 poses minimal environmental risks compared to some synthetic pigments. Moreover, the increasing adoption of bio-based plastics is complemented by the use of titanium dioxide, which can enhance the properties of these materials without compromising their sustainability objectives.

Plastic manufacturers are now more inclined to seek environmentally benign solutions that align with regulatory standards and consumer expectations. TiO2 not only fulfills the requirement for performance and aesthetics but also supports the industry's shift toward greener alternatives, contributing to reduced environmental impact.

Conclusion

In conclusion, titanium dioxide is a versatile and essential ingredient for plastic manufacturers aiming to enhance product quality and performance. Its exceptional properties—ranging from superior opacity and UV resistance to improved mechanical strength and eco-friendliness—make it a valuable additive in various applications. As the global market continues to evolve, embracing innovative materials like titanium dioxide will be key to producing high-quality plastics that meet the demands of consumers and regulatory bodies alike. With its ability to elevate both aesthetics and durability, TiO2 will undoubtedly remain a cornerstone in the plastic manufacturing industry for years to come.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025