7 月 . 26, 2024 00:14 Back to list

Manufacturers Specializing in Erythrosine and Titanium Dioxide for Various Industrial Applications

Erythrosine and Titanium Dioxide An Overview of Their Manufacturing and Applications

Erythrosine, a synthetic red dye, and titanium dioxide, a widely used white pigment, are two important compounds prevalent in various industries, including food, cosmetics, pharmaceuticals, and paints. As manufacturers of these substances continue to innovate and expand their applications, understanding their properties, manufacturing processes, and regulatory frameworks becomes crucial.

Erythrosine Characteristics and Applications

Erythrosine, also known as E127, is an iodinated dye derived from fluorescein. It produces a vibrant cherry-red color and is commonly used in food products, particularly in candies, desserts, and beverages. Additionally, erythrosine finds its place in cosmetics and pharmacological applications due to its stable and bright hue.

The manufacturing process of erythrosine typically involves the synthesis of fluorescein followed by an iodination reaction. This process is conducted under controlled conditions to ensure the purity and quality of the dye. Manufacturers must adhere to stringent regulations set by food safety authorities, such as the FDA in the United States and the European Food Safety Authority (EFSA) in Europe, which monitor the acceptable daily intake levels and ensure that erythrosine does not pose health risks to consumers.

One challenge faced by manufacturers of erythrosine is the growing demand for natural alternatives in food coloring. As consumers become more health-conscious and aware of synthetic additives, there is an increasing preference for natural colors sourced from fruits and vegetables. This shift encourages erythrosine manufacturers to innovate and explore more sustainable production methods, while maintaining the quality and cost-effectiveness of their products.

Titanium Dioxide Properties and Uses

erythrosine and titanium dioxide manufacturer

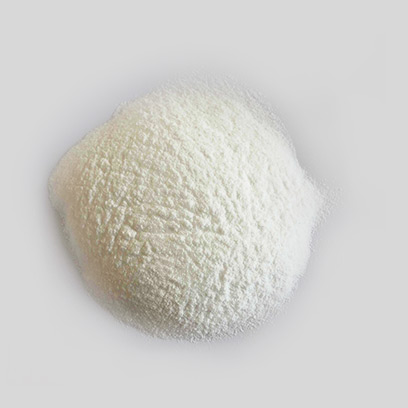

Titanium dioxide (TiO2) is a naturally occurring mineral primarily used as a white pigment due to its excellent coverage, brightness, and UV resistance. It is a vital component in various applications, including paints, coatings, plastics, and cosmetics. The demand for titanium dioxide has surged over the years, driven by the growth in construction, automotive, and packaging industries.

The production of titanium dioxide typically involves two main processes the sulfate process and the chloride process. The sulfate process utilizes titanium-bearing ores treated with sulfuric acid, while the chloride process involves the reaction of titanium ores with chlorine at high temperatures. Both processes yield high-purity titanium dioxide, but the chloride process is often preferred for its lower environmental impact and higher yield of the final product.

Despite its significant benefits, titanium dioxide has recently faced scrutiny over health concerns, particularly regarding its inhalation as a fine particulate in certain applications. Regulatory agencies have classified it as possibly carcinogenic when inhaled in high concentrations. This has prompted manufacturers to invest in research and development to discover safer alternatives and to implement better safety measures during production.

The Future of Erythrosine and Titanium Dioxide Manufacturing

As the landscape of consumer preferences and regulations continues to evolve, the manufacturers of erythrosine and titanium dioxide must adapt to maintain their market competitiveness. Innovations in sourcing raw materials sustainably, improving production efficiency, and creating safer formulations are essential strategies for navigating these challenges.

Moreover, collaboration between manufacturers, regulatory bodies, and research institutions will play a pivotal role in ensuring the safety and environmental sustainability of these products. As the market shifts toward cleaner and more responsible production practices, manufacturers of erythrosine and titanium dioxide will need to remain agile and innovative to thrive in the dynamic global marketplace.

In conclusion, erythrosine and titanium dioxide are critical components of various industries, each with its distinct manufacturing processes and applications. By addressing health concerns and embracing sustainable practices, manufacturers can continue to serve the needs of their customers while ensuring safety and compliance in an increasingly conscientious market.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025