10 月 . 06, 2024 15:14 Back to list

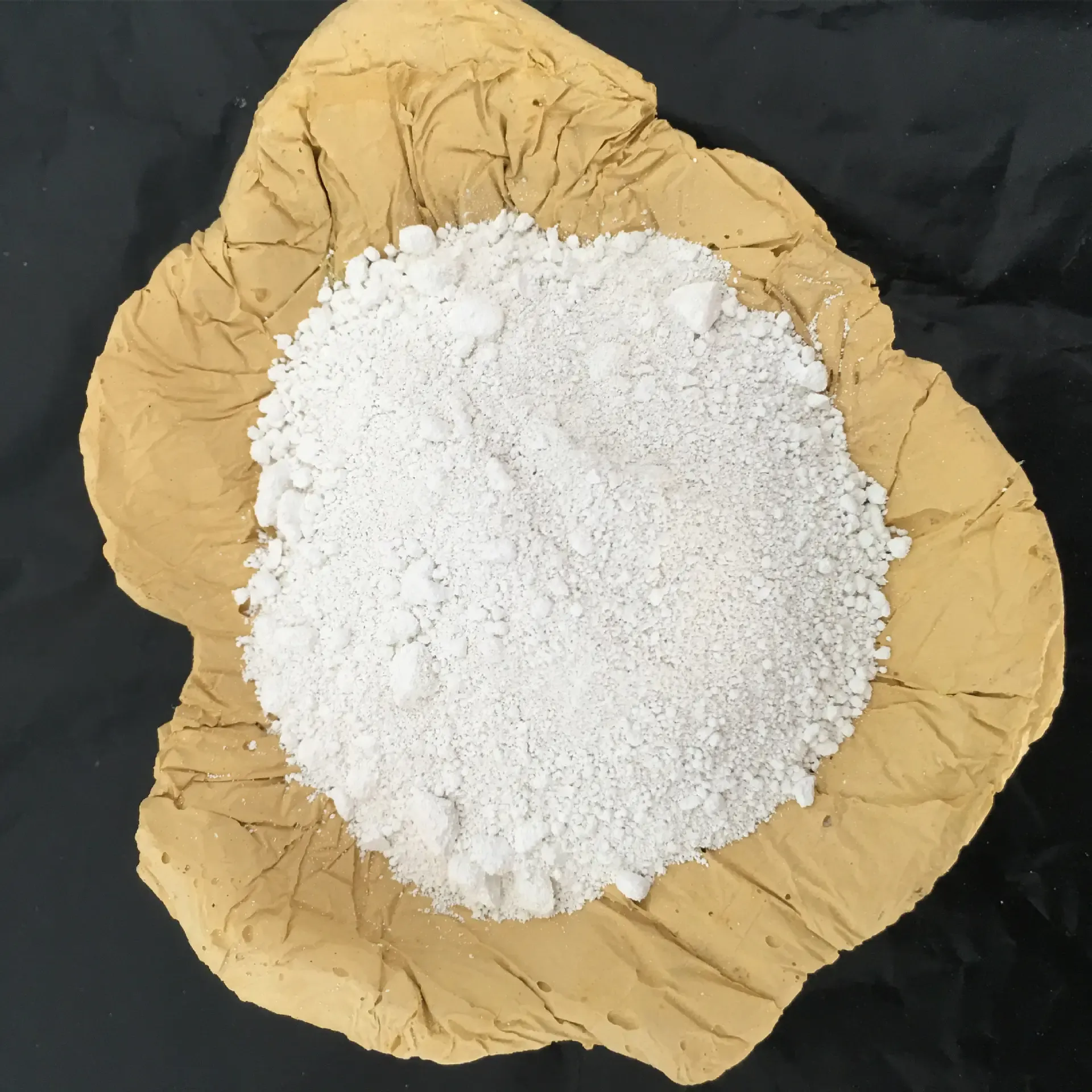

precipitated barium sulfate

Understanding Precipitated Barium Sulfate Properties, Applications, and Production

Barium sulfate (BaSO4) is an inorganic compound known for its high density and excellent chemical stability. It is a white, crystalline solid that is virtually insoluble in water, making it an ideal material for various applications across numerous industries. Precipitated barium sulfate, in particular, has gained prominence due to its unique properties and versatility.

One of the most significant characteristics of precipitated barium sulfate is its particle size and morphology, which can be manipulated during the production process. The manufacturing of this compound primarily involves the precipitation reaction of barium salts, usually barium chloride (BaCl2) or barium nitrate (Ba(NO3)2), with sulfuric acid (H2SO4). This reaction yields a fine, white precipitate of barium sulfate, which can be filtered, washed, and dried for various applications.

The high purity of precipitated barium sulfate makes it a preferred choice in several industries. In the paint and coatings sector, it is used as a pigment and filler due to its excellent opacity and brightness. Moreover, it enhances the durability and weather resistance of coatings, making it invaluable for outdoor applications. In plastics, precipitated barium sulfate acts as a filler that not only improves mechanical properties but also contributes to the opacity and UV resistance of the final product.

precipitated barium sulfate

Another significant application of precipitated barium sulfate is in the medical field, particularly in radiology. It is commonly used as a contrast agent for X-ray imaging and CT scans, allowing for clearer visualization of the gastrointestinal tract. The compound’s high atomic number lends itself to effective imaging, as it absorbs X-rays and helps delineate anatomical structures.

Furthermore, precipitated barium sulfate plays a crucial role in the production of rubber and ceramics. In the rubber industry, it enhances the mechanical properties of products, while in ceramics, it acts as a flux, helping to lower the melting temperature of the mixture and improve the final product's density and strength.

Despite its many advantages, it is essential to handle barium sulfate with care, as barium compounds can be toxic in soluble forms. However, the insolubility of precipitated barium sulfate renders it relatively safe for most applications, particularly when proper safety protocols are adhered to.

In conclusion, precipitated barium sulfate is a versatile compound with a wide range of industrial applications due to its unique properties and high purity. From enhancing paints and plastics to serving vital roles in medical imaging, its significance in modern industry cannot be understated. Ongoing research and technological advancements continue to unveil new potentials for this remarkable compound, ensuring its relevance for years to come.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025