7 月 . 25, 2024 09:00 Back to list

Leading Manufacturers of Synthetic Titanium Dioxide for Various Industrial Applications and Markets Today

Synthetic Titanium Dioxide Manufacturers An Overview

Synthetic titanium dioxide (TiO2) is a widely used industrial material due to its excellent properties such as high refractive index, UV resistance, and durability. As a white pigment, it plays a crucial role in various applications, including paints, coatings, plastics, cosmetics, and food products. The demand for synthetic titanium dioxide continues to grow, driven by its versatility and the expanding markets for building materials, automotive components, and consumer goods.

The process of manufacturing synthetic titanium dioxide typically involves two main methods the sulfate process and the chloride process

. Each method has its advantages and characteristics, which influence the final product's quality and cost.1. Sulfate Process This traditional method involves the reaction of titanium ores (e.g., ilmenite) with sulfuric acid. The process generates a titanium sulfate solution, which is subsequently hydrolyzed to yield titanium dioxide hydrate. Following filtration and drying, the hydrate is calcined to produce the final TiO2 product. The sulfate process is known for being less capital-intensive; however, it can create larger volumes of waste and requires careful management of by-products.

2. Chloride Process The chloride process is more modern and is often preferred for producing high-purity titanium dioxide. In this method, titanium ores are reacted with chlorine gas to produce titanium tetrachloride (TiCl4), which is then oxidized at high temperatures in the presence of oxygen to yield titanium dioxide. One of the advantages of the chloride process is that it produces less waste and results in a cleaner product, making it more environmentally friendly. However, it requires significant capital investment, making it less accessible for some manufacturers.

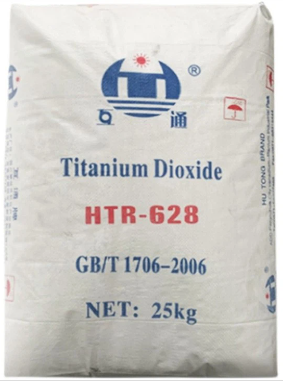

synthetic titanium dioxide manufacturers

Leading synthetic titanium dioxide manufacturers employ both processes, optimizing their operations to enhance efficiency, reduce costs, and meet environmental regulations. Major players in the industry include companies such as Chemours, Tronox, and Huntsman Corporation, each with a significant share of the global market. These companies invest heavily in research and development, focusing on improving production methods and developing innovative applications for titanium dioxide.

One of the important trends in the synthetic titanium dioxide market is the increasing emphasis on sustainability. Manufacturers are exploring ways to minimize their environmental impact by adopting cleaner production techniques, recycling waste products, and utilizing renewable energy sources. Additionally, as industries strive for greener products, the demand for eco-friendly high-performance coatings and paints that utilize sustainable titanium dioxide has surged.

Apart from sustainability, the market for synthetic titanium dioxide is driven by various end-use industries. In the construction sector, the material's excellent opacity and weather resistance make it ideal for paints and coatings that protect buildings from environmental degradation. In the automotive industry, synthetic TiO2 serves as an essential component in high-quality coatings, providing both aesthetic appeal and durability. Moreover, the cosmetics and personal care sectors leverage titanium dioxide for its UV filtering properties, enhancing the effectiveness of sunscreens and other skincare products.

In conclusion, the synthetic titanium dioxide manufacturing industry plays a pivotal role in multiple sectors, driven by innovation, demand for sustainability, and continuous growth. As manufacturers strive to balance productivity with environmental responsibility, the future of synthetic titanium dioxide looks promising, opening up new avenues for application and expanding its footprint in global markets. The ongoing advancements in manufacturing technology and increased focus on sustainability will likely define the trajectory of synthetic titanium dioxide and its manufacturers in the years to come.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025