8 月 . 14, 2024 00:36 Back to list

Production of Lithopone and Titanium Dioxide for High-Quality Pigments and Coatings Industry

The Production of Lithopone and Titanium Dioxide An Overview

In the world of pigments and paints, lithopone and titanium dioxide stand out as two of the most significant white pigments utilized across various industries. Their distinctive properties, coupled with diverse applications, have established their indispensable roles in manufacturing, art, and construction. This article aims to provide insights into the production processes of lithopone and titanium dioxide, highlighting their features, benefits, and applications.

Lithopone Production

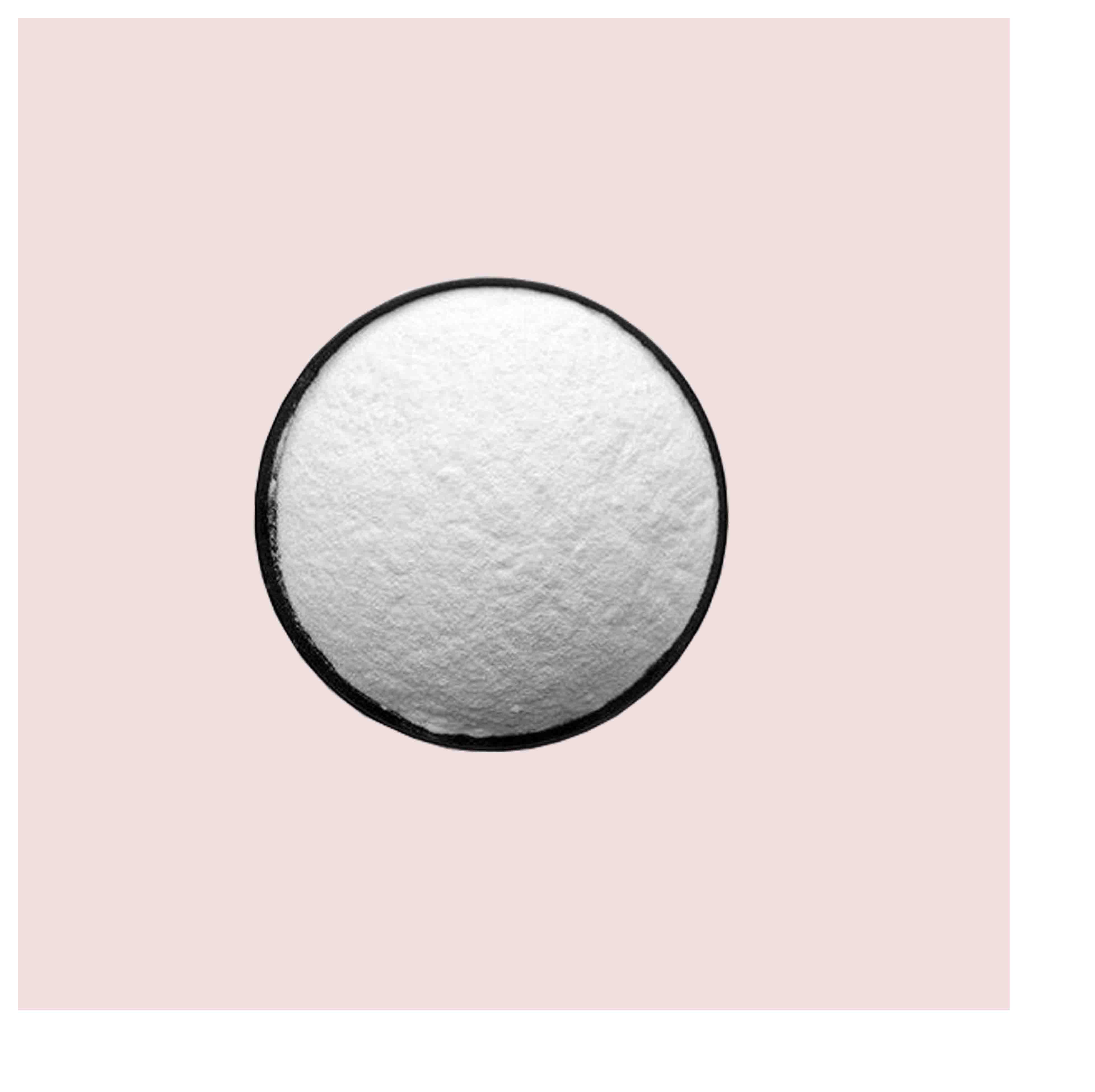

Lithopone is a combination of zinc sulfide and barium sulfate, primarily known for its bright white appearance and excellent opacity. The production of lithopone involves a series of chemical processes that transform natural ores into pure pigments.

The primary raw materials for lithopone production are zinc oxide and barium sulfate, which can be sourced from natural minerals. In the first step, zinc oxide is produced through the thermal decomposition of zinc carbonate. Subsequently, this oxide is mixed with barium sulfate in a specific ratio and co-precipitated with the addition of sulfuric acid. The resulting precipitate is then washed, filtered, and dried, yielding a fine white powder.

Lithopone is favored in various applications, particularly in paint and coating formulations, due to its excellent coverage and durability. Unlike some white pigments, lithopone does not lead to harsh environmental effects, making it a more sustainable option. However, its susceptibility to yellowing upon exposure to light can limit its application in certain niches.

Titanium Dioxide Production

lithopone and titanium dioxide factory

Titanium dioxide (TiO₂) has emerged as the preferred white pigment, especially in industries involving plastics, paper, and coatings

. Its production is primarily based on two methods the sulfate process and the chloride process.The sulfate process begins with the reaction of titanium ore (usually ilmenite) with sulfuric acid. This produces a titanium sulfate solution, which is then further processed to form titanium dioxide. The resultant TiO₂ is often in the form of a bright white powder that exhibits excellent opacity and UV resistance.

On the other hand, the chloride process offers an alternative pathway that is simpler and more environmentally friendly. In this process, titanium tetrachloride is produced by chlorinating titanium ore at high temperatures. The titanium tetrachloride is then oxidized to create titanium dioxide. This process results in titanium dioxide with higher purity levels and better characteristics for specialized applications.

Both processes yield titanium dioxide that is used extensively in paints and coatings, as well as in the food and cosmetics industries due to its non-toxic nature. Its outstanding brightness and reflective properties make it an ideal choice for various applications, effectively outpacing lithopone in terms of market demand and versatility.

Conclusion

The production processes of lithopone and titanium dioxide highlight the evolution of pigment manufacturing. While lithopone serves as a classic choice for various applications, titanium dioxide has dominated the market due to its superior properties and performance. As industries continue to seek sustainable and effective solutions for their pigment needs, research into the development of eco-friendly production methods and alternative materials remains crucial. The continued advancement in pigment technology will not only enhance product quality but also align with the global push for sustainability in manufacturing.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025