9 月 . 16, 2024 11:21 Back to list

Lithopone Powder Factory - High-Quality Lithopone Production

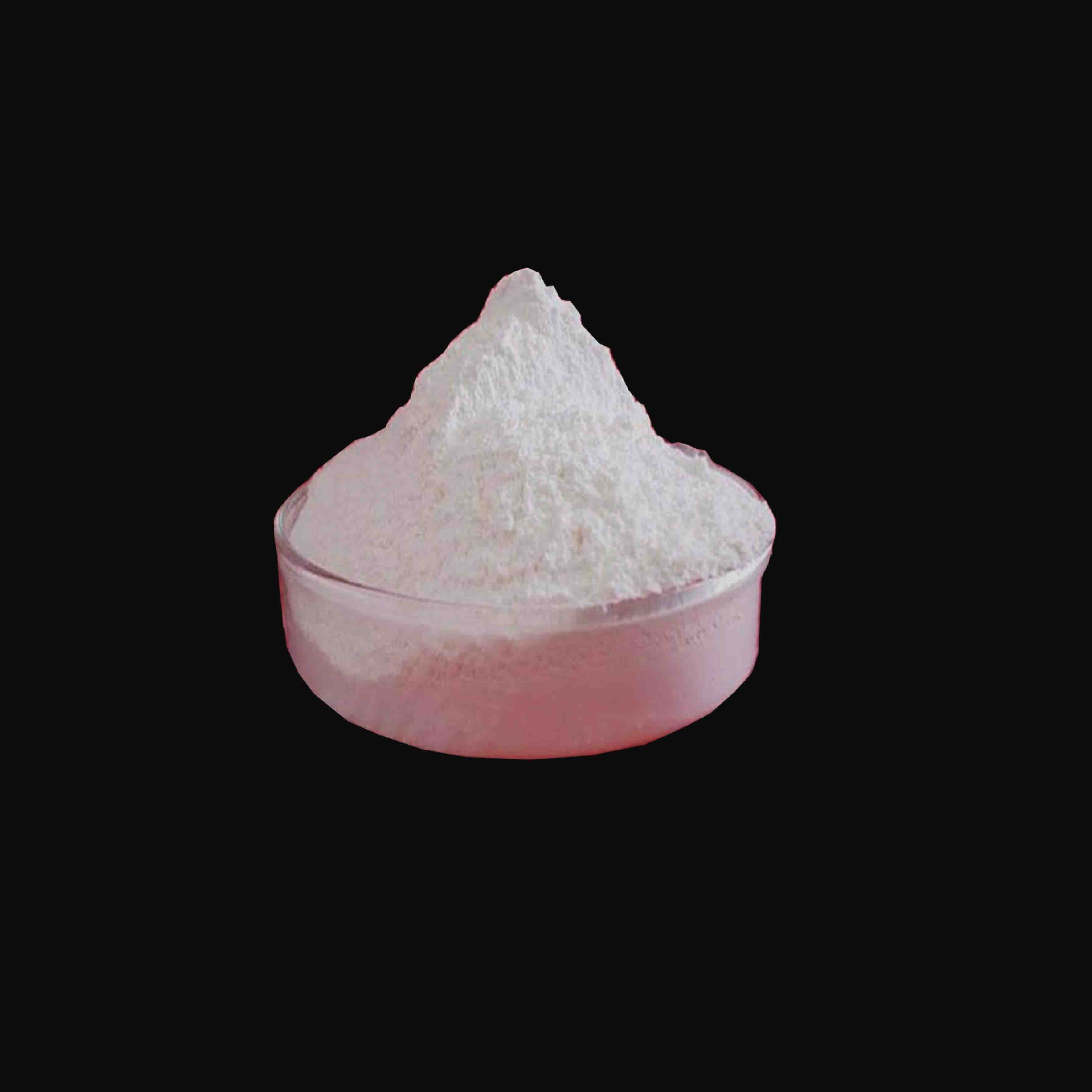

The Lithopone Powder Factory A Beacon of Quality Products

The lithopone powder factory represents a vital segment of the industrial landscape, specializing in the production of one of the most versatile white pigments in the world. Lithopone, a composite of zinc sulfide and barium sulfate, is renowned for its opacity, stability, and non-toxicity. Its applications span various industries, from paints and coatings to plastics and cosmetics. This article delves into the significance of lithopone powder production, the factory’s operations, and its impact on the market.

At the heart of the lithopone powder factory lies a sophisticated manufacturing process that emphasizes quality and efficiency

. The production begins with sourcing high-grade zinc and barium mineral ores, which are scrutinized for purity and composition. Skilled technicians oversee the blending of these raw materials in precise ratios, ensuring optimal results. The mixture undergoes a series of chemical reactions, culminating in the formation of lithopone powder. Advanced milling and sieving processes follow to achieve the desired granularity and consistency.Environmental sustainability is a core principle of modern lithopone powder factories. The production involves careful waste management practices to minimize the ecological footprint. Many factories have adopted closed-loop systems that recycle water and minimize emissions. Furthermore, advancements in technology have led to the development of eco-friendly alternatives for energy consumption, making lithopone production less taxing on natural resources.

lithopone powder factory

As industries evolve, so too do the applications of lithopone powder. In the paint industry, for instance, it serves as an essential whitening agent that enhances durability and resistance to ultraviolet light. Its use in plastics not only improves aesthetic appeal but also contributes to the material's strength and longevity. Even in cosmetics, lithopone is employed due to its safe and hypoallergenic properties. As consumers increasingly seek non-toxic and environmentally friendly products, the demand for lithopone continues to grow.

The lithopone powder factory plays a pivotal role in meeting this demand. By maintaining rigorous quality control standards, these factories ensure that their products meet international specifications, making them competitive in the global market. Collaboration with research and development teams helps in innovating new formulations and improving existing ones, thereby addressing the dynamic needs of diverse industries.

In conclusion, the lithopone powder factory stands as a testament to modern manufacturing excellence. By focusing on quality, sustainability, and innovation, it not only contributes to various sectors but also champions the cause of environmentally responsible production. As industries continue to evolve, the lithopone powder factory will undoubtedly remain a cornerstone of progress, providing high-quality materials that foster creativity and growth across multiple applications.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025