10 月 . 16, 2024 22:21 Back to list

lithopone b311 b301 quotes factory

Understanding Lithopone Insights into B311 and B301 Grades

Lithopone, a pigment widely used in various applications, is primarily a mixture of zinc sulfide and barium sulfate. Known for its excellent opacity, brightness, and UV resistance, lithopone finds its place in paints, coatings, plastics, and even in paper products. The two notable grades of lithopone, B311 and B301, have distinct characteristics that cater to different industry needs.

Lithopone B311 A Versatile Choice

Lithopone B311 is recognized for its superior performance. With a high pigment concentration, it offers exceptional opacity, making it a preferred choice for applications where coverage and brightness are paramount. This grade is particularly suited for use in high-quality paints and coatings, where aesthetic appeal is a significant factor. Due to its fine particle size, B311 provides a smooth finish and enhances the durability of the final product. Additionally, its compatibility with various resin systems makes it a versatile option for manufacturers.

B311 is favored for exterior applications due to its resistance to light and color fading. This quality not only ensures longevity but also preserves the vividness of colors used in decorative paints. Furthermore, the low oil absorption of B311 allows for easy formulation with other chemicals, making it a manufacturer-friendly option. The demand for B311 continues to rise as industries prioritize high-performance materials that meet consumer expectations for quality and longevity.

Lithopone B301 Economic and Efficient

lithopone b311 b301 quotes factory

On the other hand, Lithopone B301 stands out as a cost-effective alternative. While it might not match the opacity of B311, B301 offers satisfactory performance for budget-sensitive applications. This grade is ideal for industries looking to reduce costs without significantly compromising on quality. B301 is often utilized in lower-end paints, primers, and fillers, where high opacity is less critical.

Manufacturers appreciate B301 for its excellent dispersibility in a variety of systems, making it suitable for a wide range of applications, including plastics and rubber products. Its balanced properties allow for efficient production processes while still delivering an adequate level of performance for everyday applications.

Conclusion Making the Right Choice

When selecting between lithopone grades, manufacturers must consider their specific requirements and the intended use of the final product. While B311 offers premium performance, B301 serves as an economical choice that meets basic needs. The choice ultimately depends on factors such as budget, performance standards, and desired application.

In conclusion, lithopone grades B311 and B301 play crucial roles in the pigment industry, each addressing unique aspects of product performance and cost-effectiveness. As industries evolve and focus on sustainability and efficiency, understanding the characteristics of these lithopone grades will help in making informed decisions that align with both market needs and consumer expectations.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

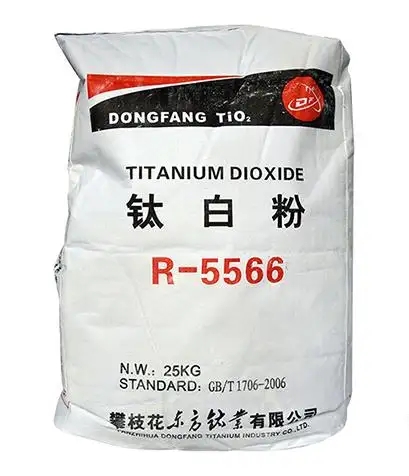

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025