10 月 . 02, 2024 10:49 Back to list

tio2 equipment

Understanding TiO2 Equipment Key Technologies and Applications

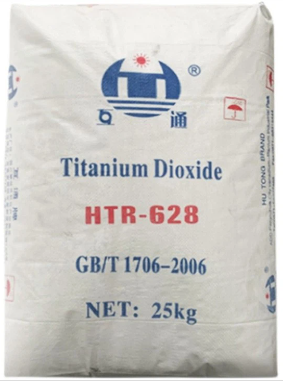

Titanium dioxide (TiO2) is a versatile compound widely used in various industries, including paints, coatings, plastics, and pharmaceuticals. Its unique properties—such as high refractive index, strong ultraviolet light absorption, and chemical stability—make it a preferred choice in these applications. The production and processing of TiO2 demand specialized equipment designed to ensure efficiency and high-quality output. This article delves into the key types of TiO2 equipment, their functions, and significance in industrial applications.

1. TiO2 Production Equipment

The initial step in TiO2 manufacturing involves extracting titanium from its ores, primarily ilmenite and rutile. Two primary processes are employed the sulfate process and the chloride process. Each of these requires specialized equipment.

In the sulfate process, ilmenite is treated with sulfuric acid, leading to the formation of titanium sulfate. The equipment essential for this process includes reactors capable of withstanding corrosion, where high temperatures and pressures are maintained. Key components include mixing tanks, heat exchangers, and evaporators for concentrating the titanium sulfate solution.

The chloride process, on the other hand, involves the conversion of rutile ore into titanium tetrachloride (TiCl4) using chlorine gas. This process requires high-purity equipment, such as fluidized bed reactors and distillation columns, to ensure the separation and purification of TiCl4 before it is converted into TiO2 through oxidation.

2. TiO2 Pigment Production Equipment

Once titanium dioxide is produced, it is transformed into pigments. These pigments are essential components in coatings and plastics, providing whiteness and opacity. The equipment needed for TiO2 pigment production includes milling machinery, which grinds the TiO2 particles to specific sizes, and classifiers that ensure uniform particle size distribution.

tio2 equipment

Additionally, spray dryers are often utilized to produce powdered pigments. They convert the liquid slurry of TiO2 into fine powders through the process of atomization and drying. The design and efficiency of this equipment are crucial as they directly impact the quality of the final product.

3. Quality Control and Testing Equipment

Ensuring the quality of TiO2 is critical, especially in industries such as cosmetics and food where purity is paramount. Various testing equipment is employed to analyze the chemical composition, particle size, and surface properties of TiO2. Techniques like X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are commonly used. These tools help verify that the TiO2 meets industry standards.

4. Environmental and Safety Equipment

Given the environmental concerns surrounding industrial processes, equipment that ensures compliance with safety and environmental regulations is essential. Dust collectors, scrubbers, and filtration systems are integral to TiO2 manufacturing facilities. They minimize emissions and ensure that a safe and clean working environment is maintained for personnel.

Conclusion

TiO2 equipment plays a crucial role in the efficient and safe manufacturing of titanium dioxide. From production and pigment processing to quality control and environmental safety, each piece of equipment contributes significantly to the overall productivity and quality assurance in the TiO2 industry. As the demand for TiO2 continues to rise due to its wide-ranging applications, advancements in equipment technology will likely remain a focal point to enhance efficiency and sustainability in this vital sector.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025