10 月 . 21, 2024 17:46 Back to list

Titanium Dioxide Applications in Plastic Manufacturing and Their Benefits for Industry

The Role of Titanium Dioxide in Plastic Manufacturing

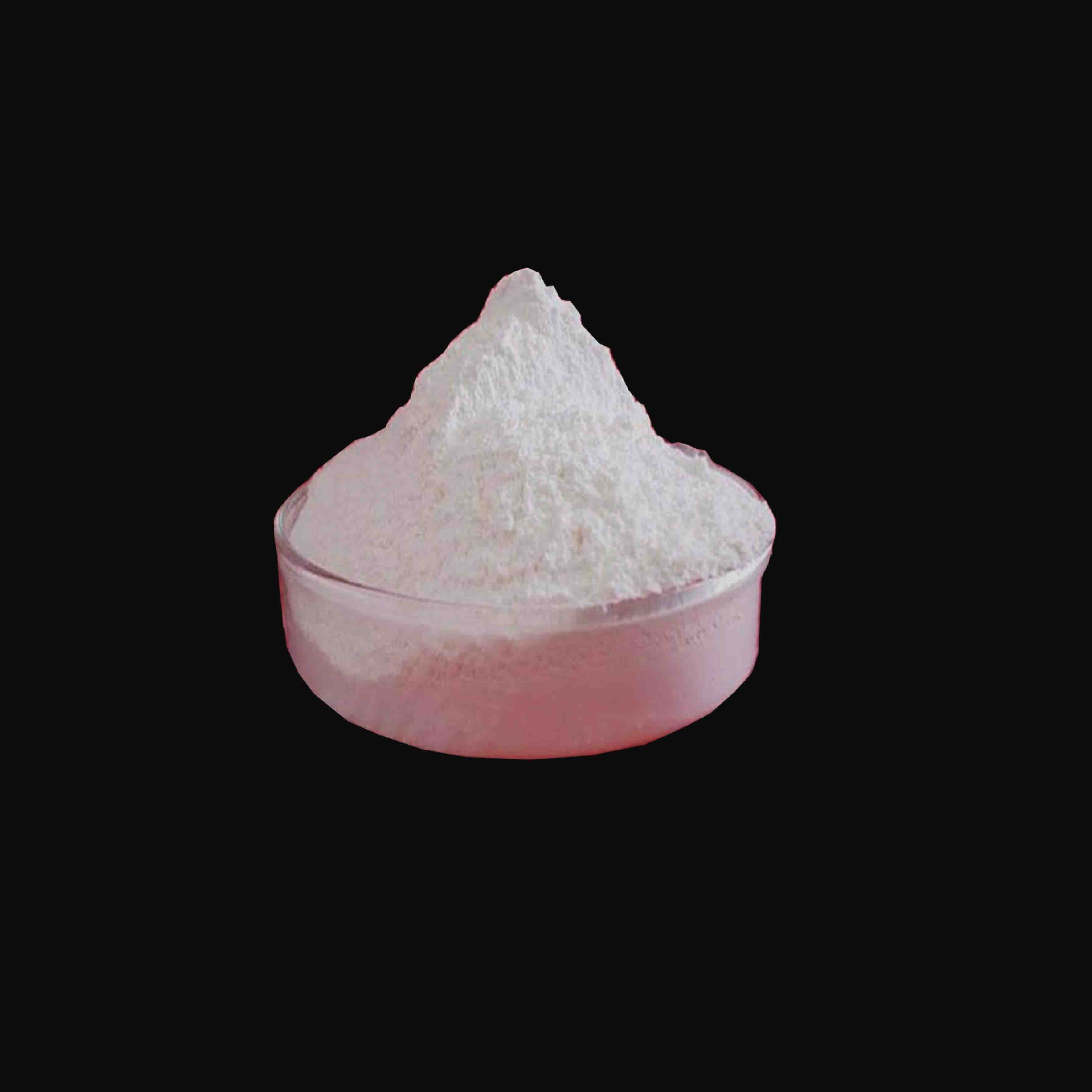

Titanium dioxide (TiO2) is an inorganic compound renowned for its exceptional properties, particularly its high refractive index and excellent UV resistance. This widely used white pigment is a staple in various industries, including coatings, cosmetics, and notably, plastic manufacturing. As the demand for high-quality, durable, and aesthetically pleasing plastic products continues to rise, the importance of TiO2 in this sector cannot be overstated.

What is Titanium Dioxide?

Titanium dioxide is a white, inorganic pigment that is non-toxic and environmentally friendly. It is derived from titanium ore and is produced through two primary processes the sulfate process and the chloride process. The resulting pigment is known for its brightness, durability, and ability to scatter light, making it a key ingredient in achieving the desired opacity and whiteness in plastic products.

Applications in Plastic Manufacturing

In plastic manufacturing, titanium dioxide is primarily used as a pigment to provide whiteness and opacity to products. This is particularly important in the production of opaque plastics, where transparency is not desired. TiO2 improves the aesthetic appeal of plastic items, ensuring that they are visually attractive and capable of masking underlying colors or materials.

Moreover, the presence of titanium dioxide in plastics enhances their mechanical properties. It contributes to improved rigidity and durability, making the final products more resistant to wear and tear. In terms of performance, TiO2 acts as a UV stabilizer, protecting plastics from degradation caused by exposure to sunlight. This is especially important for products used in outdoor applications, where UV exposure can lead to significant deterioration over time.

Environmental Considerations

As industries increasingly focus on sustainable practices, titanium dioxide stands out because of its environmentally friendly profile. It is non-hazardous and does not contribute to environmental pollution, unlike some synthetic dyes and pigments. This quality aligns with the growing demand for sustainable and eco-friendly products in consumer markets. By incorporating TiO2, manufacturers can produce plastics that not only meet aesthetic standards but also adhere to environmental regulations and consumer expectations.

tio2 used in plastic manufacturer

The Global Market for TiO2 in Plastics

The global market for titanium dioxide is witnessing significant growth, driven by an increase in plastic production. Various sectors, including packaging, automotive, consumer goods, and construction, are major consumers of plastic materials. With the continuous expansion of these industries, the demand for TiO2 is expected to rise correspondingly. According to market research, the use of titanium dioxide in plastic applications is anticipated to grow steadily, particularly in emerging economies where industrialization is accelerating.

Furthermore, advancements in technology and production processes are paving the way for enhanced formulations of titanium dioxide, making it even more effective as a plastic additive. For instance, the development of surface-treated TiO2 can enhance its dispersion in polymer matrices, leading to even greater performance improvements in final products.

Challenges and Innovations

Despite its advantages, the use of titanium dioxide in plastics is not without challenges. Concerns have been raised regarding the potential health effects of TiO2, particularly when it exists in nanoparticle form. Ongoing research aims to better understand these effects and ensure safe handling practices in manufacturing environments. The industry is closely monitoring regulatory changes and scientific findings to adapt accordingly and maintain safety standards.

Innovations in alternative pigments and additives are also challenging the dominance of titanium dioxide. Researchers are exploring bio-based pigments and other environmentally friendly alternatives that could potentially replace TiO2 in certain applications. However, due to its unique properties, TiO2 remains a preferred choice in many scenarios.

Conclusion

Titanium dioxide plays a crucial role in plastic manufacturing, contributing to the enhancement of product quality through improved coloration, UV resistance, and mechanical properties. As global demand for plastics continues to grow, the importance of TiO2 is likely to remain significant. Industry stakeholders must navigate the challenges posed by health concerns and competition from alternative materials while leveraging the advantages of titanium dioxide. Ultimately, the continued use of TiO2 in the plastic sector will not only support the production of high-quality materials but also align with the ongoing pursuit of sustainability in manufacturing practices. As technology advances, the future looks promising for both titanium dioxide and plastic manufacturing, ensuring the creation of robust, aesthetically pleasing, and environmentally responsible products.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025