8 月 . 29, 2024 09:27 Back to list

Industrial Use of Excellent Dispersion Titanium Dioxide (Anatase) - High-Quality Manufacturing Solutions

Industrial Utilization of Excellent Dispersion Titanium Dioxide Anatase

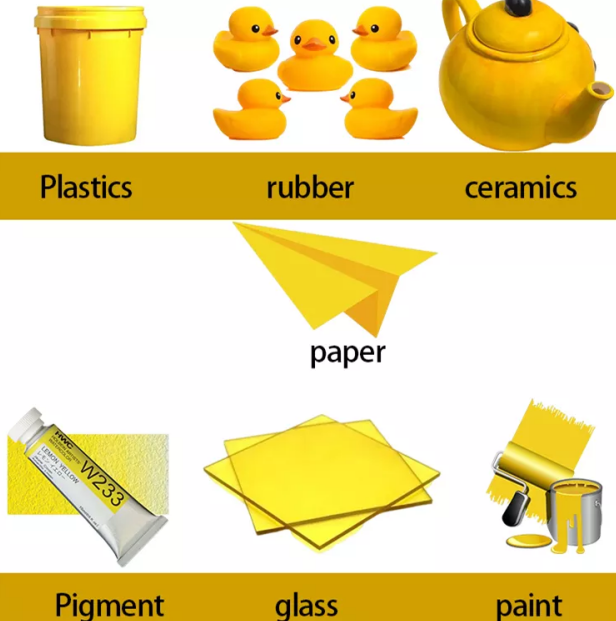

The industrial applications of titanium dioxide (TiO2) have expanded significantly due to its unique properties, particularly when in its anatase form. Renowned for its excellent dispersion characteristics, anatase titanium dioxide is becoming increasingly invaluable across various sectors, including coatings, plastics, cosmetics, and pharmaceuticals.

What is Titanium Dioxide Anatase?

Titanium dioxide exists in three primary crystalline forms rutile, anatase, and brookite, with anatase being the less stable variant. Its exceptional photocatalytic properties, high refractive index, and vibrant whiteness make anatase TiO2 particularly suitable for applications demanding superior pigment qualities. The ease of dispersion of anatase titanium dioxide in various mediums enhances its performance, especially in applications where homogeneous distribution is critical.

Industrial Applications

1. Coatings and Paints The coatings industry has significantly benefited from the use of dispersed anatase titanium dioxide. Its ability to provide excellent opacity, durability, and resistance to weathering enhances the longevity of paints and coatings. Furthermore, the high photocatalytic activity of anatase TiO2 contributes to self-cleaning effects, making treated surfaces inherently cleaner and reducing maintenance costs.

2. Plastics In plastic manufacturing, the incorporation of highly dispersed anatase titanium dioxide improves the mechanical properties of products. It enhances UV stability, prevents yellowing, and offers outstanding whiteness, making it a preferred choice for manufacturers looking to produce high-quality plastic materials.

3. Cosmetics In the cosmetics industry, titanium dioxide is widely used as a pigment and UV filter. The dispersion of anatase TiO2 is critical to achieving a uniform texture in creams, lotions, and sunscreens. Its ability to reflect UV radiation protects the skin from harmful sun exposure, which enhances the safety and effectiveness of cosmetic products.

paper industrial use excellent dispersion titanium dioxide anatase factory

4. Pharmaceuticals As a pharmaceutical excipient, titanium dioxide plays a significant role in drug formulation. The anatase form, when well-dispersed, improves the bioavailability of active ingredients, ensuring that medications are more effective. Its inert nature also makes it suitable for use in tablets and capsules without compromising the therapeutic effects of active compounds.

Challenges in Dispersion

Despite the advantages, achieving excellent dispersion of anatase titanium dioxide can be challenging. Factors such as particle size, agglomeration, and the interaction with other formulation components must be carefully managed. The development of surface modification techniques and the use of dispersants have proven to be effective methods for enhancing the dispersion of TiO2, leading to improvements in various applications.

Future Perspectives

The future of anatase titanium dioxide in industrial applications looks promising. With ongoing research focused on improving its dispersion properties and expanding its uses, we can expect to see more innovative products entering the market. Additionally, the push for sustainable and eco-friendly alternatives in various industries aligns well with the properties of titanium dioxide. Its non-toxic nature and the possibility of recycling make it a frontrunner in the development of sustainable materials.

Conclusion

In conclusion, the industrial use of highly dispersed titanium dioxide anatase showcases its versatility and effectiveness across multiple sectors. As research progresses and technology advances, the potential applications of this remarkable compound are likely to grow, solidifying its status as a critical material in modern industrial practices. The commitment to enhancing its properties and developing new formulations will pave the way for a more sustainable future, maximizing the benefits of this unique mineral.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025